High-performance anticorrosive coating with graphene and preparation method of anticorrosive coating

An anti-corrosion coating and graphene technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of poor oxidation resistance and easy agglomeration of graphene, achieve excellent corrosion resistance, and solve the effect of easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

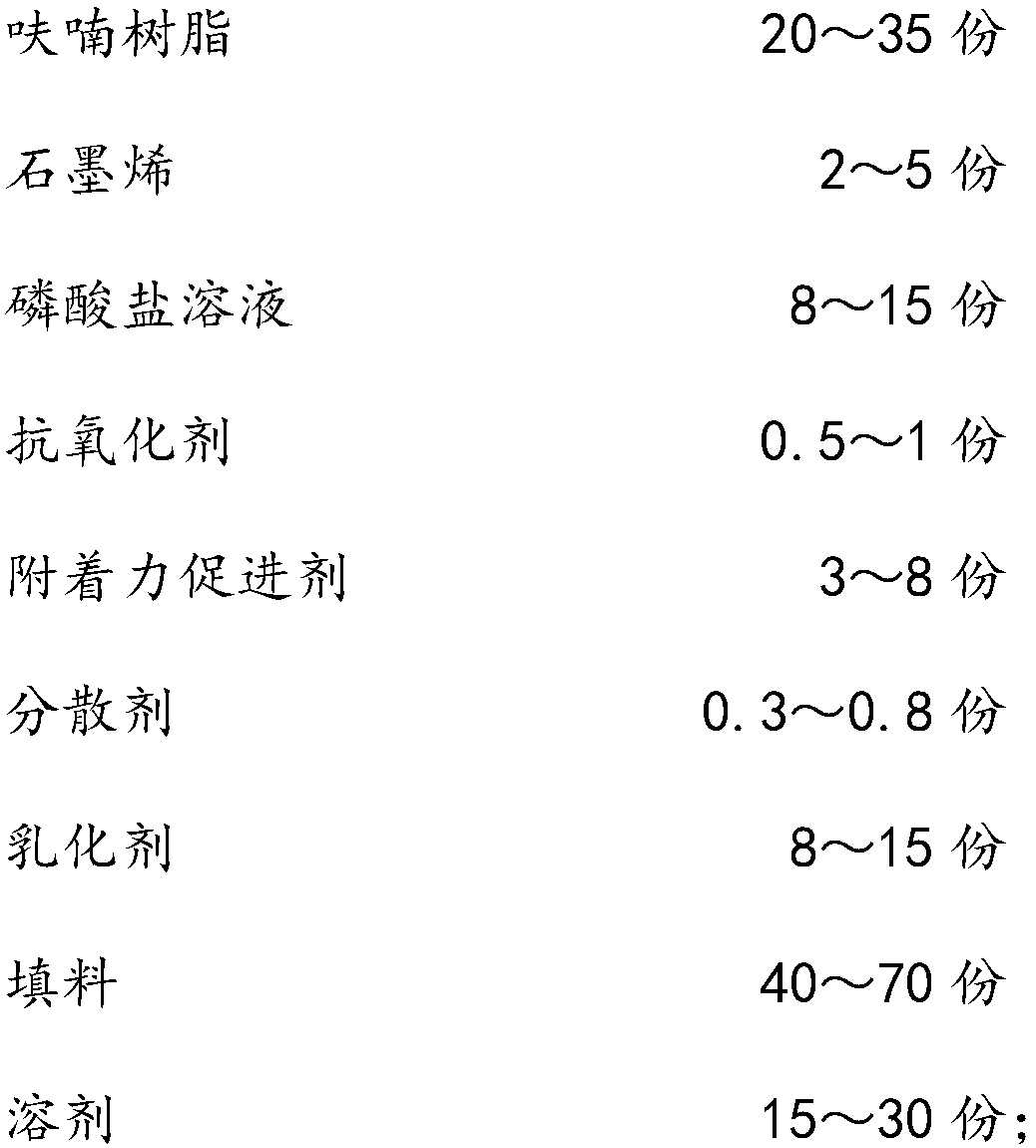

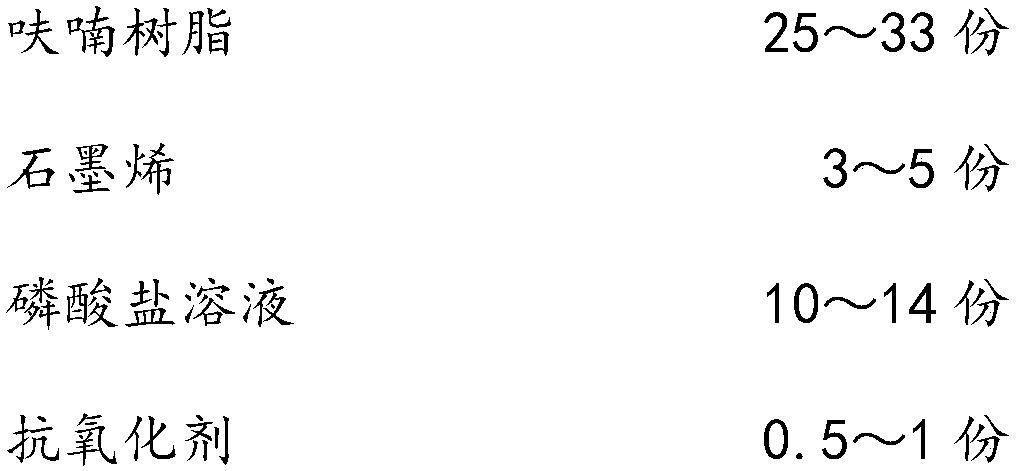

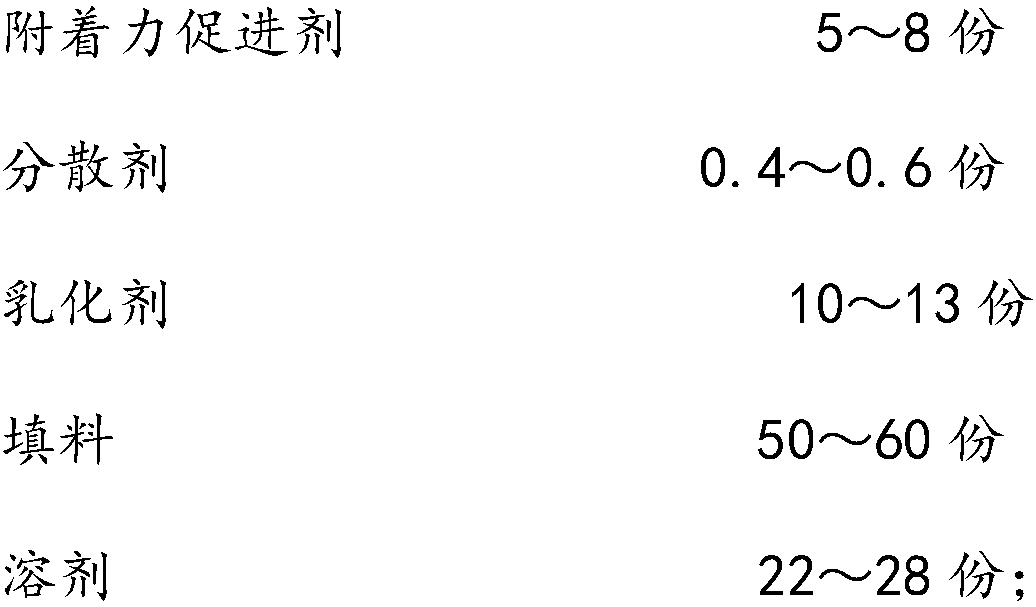

Method used

Image

Examples

Embodiment 1

[0049] Preparation of component A: Heat 3 parts of graphene to 180°C, pour it into 11 parts of phosphate solution, evaporate and remove water at 160°C, then heat-preserve at 190°C for 12 minutes to prepare modified graphene; Put 26 parts of furan resin, modified graphene, and 23 parts of solvent in a container and stir, then add 0.7 part of antioxidant, 0.4 part of dispersant, 10 parts of emulsifier, and 5 parts of adhesion promoter, at a speed of 1500r / min Stir and mix for 35 minutes; add 50 parts of filler, and stir and mix for 30 minutes at a speed of 3000r / min to obtain the component A;

[0050] Preparation of component B: uniformly mix 15 parts of sulfonic acid curing agent and 12 parts of methanol aqueous solution in a container to obtain the component B.

Embodiment 2

