A method for preparing catalytic oil slurry-based solid carbon spheres and a new chemical deposition system

A chemical deposition, catalytic oil technology, applied in chemical instruments and methods, carbon preparation/purification, chemical/physical processes, etc., can solve the problems of polluting the ecological environment, shortage, economic value is not really released, etc., to achieve dispersion. Good property, high dispersion, overcoming the effect of long preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

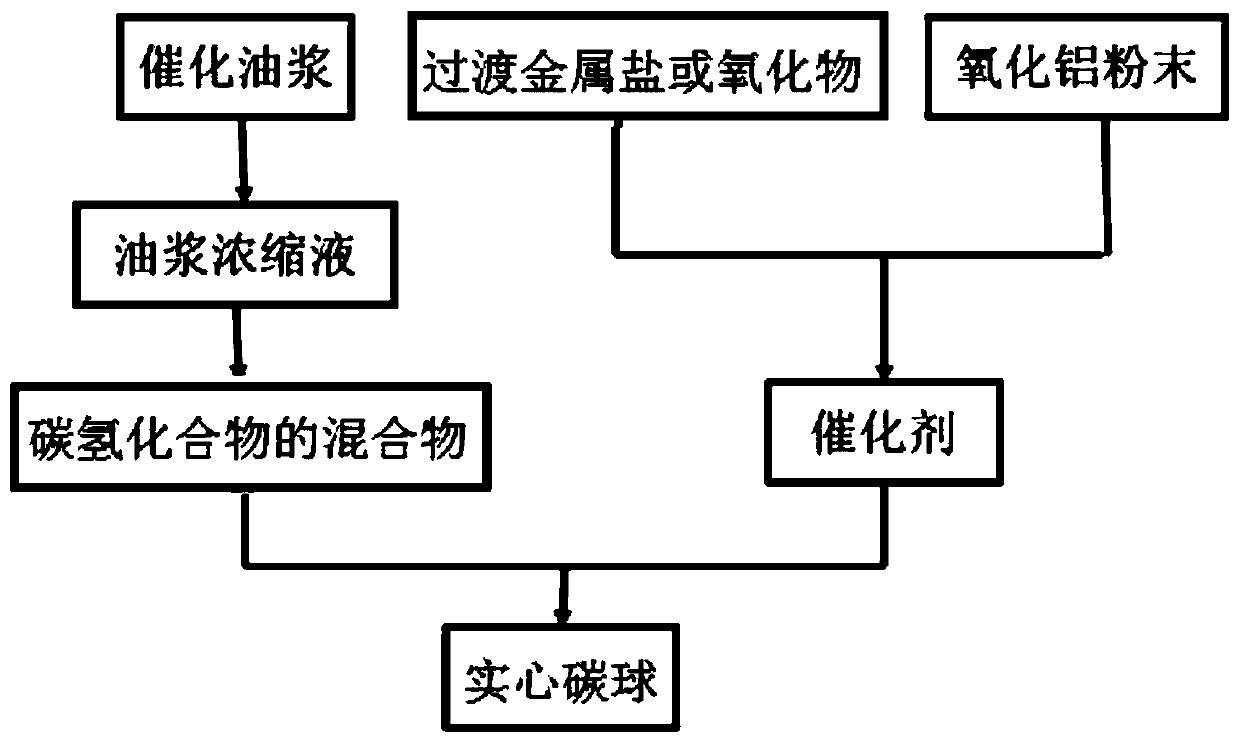

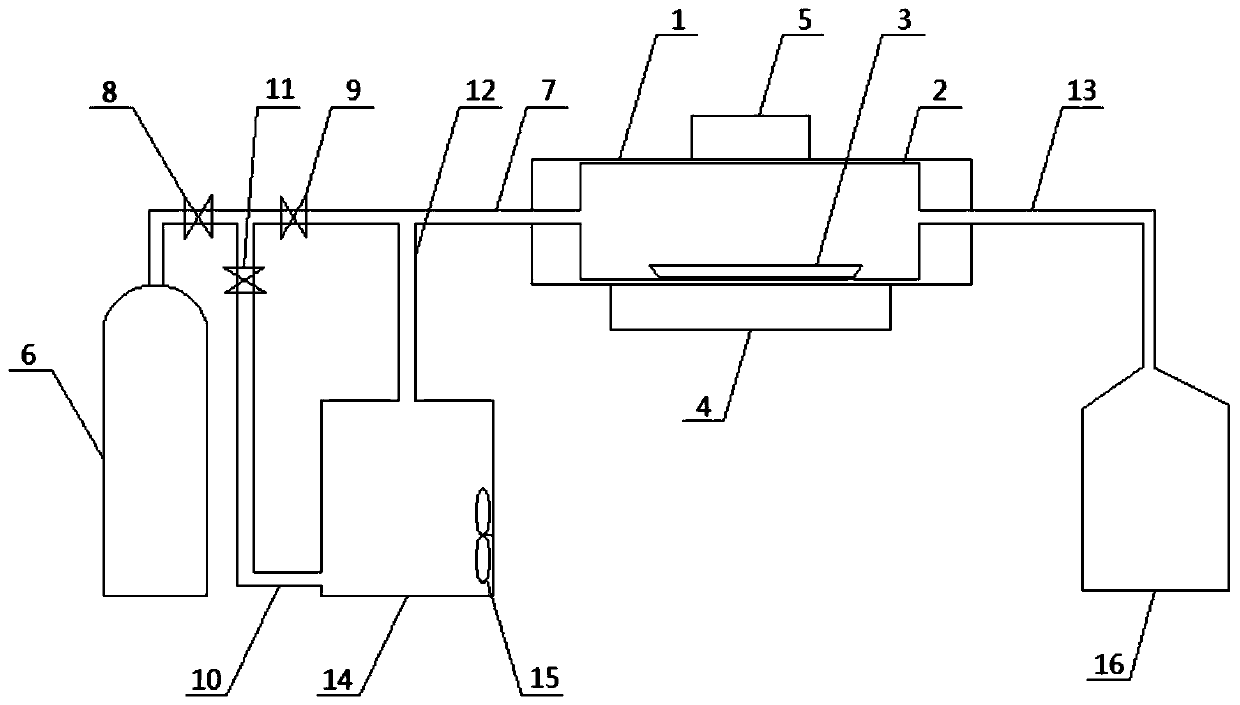

[0042] A method for preparing catalytic oil slurry-based solid carbon spheres is as follows:

[0043] 1. Oil slurry removal: add 200mL heptane to 8g of catalytic oil slurry, reflux at 90°C for 50min, cool for 100min, and use filter paper with a pore size of 1μm to vacuum filter to obtain filtrate a; filter the obtained filter paper and insoluble matter in Dry at 100°C for 80 minutes, add 200mL of toluene and reflux at 110°C for 100 minutes, vacuum filter to obtain filtrate b; mix filtrate a and filtrate b, and then perform rotary evaporation to remove solvent to obtain oil slurry concentrate;

[0044] 2. Reprocessing of the concentrate: After fully dissolving 150g of the oil slurry concentrate obtained in step 1 in 500mL of toluene, slowly add 150mL of concentrated sulfuric acid into it and stir rapidly to make the heavy components reunite, and cool to room temperature after the obtained mixed solution is stable. Use filter paper with a pore size of 0.45 μm for vacuum filtrati...

