Method for preparing active carbon by use of semicoke and coal tar and active carbon obtained by method

A technology for preparing activated carbon and activated carbon, which is applied in the field of activated carbon, can solve the problems of cumbersome procedures, low production efficiency, acid corrosion resistance, and alkali corrosion resistance, and achieve high production efficiency, high production efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

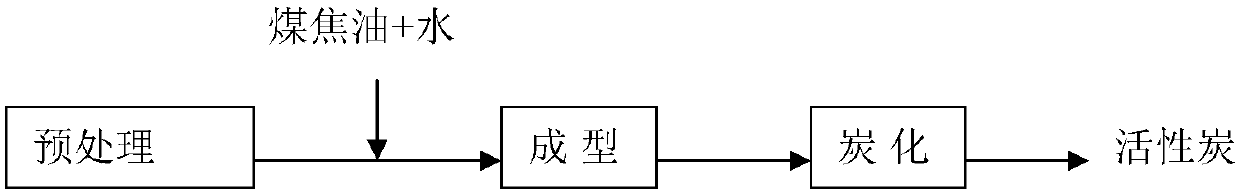

Method used

Image

Examples

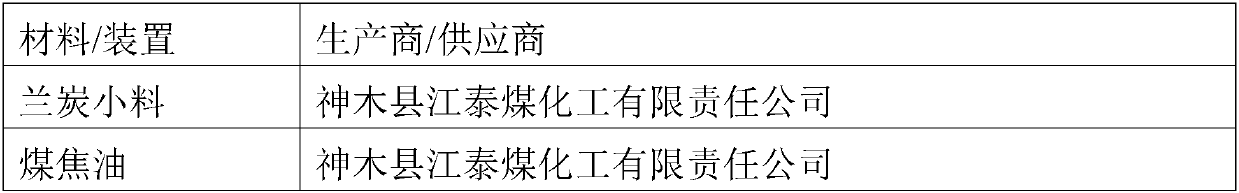

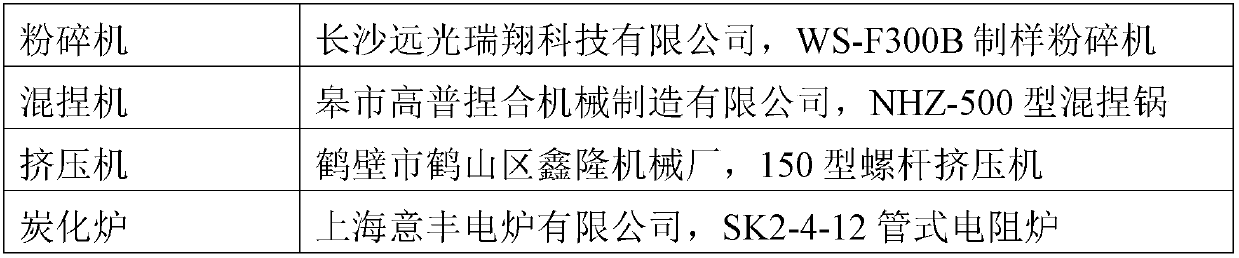

preparation example Construction

[0040] The method for preparing activated carbon according to the present invention has at least the following three advantages: (1) there are fewer types of raw materials and relatively low prices, semi-carbon small materials, coal tar and water; (2) the process is simple and the production cycle is short; (3) The requirements for the device are relatively low, and no special corrosion-resistant device is required. The method of the invention can improve the production efficiency of the activated carbon, reduce the production cost, increase the added value of the product of the coking plant, prolong the industrial chain and improve the economic benefit.

[0041] In another aspect, the invention provides activated carbon obtained according to the method of the invention. The activated carbon obtained according to the method of the invention exhibits a very high adsorption and mechanical strength. Preferably, the activated carbon of the present invention has a particle strengt...

Embodiment 1

[0054] The semi-coke small material is crushed with a pulverizer until 95% of the particles pass through a 100-mesh sieve. According to the weight ratio of semi-coke small material: coal tar: water of 62:28:10, coal tar and water are added to the broken semi-coke small material. Knead the mixture evenly in the kneading pot for at least 20 minutes, and the kneading temperature is 30-50°C. Use an extruder to make the material into strips with a diameter of about 3mm. In a carbonization furnace, at a temperature of 150-200°C, pre-oxidize with air for 90 minutes, and then carbonize at 850°C for 2 hours. After cooling, activated carbon is obtained. The performance of the prepared activated carbon product is as follows:

[0055] Granular strength (%) 96.3

[0056] Iodine adsorption value (mg / g) 836.29

Embodiment 2

[0058] The semi-coke small material is crushed with a pulverizer until 95% of the particles pass through a 100-mesh sieve. According to the weight ratio of semi-coke small material: coal tar: water of 62:28:10, coal tar and water are added to the broken semi-coke small material. Knead the mixture evenly in the kneading pot for at least 20 minutes, and the kneading temperature is 30-50°C. Use an extruder to make the material into strips with a diameter of about 3mm. In the carbonization furnace, the temperature is 150-200°C, the air is pre-oxidized for 90 minutes, and then carbonized at 850°C for 2.5 hours. After cooling, activated carbon is obtained. The performance of the prepared activated carbon product is as follows:

[0059] Granular strength (%) 97.6

[0060] Iodine adsorption value (mg / g) 907.54

PUM

| Property | Measurement | Unit |

|---|---|---|

| Iodine adsorption value | aaaaa | aaaaa |

| Iodine adsorption value | aaaaa | aaaaa |

| Iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com