Graphene-containing heat-dissipating coating and preparation method thereof

A heat-dissipating coating and graphene technology, applied in the field of coatings, can solve the problems of low infrared radiation rate, poor heat transfer performance, poor heat dissipation, etc., achieve high heat transfer performance, good heat transfer performance, and increase the space infrared radiation area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

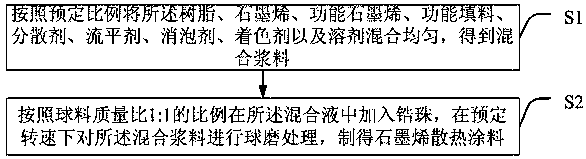

[0033] Based on above-mentioned graphene heat-dissipating coating, the present invention also provides a kind of preparation method of graphene heat-dissipating coating, wherein, as figure 1 shown, including the following steps:

[0034] S1. Mix the resin, graphene, functional filler, dispersant, leveling agent, colorant and solvent uniformly according to a predetermined ratio to obtain a mixed slurry;

[0035] S2. Add zirconium beads to the mixed slurry according to the mass ratio of the ball to material at a ratio of 1:1, and perform ball milling on the mixed slurry at a predetermined speed in a planetary sand mill to obtain a graphene heat-dissipating coating. . Preferably, the rotational speed of the ball milling treatment is 40-600 rpm, and the time is 100-150 min.

Embodiment 1

[0038] Graphene heat dissipation coating includes: 6g N-type high-purity graphene (average number of layers 4 layers, sheet diameter 5μm, thickness 2.86nm), 2g functional graphene, 3.5g spherical alumina powder (particle size 50nm), 4g carbon fiber (tube diameter 5-20nm, average tube length 3-15μm), 5.5g of carbon black, 35g of water-based silicone modified acrylic resin, 2g of acrylate polymer dispersant, 1.5g of leveling agent, 12g of amino resin, Propylene glycol methyl ether 2.5g, isobutanol 17g, water 9g.

[0039] The preparation method of described graphene heat dissipation coating comprises the steps:

[0040] 1. Weigh 6g N-type high-purity graphene powder (average number of layers is 4 layers, sheet diameter 5μm, thickness 2.86nm), 2g functional graphene, 3.5g spherical alumina powder (particle size 50nm), 4g carbon fiber (tube diameter 5-20nm, average tube length 3-15μm), 35g silicone acrylic resin, 2g acrylate polymer dispersant, 1.5g leveling agent, 5.5g carbon black...

Embodiment 2

[0046] Graphene heat dissipation coating includes: 4gN-type high-purity graphene (average number of layers 5 layers, sheet diameter 10μm, thickness 3nm), 4g functional graphene, 6g aluminum nitride powder, 1g carbon fiber (tube diameter 5-20nm, average tube length 3-15μm), 2g alumina fiber, 8g orange pearl powder, 48g water-based acrylic resin, 3g dispersant, 2g leveling agent, 0.1g defoamer, 5.9g industrial ethanol, 16g water

[0047] The preparation method of described graphene heat dissipation coating comprises the steps:

[0048] 1. Weigh 4g N-type high-purity graphene (average number of layers is 5 layers, sheet diameter 10μm, thickness 4nm), 4g functional graphene, 5.9g industrial ethanol, 16g water and 2g acrylate polymer dispersant and stir In the dispersion plate; adjust the mixer speed to 1300rpm / min, and the time is 24 hours to obtain the composite graphene dispersion;

[0049] 2. Add 6g aluminum nitride powder (3000 mesh), 1g carbon fiber (diameter 5-20nm, average...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com