Preparation method of silicon dioxide-coated carbon fiber material, product and application

A carbon fiber material, silicon dioxide technology, applied in the field of lithium ion batteries, can solve the problems of poor cycle stability, material crushing and falling off, specific capacity drop too fast, etc., to achieve the effect of improving electrical conductivity, low cost and easy to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

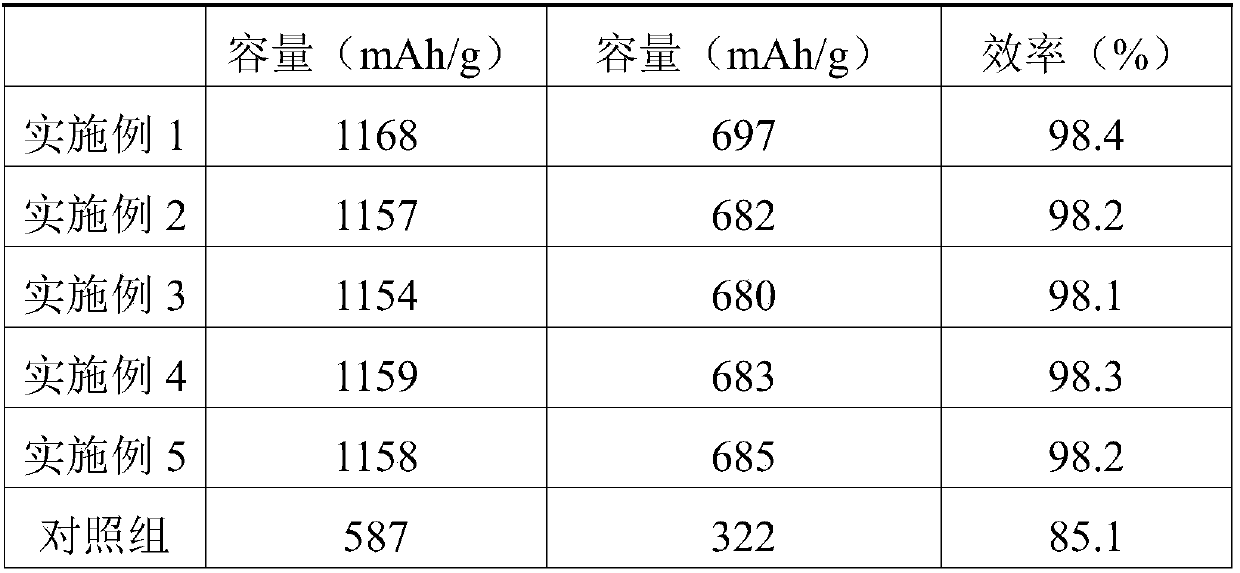

Examples

Embodiment 1

[0035] A preparation method of a silica-coated carbon fiber material:

[0036] (1) Evenly disperse 100g of kapok fiber in 300g of acetone, then add 120g of toluene diisocyanate, 1g of stannous octoate T-9 and 20g of aminopropyltriethoxysilane in sequence, and continue stirring for 2 hours at 50°C ;

[0037] (2) After the above-mentioned reaction solution is cooled to room temperature, wash, filter and separate 2 times with acetone in the above-mentioned step (1), and obtain the pretreated kapok fiber after the filtrate is dried;

[0038] (3) Mix ethyl orthosilicate with anhydrous ethanol solution, and heat to 10-60°C for use; prepare an ethyl orthosilicate solution with a concentration of 12mM;

[0039] (4) Submerge the pretreated kapok fibers in the tetraethyl orthosilicate solution, keep the liquid level higher than the upper surface of the kapok fibers, and let stand for deposition for 30min;

[0040] (5) After the kapok fibers after deposition are rinsed with ethanol sol...

Embodiment 2

[0043] A preparation method of a silica-coated carbon fiber material:

[0044](1) Evenly disperse 100g of loofah fiber in 100g of toluene, then add 40g of toluene diisocyanate and 10g of aminopropyltrimethoxysilane in sequence, and continue to stir and react at 40°C for 1h;

[0045] (2) After the above-mentioned reaction solution is cooled to room temperature, wash and filter the isolate 2 times with toluene in the above-mentioned step (1), and obtain the pretreated loofah fiber after the filter is dried;

[0046] (3) Mix ethyl orthosilicate with anhydrous ethanol solution, and heat to 10-60° C. for use; prepare an ethyl orthosilicate solution with a concentration of 10 mM;

[0047] (4) Immerse the pretreated loofah fiber in the tetraethyl orthosilicate solution, keep the liquid level higher than the upper surface of the loofah fiber, and let it stand for 30 minutes;

[0048] (5) After the deposited loofah fiber was rinsed with ethanol solution and deionized water for 4 times...

Embodiment 3

[0051] A preparation method of a silica-coated carbon fiber material:

[0052] (1) Evenly disperse 100g of bamboo fiber in 500g of N,N-dimethylformamide, then add 300g of toluene diisocyanate, 3g of dibutyltin dilaurate T-12 and 30g of N-aminoethyl-3-ammonia Propylmethyldimethoxysilane, continuously stirred and reacted for 3h at 60°C;

[0053] (2) After cooling the above reaction solution to room temperature, wash and filter the isolate 3 times with N,N-dimethylformamide in the above step (1), and obtain the pretreated bamboo fiber after the filter is dried;

[0054] (3) Mix ethyl orthosilicate with anhydrous ethanol solution, and heat it to 10-60°C for use; prepare an ethyl orthosilicate solution with a concentration of 15mM;

[0055] (4) immerse the pretreated bamboo fiber in the tetraethyl orthosilicate solution, keep the liquid level higher than the upper surface of the bamboo fiber, and let it stand for deposition for 30min;

[0056] (5) after the bamboo fiber after dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com