Embodiment 2

[0058] The difference between this embodiment and embodiment 1 is only: the gas intake rate of argon in step 5 of embodiment 2 is 7cm 3 / min, the particle size of the prepared solid carbon spheres is 1.54-2.12 μm.

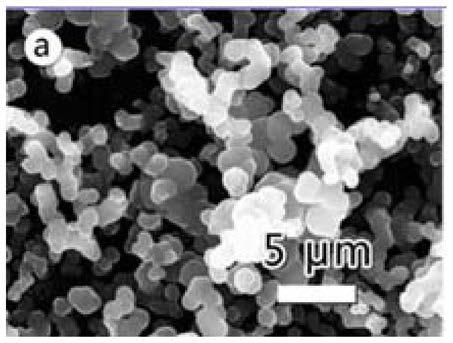

[0059] The particle size and image 3 , Figure 4 It can be seen from the SEM image of the solid carbon spheres that the inert gas intake rate has a greater impact on the particle size of the solid carbon spheres. This is because the greater the intake rate, the more solid carbon sources enter the reaction chamber with the inert gas, and the solid The greater the probability of collision, aggregation and growth between the carbon source particles and the catalyst powder on the porcelain boat, the easier it is to form solid carbon spheres with larger particles. Therefore, the preparation method of the present invention can prepare solid carbon spheres with different particle size requirements by adjusting the intake rate of the inert gas. From image 3 and Fig...

Embodiment 3

[0061] The difference between this example and Example 1 is that the transition metal salt used in preparing the catalyst in Step 3 of Example 3 is ferric nitrate, the mass of ferric nitrate used is 2.0 g, and the particle size of the obtained solid carbon spheres is 0.86-1.65 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com