High-efficiency all-optical-fiber column vector light beam laser

A beam laser, high-efficiency technology, applied in the direction of lasers, laser components, phonon exciters, etc., can solve the problem of difficult to achieve high-efficiency all-fiber column vector laser output, increase experimental complexity and uncertainty, and difficult to achieve the ultimate Optimal output coupling ratio and other issues to achieve high mode conversion efficiency, high laser slope efficiency, and low insertion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

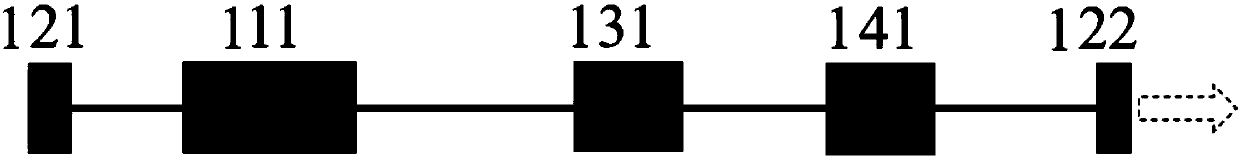

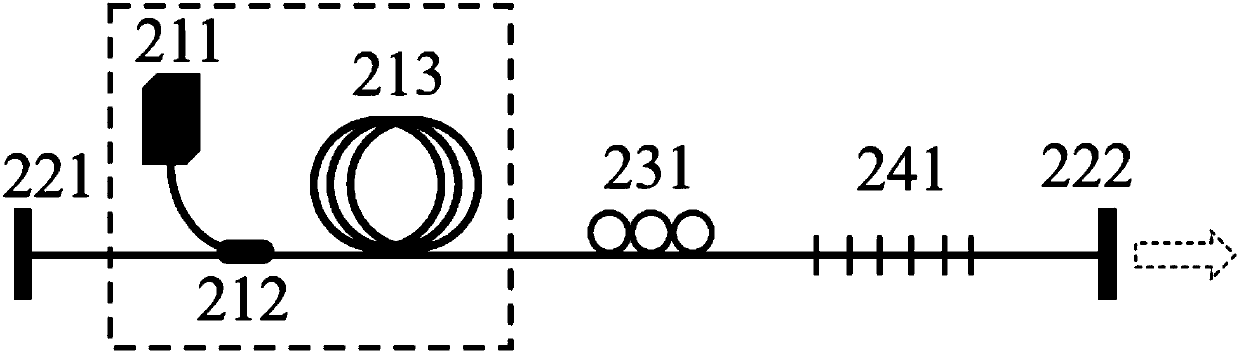

[0021] Before describing the structure of the embodiment in detail, a brief description of the theory of few-mode long-period fiber gratings will be given.

[0022] Few-mode long-period fiber gratings are used in few-mode fibers using ultraviolet laser technology, femtosecond laser technology, arc technology, mechanical microbend technology, CO 2 The resonant wavelength of the few-mode long-period fiber grating is within the emission spectrum range of the doped fiber and within the reflection wavelength range of the two reflective surfaces. The few-mode fiber refers to the fiber whose normalized frequency V is greater than 2.405 and can support few-mode or multi-mode transmission. Because TM 01 and TE 01 The mode belongs to the first-order mode, so we generally take 2.40501 and TE 01 mode, and can avoid interference caused by higher-order modes. Similar to the long-period grating written in a single-mode fiber, when the resonance condition is satisfied, the incident fundam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com