Perilla leaf oil and application thereof

A technology of perilla leaf oil and perilla aldehyde, applied in the field of medicine, can solve the problems of unreliable uniform standard of perilla leaf oil, complex component distribution, etc., and achieve the effects of low toxicity and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: the preparation method of perilla leaf oil

[0049] 1) Weighing: Weigh 10kg perilla leaves and set aside;

[0050] 2) Distillation: Put the perilla leaves into the cleaned extraction tank, distill with water steam, keep the steam pressure at 0.1MPa, start timing from the drop of oil, distill for 3-5 hours, and the temperature is 100-120°C;

[0051] 3) Oil collection: after the steam is condensed, the distillate is collected, the dregs are discarded, and the distillate is allowed to stand for 20 minutes to obtain a water layer, a volatile oil layer, and an emulsified layer. The volatile oil layer is separated, and the water layer is discarded. Put it into a separatory funnel and continue to stand; the emulsified layer was left to stand for 12 hours, the water layer was discarded, and the volatile oil layers were combined to obtain perilla leaf oil (yield: 0.5%).

experiment example 1

[0052] Experimental Example 1: Content Detection

[0053] According to the method of embodiment 1, perilla leaf of Hunan Hanshou County, Hunan Taoyuan County, Hunan Dingcheng, Jiangsu Lianyungang, Chaozhou, Henan Nanyang, Guangxi Yulin, Anguo Shifo Town, Chongqing Fuling, Shandong Yantai and other places Carry out processing, extract and prepare the perilla leaf oil that obtains and detect, and specific detection method is:

[0054] 1. Preparation of the test solution: Take about 0.1g of perilla leaf oil, weigh it accurately, put it in a 10ml measuring bottle, add n-hexane to dilute to the mark, shake well, filter, and take the filtrate to get final product.

[0055] 2. Preparation of reference substance solution: Take an appropriate amount of perillaldehyde reference substance, weigh it accurately, add n-hexane to make a solution containing 4mg of perillaldehyde per 1ml, and obtain it.

[0056] 3. GC / MS analysis method:

[0057] Chromatographic conditions: chromatographic c...

experiment example 2

[0068] Experimental example 2: detection of moisture

[0069] 1. The detection method is Karl Fischer non-aqueous titration method, and the determination procedure is as follows:

[0070] (1) Calibration: Calibrate with 20 microliters of purified water by weight loss method, repeat the measurement three times, and only when the RSD of the calibration content of the three times is not greater than 1.0%, can the sample be measured.

[0071] (2) Sample measurement: take 0.1g sample for measurement, repeat the measurement three times for each sample, and when the content RSD of the three times is not more than 1.0%, record the average value of the three measurement values, which is the moisture content (%) of the sample.

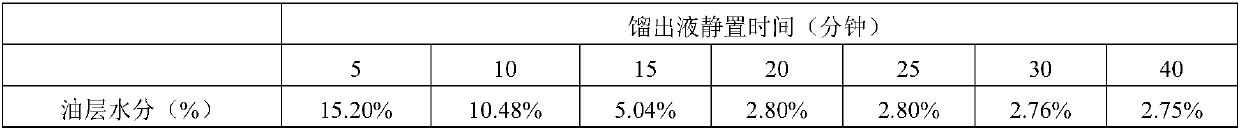

[0072] 2. Test results: see Table 2-1, 2-2, 2-3

[0073] Table 2-1: Effect of secondary steam distillation time on total volatile oil yield

[0074]

[0075] Description: 1. Yield of volatile oil = weight of volatile oil / weight of perilla leaf for extractio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com