A kind of fluorosilicone waterproof and oil-repellent agent and the method utilizing one-pot method to carry out synthesis thereof

A water- and oil-repellent, fluorine-silicon technology, used in antifouling/underwater coatings, biocide-containing paints, coatings, etc., can solve the problems of difficult handling, high cost, and difficult to adhere to the glass surface, and achieve a wide range of application prospects , the effect of low cost and shortened response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

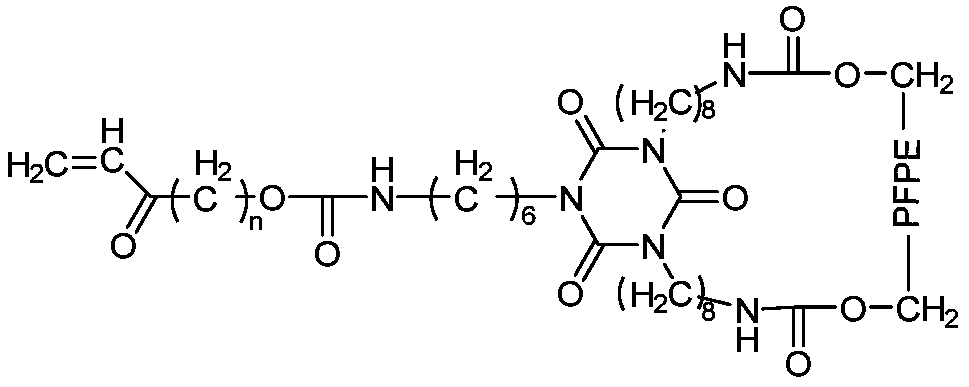

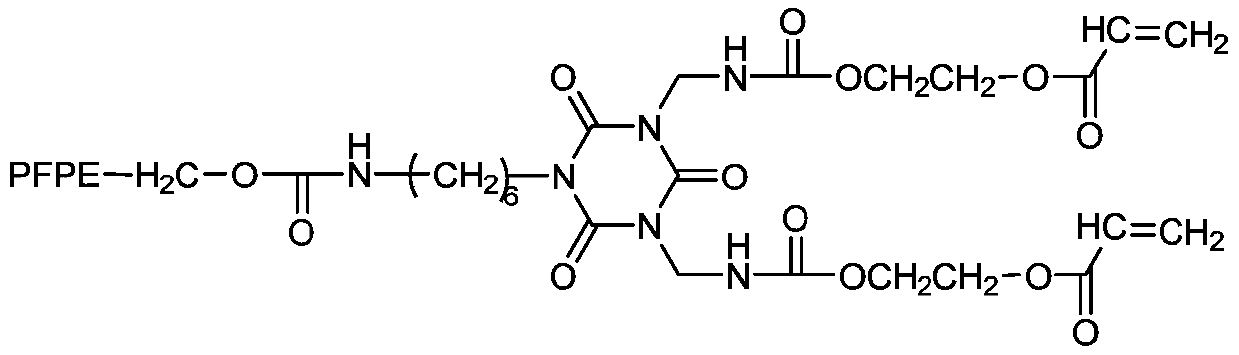

Image

Examples

Embodiment 1

[0039]The present embodiment provides a method for synthesizing a fluorosilicone water-repellent and oil-repellent agent by a one-pot method, namely: first add 400g perfluoropolyether (PFPECOF ), then slowly add 11.6g (1.0 equivalent) of allyl alcohol dropwise through the dropping funnel at room temperature, continue to react for 2h after dropping, remove the unreacted low-boiling raw material under reduced pressure, and obtain the perfluoropolyether acid allyl Esters (PFPECOOCH 2 CH=CH 2 ) continue to stay in the four-necked flask for subsequent use. Add 36.4g (1.5 equivalent) trimethoxysilane and 76.2mg (0.1% equivalent) Karstedt catalyst to the above-mentioned four-necked flask equipped with the allyl perfluoropolyetherate, react at 80°C for 12h, and finally distill Remove unreacted low-boiling raw materials and finally obtain 381.6g colorless target product perfluoropolyether acid trimethoxysilyl propyl ester {PFPECOOCH 2 CH 2 CH 2 Si(OMe) 3}, the yield was 88.3%.

Embodiment 2

[0041] The present embodiment provides a method for synthesizing a fluorosilicone water-repellent and oil-repellent agent by a one-pot method, namely: first add 400g perfluoropolyether (PFPECOF ), then slowly add 17.4g (1.5 equivalents) of propylene alcohol dropwise through the dropping funnel at room temperature, continue to react for 2h after dropping, and remove unreacted low-boiling raw materials under reduced pressure, and the obtained perfluoropolyether acid allyl Esters (PFPECOOCH 2 CH=CH 2 ) continue to stay in the four-necked flask for subsequent use. Add 36.4g (1.5 equivalent) trimethoxysilane and 76.2mg (0.1% equivalent) Karstedt catalyst to the above-mentioned four-necked flask equipped with the allyl perfluoropolyetherate, react at 80°C for 12h, and finally distill Remove unreacted low-boiling raw materials and finally obtain 391.1g colorless target product perfluoropolyether acid trimethoxysilyl propyl ester {PFPECOOCH 2 CH 2 CH 2 Si(OMe) 3}, the yield was ...

Embodiment 3

[0043] The present embodiment provides a method for synthesizing a fluorosilicone water-repellent and oil-repellent agent by a one-pot method, namely: first add 400g perfluoropolyether (PFPECOF ), then slowly add 17.4g (1.5 equivalents) of propylene alcohol dropwise through the dropping funnel at room temperature, continue to react for 4h after dropping, and remove unreacted low-boiling raw materials under reduced pressure, and the obtained perfluoropolyether acid allyl Esters (PFPECOOCH 2 CH=CH 2 ) continue to stay in the four-necked flask for subsequent use. Add 36.4g (1.5 equivalent) trimethoxysilane and 76.2mg (0.1% equivalent) Karstedt catalyst to the above-mentioned four-necked flask equipped with the allyl perfluoropolyetherate, react at 80°C for 12h, and finally distill Remove unreacted low-boiling raw materials and finally obtain 391.5g colorless target product perfluoropolyether acid trimethoxysilyl propyl ester {PFPECOOCH 2 CH 2 CH 2 Si(OMe) 3}, the yield was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com