Lithium battery composite positive electrode material and preparation method thereof, and lithium battery positive electrode

A technology of composite positive electrode material and positive electrode material is applied in the field of lithium battery positive electrode, lithium battery composite positive electrode material and its preparation, and can solve problems such as capacity decrease.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

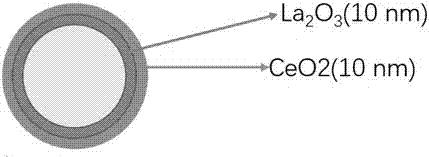

[0022] Lithium battery composite positive electrode material, its preparation method is: a, the positive electrode material particle is placed in the processing chamber of ALD system, and processing chamber is evacuated to the pressure in the range of 0.3 to 0.5mbar during the deposition process, and positive electrode The material particles are kept at a temperature of 100-200°C during the deposition process; b, pulse with deionized water for 0.3S, and carry out the adsorption reaction for 60S, c, then purge excess water with inert gas, d, use three (2 , 2,6,6-tetramethyl-3,5-heptanedione) lanthanum pulse 5S, adsorption reaction 60S, e, purge excess tris(2,2,6,6-tetramethyl- 3,5-heptanedione) lanthanum; f, steps b, c, d, and e are a thermal atomic layer deposition (ALD) cycle, and steps b, c, d, and e are repeated in sequence to realize dilanthanum trioxide in the positive electrode particles The surface of the material grows layer by layer with a thickness of about 10 nm; g,...

Embodiment 2

[0024] Lithium battery composite positive electrode material, its preparation method is: a, the positive electrode material particle is placed in the processing chamber of ALD system, and processing chamber is evacuated to the pressure in the range of 0.3 to 0.5mbar during the deposition process, and positive electrode The material particles are kept at a temperature of 100-200°C during the deposition process; b, pulse with deionized water for 0.5S, and carry out the adsorption reaction for 50S, c, then purge excess water with inert gas, d, use three (2 , 2,6,6-tetramethyl-3,5-heptanedione) lanthanum pulse 5S, adsorption reaction 70S, e, purge excess tris(2,2,6,6-tetramethyl- 3,5-heptanedione) lanthanum; f, steps b, c, d, and e are a thermal atomic layer deposition (ALD) cycle, and steps b, c, d, and e are repeated in sequence to realize dilanthanum trioxide in the positive electrode particles The layer-by-layer growth thickness of the material surface is about 15nm; g, pulse ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com