V2O5-Sb2(SO4)3/TiO2 low-temperature SCR (selective catalytic reduction) denitration catalyst and preparation method thereof

A denitration catalyst, v2o5-sb2 technology, applied in the field of denitration catalysts, can solve the problem of reducing denitration activity, and achieve the effects of inhibiting the conversion of SO2 to SO3, good selectivity, excellent low-temperature sulfur resistance and reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

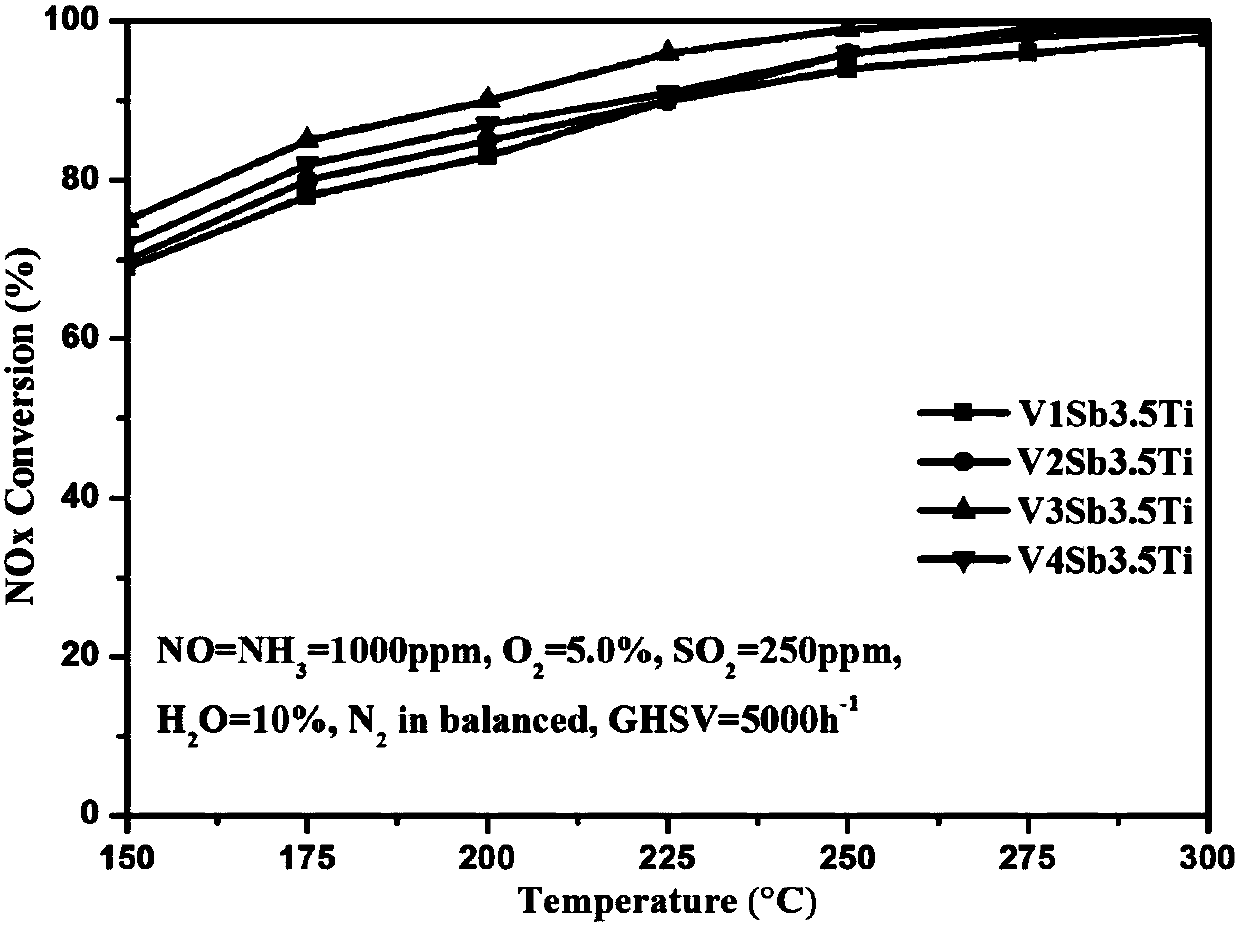

Embodiment 1

[0046] a V 2 o 5 -Sb 2 (SO 4 ) 3 / TiO 2 Low-temperature SCR denitration catalyst, the content of each component of the denitration catalyst is as follows:

