Method for preparing waterproof antibacterial ceiling material

A ceiling, waterproof technology, applied in the fields of botanical equipment and methods, fungicides, chemicals for biological control, etc., can solve the problems of poor antibacterial effect, low strength, poor waterproof performance, etc., to improve waterproof performance. and antibacterial properties, enhance affinity, and improve the effect of bactericidal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

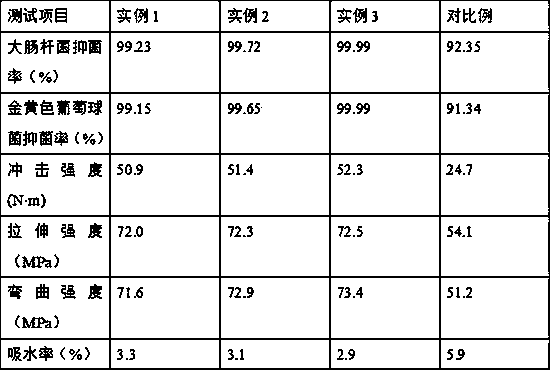

example 1

[0020] Weigh 65g of gypsum rock, put it into a pulverizer, grind and pulverize it for 7 minutes, pass it through a 100-mesh sieve, collect the sieved powder, put the sifted powder into a muffle furnace, calcinate at a temperature of 240°C for 1 hour, and cool naturally to room temperature to obtain For calcined gypsum, mix calcined gypsum and silver nitrate solution with a mass fraction of 32% in a beaker and stir for 6 minutes according to a mass ratio of 1:3 to obtain a stirred liquid, and adjust the pH of the stirred liquid with a mass fraction of 12% nitric acid solution to 6. Put the stirring solution in a dark greenhouse and mix and stir for 45 minutes, filter under reduced pressure, remove the filtrate, take out the filter residue, continue to put the filter residue in an oven, and dry it for 20 minutes at a temperature of 70°C to obtain Self-made silver-loaded gypsum; weigh 65g of nano-titanium dioxide and pour it into a kiln, activate it at 200°C for 16 minutes to obta...

example 2

[0022]Weigh 75g of gypsum rock, put it into a pulverizer, grind and pulverize it for 89min, pass through a 100-mesh sieve, collect the sieved powder, put the sifted powder into a muffle furnace, calcinate at a temperature of 280°C for 1.5h, and cool naturally to room temperature. To obtain calcined gypsum, mix calcined gypsum and silver nitrate solution with a mass fraction of 32% in a beaker and stir for 7 minutes according to a mass ratio of 1:3 to obtain a stirred solution, and adjust the pH of the stirred solution with a 12% nitric acid solution to 7, then put the stirring solution in a dark greenhouse and mix and stir for 55 minutes, then filter under reduced pressure, remove the filtrate, take out the filter residue, continue to put the filter residue in an oven, and dry it for 25 minutes at a temperature of 80°C. Obtain self-made silver-loaded gypsum; weigh 55g of nano-titanium dioxide and pour it into a kiln, activate it at 180°C for 14 minutes to obtain activated nano-...

example 3

[0024] Weigh 85g of gypsum rock, put it into a pulverizer, grind it for 9 minutes, pass it through a 100-mesh sieve, collect the sieved powder, put the sifted powder into a muffle furnace, calcinate at 320°C for 2 hours, and cool naturally to room temperature to obtain For calcined gypsum, mix calcined gypsum and silver nitrate solution with a mass fraction of 32% in a beaker and stir for 8 minutes according to a mass ratio of 1:3 to obtain a stirred liquid, and adjust the pH of the stirred liquid with a mass fraction of 12% nitric acid solution to 8. Put the stirring solution in a dark greenhouse and mix and stir for 60 minutes, then filter under reduced pressure, remove the filtrate, take out the filter residue, continue to put the filter residue in an oven, and dry it for 30 minutes at a temperature of 90°C to obtain Self-made silver-loaded gypsum; weigh 65g of nano-titanium dioxide and pour it into a kiln, activate it at 200°C for 16 minutes to obtain activated nano-titaniu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com