Environmentally protective puffed feed for penaeus vannamei and preparation method thereof

A technology for extruded feed and white shrimp, which is applied in the direction of animal feed, animal feed, and animal feed molding or processing, can solve the problems of nutrient component destruction, inability to meet nutritional needs, etc. Improve the effect of the formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

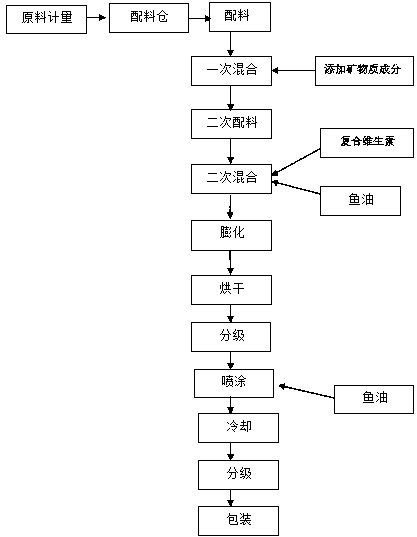

Method used

Image

Examples

Embodiment 1

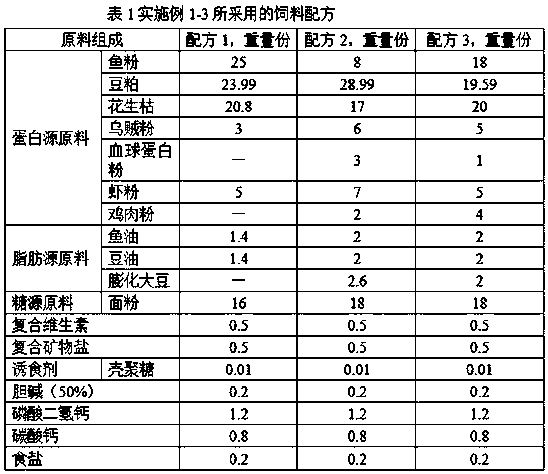

[0028] Example 1 With the raw material components listed in the formula 1 in Table 1, the preparation method of the present invention is used to prepare the extruded pellet feed for Penaeus vannamei, and the specific steps are as follows:

[0029] (1) Weighing the protein source raw materials, fat source raw materials, sugar source raw materials, multivitamins, multimineral salts, food attractants, and water in the parts by weight;

[0030] (2) Grind protein source raw materials, sugar source raw materials, and compound mineral salts for 1-2 times respectively, pass through a 60-mesh sieve to obtain powdery raw materials, mix and stir evenly, and then add fat source raw materials and multivitamins while stirring to prepare Feed base material;

[0031] (3) Input the prepared feed base material into the single-shaft extrusion extruder, turn on the pelletizing motor, and turn the pelletizing frequency converter from "min" to "max", and adjust it to 25-45 , the screw speed is 200...

Embodiment 2

[0035] Example 2 With the raw material components listed in the formula 2 in Table 1, the preparation steps described in Example 1 were used to prepare the extruded pellet feed for Penaeus vannamei; at the same time, the same feed formula was used and implemented according to the The ring die pellet feed preparation method that example 1 adopts makes ring die pellet feed.

[0036] The prepared extruded pellet feed and ring die pellet feed were used to control culture of Penaeus vannamei (divided into extruded pellet feed group and ring die pellet feed group): in a low temperature environment of 13-27°C, 0.40g of South American 80 days for white prawns. After the control breeding, the survival rate SR (%) and the feed coefficient (FCR) of the shrimp in the extruded pellet feed group and the ring die pellet feed group were measured.

[0037] After measurement, in this embodiment, the feed coefficient of the extruded pellet feed group is 1.08, and the survival rate is 79.0%; the...

Embodiment 3

[0038] Example 3 With the raw material components listed in the formula 3 in Table 1, the above-mentioned preparation steps of Example 1 were used to prepare the extruded pellet feed for Penaeus vannamei; at the same time, the same feed formula was used, according to the example 1. The ring die pellet feed preparation method adopted to prepare the ring die pellet feed.

[0039] The prepared extruded pellet feed and ring die pellet feed were used to control culture of Penaeus vannamei (divided into extruded pellet feed group and ring die pellet feed group): in a low temperature environment of 13-27°C, 0.40g of South American 80 days for white prawns. After the control breeding, the survival rate SR (%) and the feed coefficient (FCR) of the shrimp in the extruded pellet feed group and the ring die pellet feed group were measured.

[0040] After measurement, in the present embodiment, the feed coefficient of the extruded pellet feed group is 1.1, and the survival rate is 78.7%; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com