Preparation and application of low-toxicity and high-efficiency polymerization inhibitor for acrylonitrile device

A high-efficiency polymerization inhibitor and acrylonitrile technology, applied in the purification/separation of carboxylic acid nitrile, organic chemistry, etc., can solve the problems of flying dust, affecting the health of employees, material loss, etc., and achieve low freezing point, significant economic benefits and Social benefit, effect of extending operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

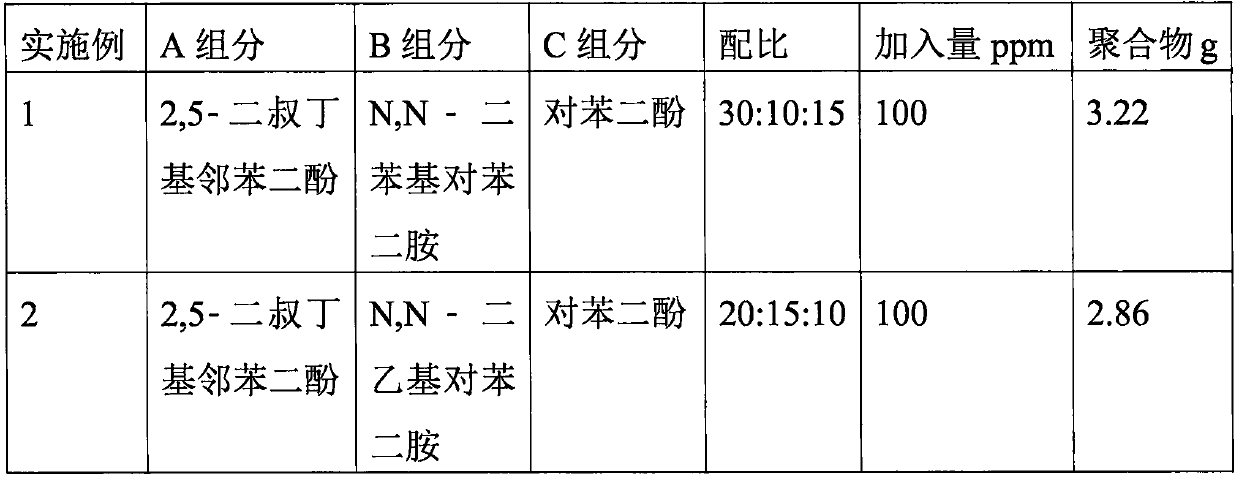

Embodiment 1

[0012] Example 1 Get 1000g of acrylonitrile to remove the polymerization inhibitor, do total reflux operation (operating temperature: 100°C, time: 30 minutes) in the following device, add 100ppm polymerization inhibitor respectively, then measure the polymer content in the product as 3.22 g.

Embodiment 2

[0013] Embodiment 2 Get 1000g of acrylonitrile for removing the polymerization inhibitor, do total reflux operation (operating temperature: 100°C, time: 30 minutes) in the following device, add 100ppm polymerization inhibitor respectively, then measure the polymer content in the product as 2.86g.

Embodiment 3

[0014] Embodiment 3 Get 1000g of acrylonitrile for removing the polymerization inhibitor, do total reflux operation (operating temperature: 100°C, time: 30 minutes) in the following device, add 100ppm polymerization inhibitor respectively, then measure the polymer content in the product as 2.14g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com