Preparation method of silver/graphene/zinc oxide composite material capable of degrading formaldehyde

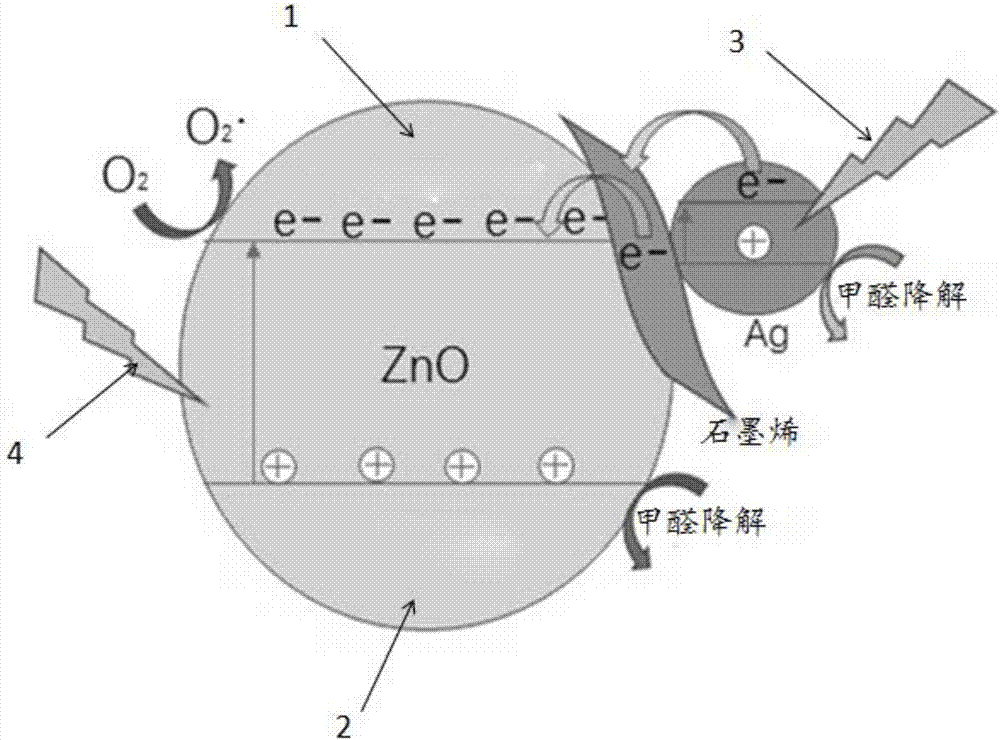

A composite material and graphene technology, applied in chemical instruments and methods, botanical equipment and methods, catalyst activation/preparation, etc., to achieve enhanced photocatalytic activity, effective energy conversion, and improved charge separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of preparation method of the Ag / graphene / ZnO composite material that can degrade formaldehyde comprises the following steps:

[0032] (1) Preparation of nano ZnO particles: Measure 50 mL of 1 mol / L Zn(NO3) 2 solution into a 200 ml beaker, and add 50 mL of 2 mol / L NaOH solution while stirring. Let stand for a day. The resulting precipitate was filtered, washed, and dried in an oven at 80°C. The dried precipitate was roasted in a muffle furnace for 3 h. ZnO nanoparticles can be obtained by grinding after cooling;

[0033] (2) Preparation of Ag / graphene / ZnO: Ag nanoparticles are uniformly dispersed on the ZnO nanoparticles obtained in step (1) by physical vapor deposition to form Ag / ZnO composite nanoparticles. In the physical vapor deposition process, first Vacuumize to 0.05 Pa, and keep the vacuum degree not lower than 0.1Pa, the mass ratio of ZnO and Ag is 20:1; then use Ag / ZnO composite nanoparticles as the matrix, methane as the carbon source, at an air pres...

Embodiment 2

[0037] A kind of preparation method of the Ag / graphene / ZnO composite material that can degrade formaldehyde comprises the following steps:

[0038] (1) Preparation of nano ZnO particles: Measure 50 mL of 1 mol / L Zn(NO3) 2 solution into a 200 ml beaker, and add 50 mL of 2 mol / L NaOH solution while stirring. Let stand for a day. The resulting precipitate was filtered, washed, and dried in an oven at 80°C. The dried precipitate was roasted in a muffle furnace for 3 h. ZnO nanoparticles can be obtained by grinding after cooling;

[0039] (2) Preparation of Ag / graphene / ZnO: Ag nanoparticles are uniformly dispersed on the ZnO nanoparticles obtained in step (1) by physical vapor deposition to form Ag / ZnO composite nanoparticles. In the physical vapor deposition process, first Vacuumize to 0.05 Pa, and keep the vacuum degree not lower than 0.1Pa, the mass ratio of ZnO and Ag is 20:1; then use Ag / ZnO composite nanoparticles as the matrix, methane as the carbon source, at an air pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com