A kind of compound with anti-pollution effect and preparation method thereof

A compound and anti-pollution technology, applied in anti-fouling/underwater coatings, biocide-containing paints, coatings, etc., can solve the problems of high cost, difficult handling, and difficult glass surface adhesion, etc., to achieve increased smoothness, Wide application prospects and the effect of shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

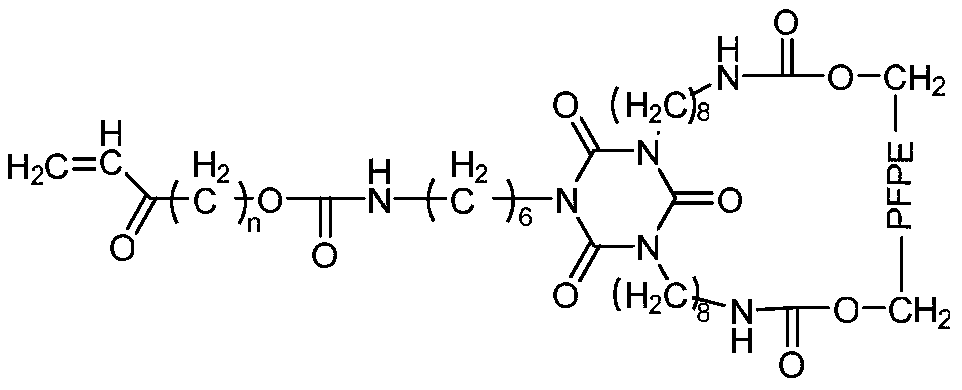

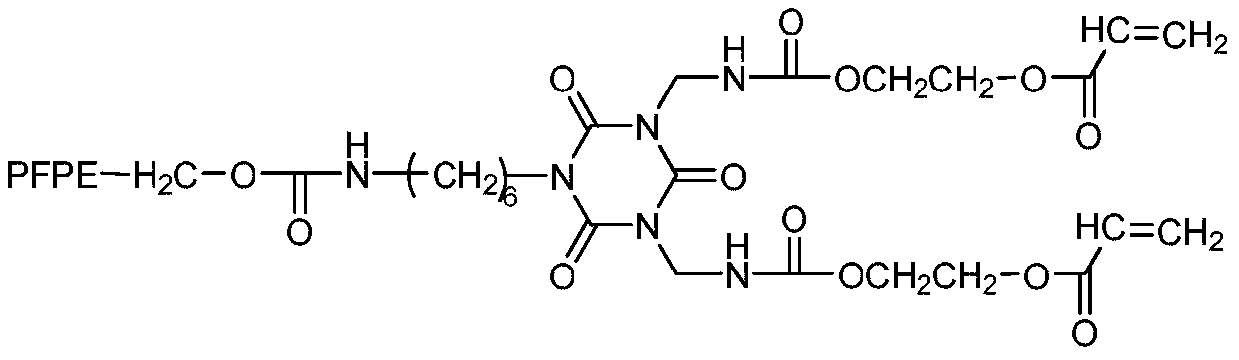

Method used

Image

Examples

Embodiment 1

[0041] This embodiment relates to a preparation method of an anti-pollution compound, comprising the steps of:

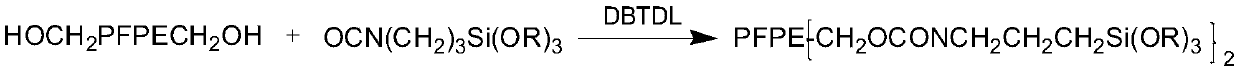

[0042] 1) Under anhydrous and oxygen-free conditions, add 80g perfluoropolyether (1mol) (HOCH 2 PFPECH 2 OH), then add 400g 3M 7200 fluorine-containing solvent to dissolve, then slowly add 6.15g 3-isocyanatopropyltrimethoxysilane (1.5mol) dropwise through the dropping funnel at room temperature, stir for several minutes and then dropwise add 4 Drip condensation agent dibutyltin dilaurate reagent (DBTDL);

[0043] 2) Raise the temperature to 50 degrees Celsius to react and conduct IR detection every half an hour to detect whether 3369 disappears on the infrared spectrum and whether there are signals from 1235 and 1380. After 3369 completely disappears, continue the reaction for 1 hour. The low-boiling point 3M 7200 fluorine-containing solvent and the raw material 3-isocyanatopropyltrimethoxysilane were distilled off under reduced pressure, and the product was washe...

Embodiment 2

[0045] This embodiment relates to a preparation method of an anti-pollution compound, comprising the steps of:

[0046] 1) Under anhydrous and oxygen-free conditions, first add 80g of perfluoropolyether (HOCH 2 PFPECH 2 OH) (1mol), then add 400g 3M 7200 fluorine-containing solvent to dissolve, then slowly add 8.2g 3-isocyanatopropyltrimethoxysilane (2.0mol) dropwise through the dropping funnel at room temperature, stir for several minutes and then Add 4 drops of condensing agent dibutyltin dilaurate reagent (DBTDL);

[0047] 2) Raise the temperature to 50 degrees Celsius to react and conduct IR detection every half an hour to detect whether 3369 disappears on the infrared spectrum and whether there are signals from 1235 and 1380. After 3369 completely disappears, continue the reaction for 1 hour. The low-boiling point 3M 7200 fluorine-containing solvent and the raw material 3-isocyanatopropyltrimethoxysilane were distilled off under reduced pressure, and the product was wash...

Embodiment 3

[0049] This embodiment relates to a preparation method of an anti-pollution compound, comprising the steps of:

[0050] 1) Under anhydrous and oxygen-free conditions, first add 80g of perfluoropolyether (HOCH 2 PFPECH 2 OH) (1mol), then add 400g 3M 7200 fluorine-containing solvent to dissolve, then slowly add 10.3g 3-isocyanatopropyltrimethoxysilane (2.5mol) dropwise through the dropping funnel at room temperature, stir for several minutes and then Add 4 drops of condensing agent dibutyltin dilaurate reagent (DBTDL);

[0051] 2) Raise the temperature to 50 degrees Celsius to react and conduct IR detection every half an hour to detect whether 3369 disappears on the infrared spectrum and whether there are signals from 1235 and 1380. After 3369 completely disappears, continue the reaction for 1 hour. The low-boiling point 3M 7200 fluorine-containing solvent and the raw material 3-isocyanatopropyltrimethoxysilane were distilled off under reduced pressure, and the product was was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com