Rain-erosion-proof and elastic protection coating for antenna housing and preparation method thereof

A technology for protecting coatings and radome, applied in polyurea/polyurethane coatings, coatings, pigment pastes, etc., can solve the problem that radome is easily washed by raindrops, hail, etc., radome is damaged, and the radome structure safety and electrical damage are affected. Performance and other issues, to achieve the effect of ensuring elongation at break and rebound performance, improving wear resistance, and elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

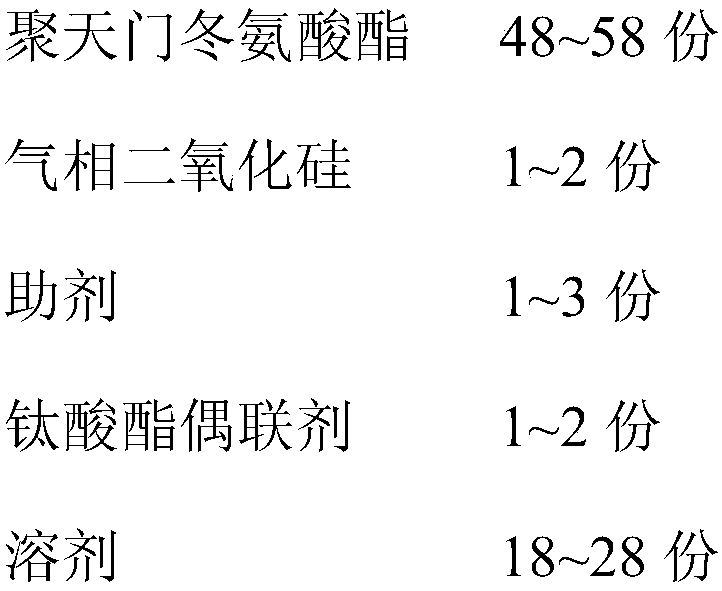

[0050] (1) Add 50g NH-1420, 20g n-butyl acetate, 0.5g dispersant, 0.1g leveling agent, 0.3g defoamer, 0.5g ultraviolet absorber, 1.2g titanate coupling agent into the cylinder, After stirring evenly, add 1g of TS-100 in two batches, stir and disperse evenly, and then filter out the material to obtain component A of the anti-rain erosion elastic protective coating for radome.

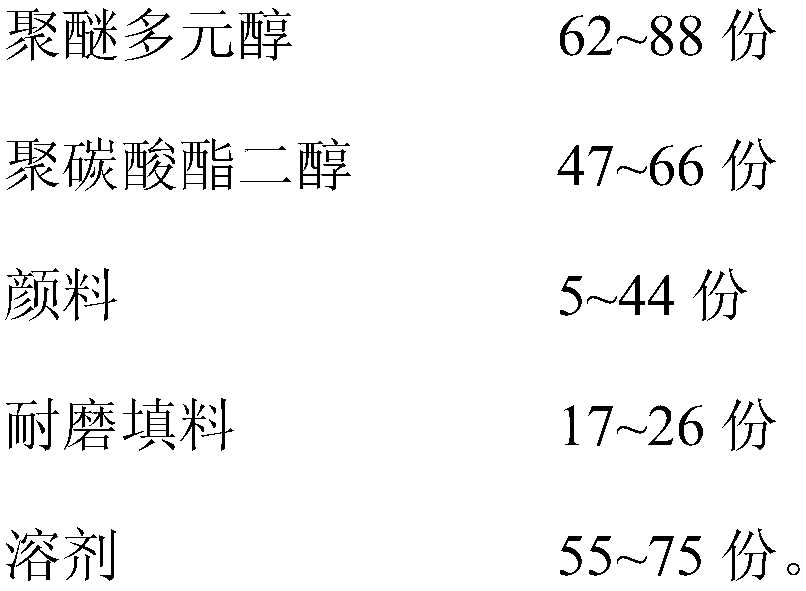

[0051] (2) Add 72g of N-210, 55g of T5650J, and 60g of xylene into the pulling tank, stir evenly, add 38g of titanium dioxide and 20g of silicon carbide, grind to a fineness of ≤30μm through a grinding and dispersing equipment, and then filter out the material to obtain the radome anti- Hydroxyl resin color paste for component B of rain erosion elastic protective coating.

[0052] (3) Put 170g of hydroxyl resin color paste, 5.4g of trimethylolpropane, and 22g of xylene into the reaction bottle, raise the temperature to 130°C-135°C under the protection of inert gas, reflux for dehydration reaction for 2 h...

Embodiment 2

[0054] (1) Add 44g NH-1520, 26g methyl isobutyl ketone, 0.8g dispersant, 0.05g rheological additive, 0.5g defoamer, 0.8g ultraviolet absorber, 1.4g titanate coupling agent to pull Add 1.2g of ED-30 in three batches after stirring evenly, stir and disperse evenly, and then filter out the material to obtain component A of the anti-rain erosion elastic protective coating for radome.

[0055] (2) Add 80g of N-204, 48g of T5651, and 72g of n-butyl acetate into the tank, stir evenly, add 17g of organic yellow and 24g of boron nitride, grind to a fineness of ≤30μm through a grinding and dispersing equipment, and then filter out the material to obtain Hydroxyl resin colorant for component B of rain-corrosion resistant elastic protective paint for radome.

[0056](3) Put 200g of hydroxyl resin color paste, 2.5g of pentaerythritol, and 36g of xylene into a reaction flask, heat up to 130°C to 135°C under the protection of an inert gas, reflux for dehydration for 2 hours, then cool down t...

Embodiment 3

[0058] (1) Mix 26gNH-1220, 28gNH-1521, 17g n-butyl acetate, 6g n-pentyl acetate, 0.7g dispersant, 0.2g leveling agent, 0.5g defoamer, 0.7g ultraviolet absorber, 1.5g titanium Add the ester coupling agent into the pull tank, stir evenly, add 1.4g ED-30 in two batches, stir and disperse evenly, filter out the material, and obtain the first component of the rain-erosion resistant elastic protective coating for the radome.

[0059] (2) Add 66g of N-204, 18g of T5650E, 40g of T5651, 30g of xylene, and 30g of methyl isobutyl ketone into the cylinder, stir evenly, add 8g of carbon black and 23g of silicon carbide, and grind to a fineness of ≤30μm by grinding and dispersing equipment After filtering and discharging, the hydroxyl resin color paste for the second component of the anti-rain erosion elastic protective paint for the radome is obtained.

[0060] (3) Put 167g of hydroxyl resin color paste, 4.4g of glycerol, and 29g of xylene into the reaction bottle, raise the temperature to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com