Surface-hydroxylation mesoporous SiO2-TiO compound self-cleaning coating layer and preparation method thereof

A self-cleaning coating and hydroxylated mesoporous technology, which can be used in coatings, antifouling/underwater coatings, paints containing biocides, etc., can solve the problems of limited active sites and constraints on the application prospects of TiO's hydrophilic properties. Achieve the effects of low preparation cost, high bonding strength and gripping force, and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A surface hydroxylated mesoporous SiO provided by the invention 2 -TiO 2 The steps of the preparation method of the composite self-cleaning coating are as follows:

[0029] Step 1: Dissolve 0.06-0.08g of CTAB colloidal particles in a mixed solution of 32-37mL deionized water and 14-16mL of absolute ethanol, add 0.5-2.0mL tetraethyl orthosilicate to the above-mentioned mixed solution and dissolve it with 100-300r / min speed stirring for 10~30min to prepare SiO 2 Sol;

[0030] Step 2: Add 10-12mL tetrabutyl titanate to a mixed solution of 0.9-1.1mL acetylacetone and 34-36mL absolute ethanol to prepare TiO 2 Sol;

[0031] Step 3: Place the clean and dry substrate on the SiO prepared in step 1 2sol, and stand at 60-70°C for 19-21 hours to obtain a layer of SiO attached to the surface 2 sol substrate and calcined it at 530-580°C for 3-3.5 hours to remove CTAB, and what is attached to the surface of the substrate after calcination is the prepared mesoporous SiO 2 thin ...

Embodiment 2

[0037] A surface hydroxylated mesoporous SiO provided by the invention 2 -TiO 2 The steps of the preparation method of the composite self-cleaning coating are as follows:

[0038] Step 1: Dissolve 0.06-0.08g of CTAB colloidal particles in a mixed solution of 32-37mL deionized water and 14-16mL of absolute ethanol, add 0.5-2.0mL tetraethyl orthosilicate to the above-mentioned mixed solution and dissolve it with 100-300r / min Stirring speed and stir for 10-30min to prepare SiO 2 Sol;

[0039] Step 2: Add 10-12mL tetrabutyl titanate to a mixed solution of 0.9-1.1mL acetylacetone and 34-36mL absolute ethanol, add 1-2 drops of dilute hydrochloric acid to the mixed solution and stir evenly to obtain TiO 2 Sol;

[0040] Step 3: Put the clean and dry quartz glass as the substrate on the SiO prepared in step 1 2 sol, and stand at 60-70°C for 19-21 hours to obtain a layer of SiO attached to the surface 2 sol quartz glass substrate and calcined it at 530-580°C for 3-3.5 hours to re...

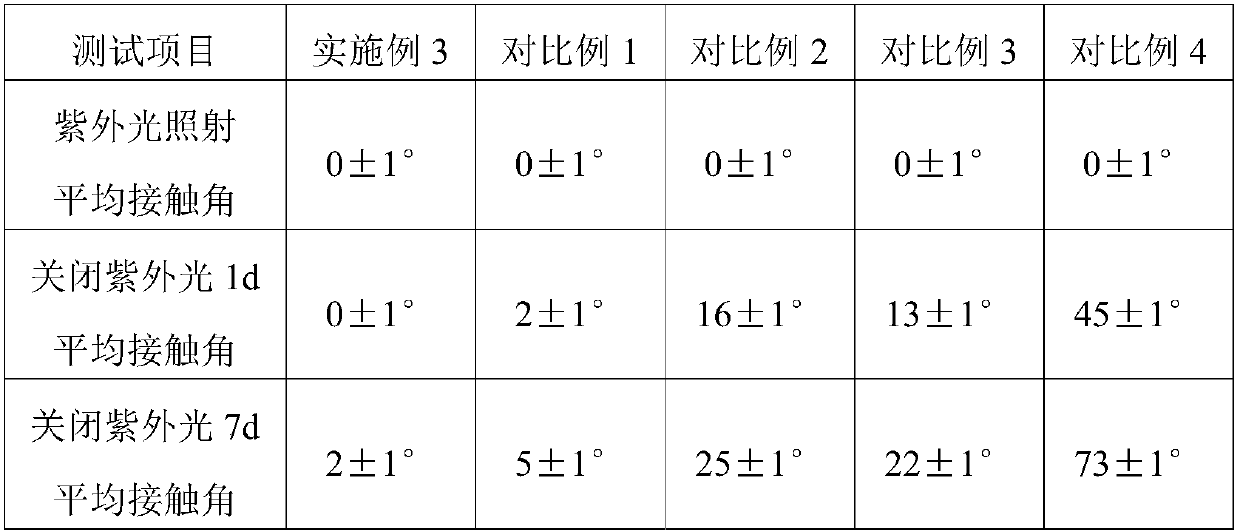

Embodiment 3

[0046] A surface hydroxylated mesoporous SiO provided by the invention 2 -TiO 2 The steps of the preparation method of the composite self-cleaning coating are as follows:

[0047] Step 1: Dissolve 0.08g of CTAB colloidal particles in a mixed solution of 35mL deionized water and 15mL absolute ethanol, add 1.5mL tetraethyl orthosilicate to the above mixed solution and stir at a stirring speed of 200r / min for 20min to prepare SiO 2 Sol;

[0048] Step 2: Add 10mL tetrabutyl titanate to a mixed solution of 1mL acetylacetone and 35mL absolute ethanol to prepare TiO 2 Sol;

[0049] Step 3: Put the clean and dry quartz glass as the substrate on the SiO prepared in step 1 2 sol, and stood at 60°C for 20h to obtain a layer of SiO attached to the surface 2 sol quartz glass substrate and calcined it at 550°C for 3h to remove CTAB, the mesoporous SiO2 adhered to the surface of the quartz glass substrate after calcination 2 thin film, the mesoporous SiO 2 The film thickness is 0.5μm;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com