[0052] Preparation of component A: Heat 4 parts of graphene to 180°C, pour it into 12 parts of phosphate solution, evaporate and remove water at 160°C, then heat-preserve at 190°C for 12 minutes to prepare modified graphene; Put 28 parts of furan resin, modified graphene, and 25 parts of solvent in a container and stir, then add 0.8 parts of antioxidant, 0.5 parts of dispersant, 11 parts of emulsifier, and 6 parts of adhesion promoter, at a speed of 1500r / min Stir and mix for 35 minutes; add 55 parts of filler, and stir and mix for 30 minutes at a speed of 3000r / min to obtain the component A;

[0053] Preparation of component B: uniformly mix 16 parts of sulfonic acid curing agent and 13 parts of methanol aqueous solution in a container to obtain the component B.

Embodiment 3

[0055] Preparation of component A: heat 5 parts of graphene to 180°C, pour it into 13 parts of phosphate solution, evaporate and remove water at 160°C, then heat-preserve at 190°C for 12 minutes to prepare modified graphene; Put 31 parts of furan resin, modified graphene, and 27 parts of solvent in a container and stir, then add 0.9 parts of antioxidant, 0.6 parts of dispersant, 12 parts of emulsifier, and 7 parts of adhesion promoter, at a speed of 1500r / min Stir and mix for 35 minutes; add 60 parts of filler, and stir and mix for 30 minutes at a speed of 3000r / min to obtain the component A;

[0056] Preparation of component B: uniformly mix 17 parts of sulfonic acid curing agent and 14 parts of methanol aqueous solution in a container to obtain the component B.

[0057] When in use, mix components A and B according to the mass ratio of 4.3:1, and then paint and use after mixing evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com