Fast-cured, high-performance and low-cost unsaturated polyester prepreg and preparation method thereof

A rapid curing and unsaturated technology, applied in the field of polymer materials, can solve problems such as fire hazards, changes in the composition ratio of resin components, and low work efficiency, so as to achieve a stable and controllable reaction process, improve manufacturing efficiency, and reduce molding costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

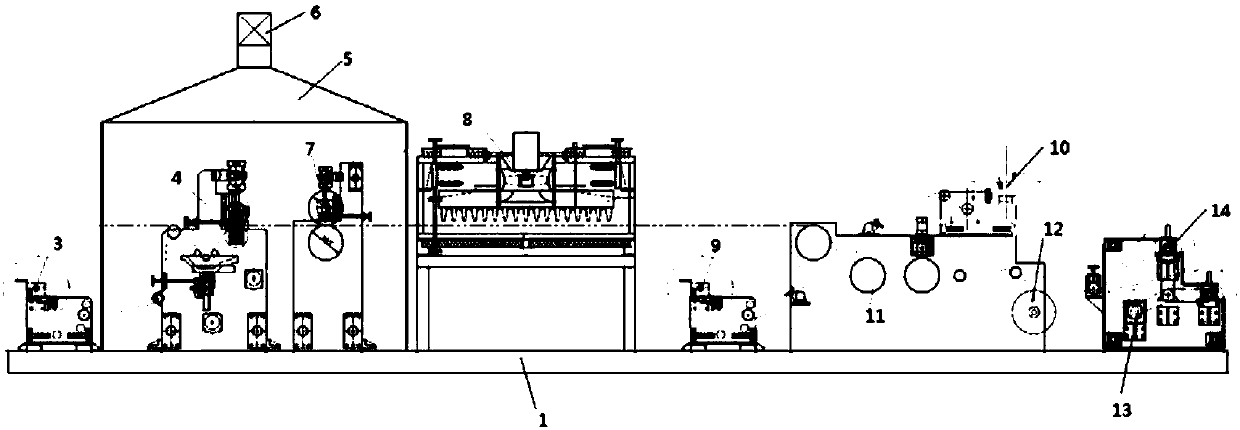

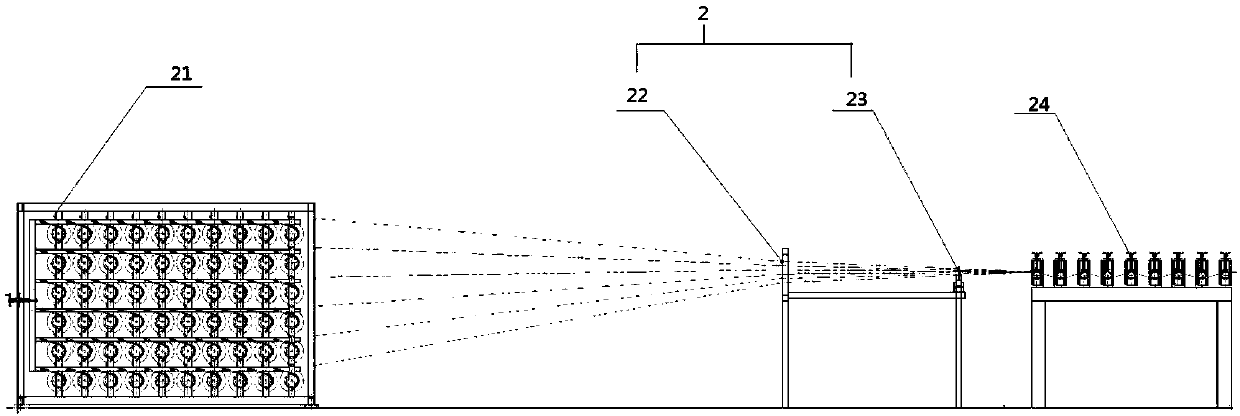

[0032] A preparation method of fast curing, high-performance and low-cost unsaturated polyester prepreg, the preparation method is as follows:

[0033] (a) Preheat the reactor at 40°C for 1 hour, weigh 5000g of vinyltoluene and keep 1000ml in the beaker for use, add the rest to the reactor, weigh 15000g of unsaturated polyester and stabilizer and add it to the reactor , add hydroquinone 10g, stir and mix evenly to obtain mixed solution A;

[0034] (b) Weigh 600g of benzoyl peroxide and dissolve it in 500ml of vinyltoluene, wash with the remaining 500ml of vinyltoluene, then add it to the reaction kettle, stir with the mixture A for 1min, and mix well to obtain the mixture B;

[0035] (c) Weigh 200g of organic montmorillonite and 400g of silicon dioxide into the reaction kettle, stir with the mixed solution B for 3min, and mix well to obtain the mixed solution C;

[0036] (d) Weigh the coupling agent KH-570 into the reaction kettle, stir with the mixed solution C for 2 minutes, ...

Embodiment 2

[0048] According to the resin matrix obtained in Example 1, the mass percent content of the resin matrix was controlled to be 50% in the same manner to obtain an unsaturated polyester prepreg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com