[0047] active ingredient V 2 o 5 1wt%;

[0048] Auxiliary Sb 2 (SO 4 ) 3 1wt%;

[0049] Carrier TiO 2 98wt%.

[0050] above V 2 o 5 -Sb 2 (SO 4 ) 3 / TiO 2 The preparation method of low-temperature SCR denitration catalyst comprises the following steps:

[0051] 1) Sb 2 (SO 4 ) 3 / TiO 2 Preparation of powder: Dissolve 1.46kg of antimony lactate in water, add 98kg of titanium dioxide, stir and add 2mol / L dilute sulfuric acid to the solution dropwise, the molar ratio of antimony lactate to dilute sulfuric acid is n 乳酸锑 :n 稀硫酸 The ratio is 1:2; after standing for 6 hours, suction filtration is obtained to obtain a precipitate; the precipitate is dried at 100°C for 36 hours to obtain Sb 2 (SO 4 ) 3 / TiO 2 Powder;

[0052] 2) Preparation of active liquid: Dissolve monoethanolammonium in water, ad...

Embodiment 2

[0058] a V 2 o 5 -Sb 2 (SO 4 ) 3 / TiO 2 Low-temperature SCR denitration catalyst, the content of each component of the denitration catalyst is as follows:

[0059] active ingredient V 2 o 5 5wt%;

[0060] Auxiliary Sb 2 (SO 4 ) 3 5wt%;

[0061] Carrier TiO 2 90wt%.

[0062] above V 2 o 5 -Sb 2 (SO 4 ) 3 / TiO 2 The preparation method of low-temperature SCR denitration catalyst comprises the following steps:

[0063] 1) Sb 2 (SO 4 ) 3 / TiO 2 Preparation of powder: Dissolve 7.32kg of antimony lactate in water, add 90kg of titanium dioxide, stir and add 1mol / L dilute sulfuric acid to the solution dropwise, the molar ratio of antimony lactate to dilute sulfuric acid is n 乳酸锑 :n 稀硫酸 The ratio is 1:3; after standing for 10 hours, suction filtration is obtained to obtain a precipitate; the precipitate is dried at 140°C for 12 hours to obtain Sb 2 (SO 4 ) 3 / TiO 2 Powder;

[0064] 2) Preparation of active liquid: Dissolve monoethanolammonium in water, a...

Embodiment 3

[0070] a V 2 o 5 -Sb 2 (SO 4 ) 3 / TiO 2 Low-temperature SCR denitration catalyst, the content of each component of the denitration catalyst is as follows:

[0071] active ingredient V 2 o 5 3wt%;

[0072] Auxiliary Sb 2 (SO 4 ) 3 3wt%;

[0073] Carrier TiO 2 94wt%.

[0074] above V 2 o 5 -Sb 2 (SO 4 ) 3 / TiO 2 The preparation method of low-temperature SCR denitration catalyst comprises the following steps:

[0075] 1) Sb 2 (SO 4 ) 3 / TiO 2 Preparation of powder: Dissolve 4.38kg of antimony lactate in water, add 94kg of titanium dioxide, stir and add 1.5mol / L dilute sulfuric acid to the solution dropwise, the molar ratio of antimony lactate to dilute sulfuric acid is n 乳酸锑 :n 稀硫酸 The ratio is 1:4; after standing for 7 hours, suction filtration is obtained to obtain a precipitate; the precipitate is dried at 110°C for 18 hours to obtain Sb 2 (SO 4 ) 3 / TiO 2 Powder;

[0076] 2) Preparation of active liquid: Dissolve monoethanolammonium in water, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com