High-temperature-resistant igniter ejector

A catapult, high-temperature-resistant technology, which is applied in aircrafts, aerospace vehicles, and docking devices for aerospace vehicles, etc., can solve the problems of affecting the speed and thrust of the catapult, reducing the speed of structural heat conduction, and decreasing the shear strength rapidly. The effect of reducing the contact area, reducing the impact, increasing the path of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

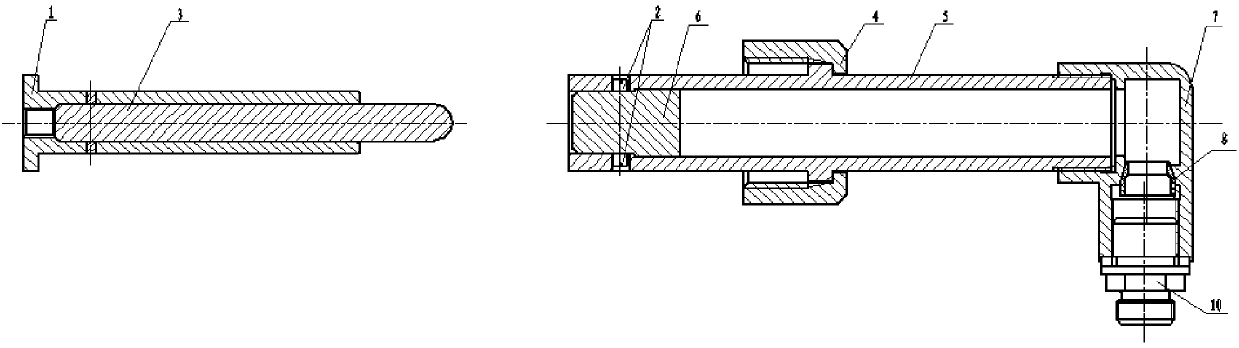

[0029] Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

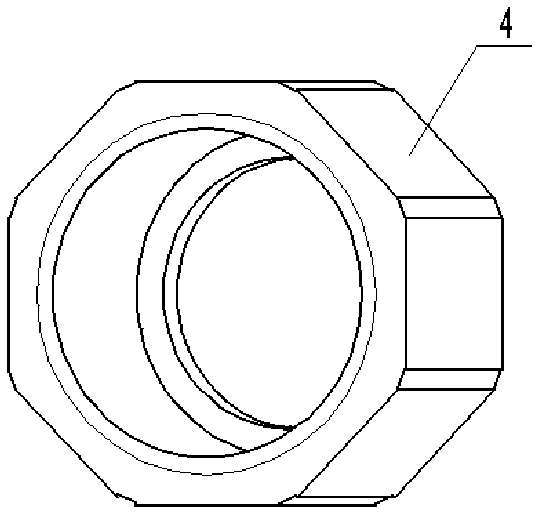

[0030] Such as figure 1 As shown, a high temperature resistant pyrotechnic catapult of the present invention includes an inner cylinder assembly, an outer cylinder assembly, a medicine box assembly and a shear pin 2, the inner cylinder assembly and the outer cylinder assembly are fixed by the shear pin 2, and the outer cylinder assembly and The medicine box assembly is connected; the outer aircraft protective cover is connected with the inner cylinder assembly, and the outer aircraft is connected with the outer cylinder assembly.

[0031] The inner cylinder assembly includes an inner cylinder 1 and a sliding rod 3; the material of the inner cylinder 1 is TA15, one end of the inner cylinder 1 is a flange, and the flange end has an internal thread, the thickness of the flange is smaller than the length of the threaded section, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com