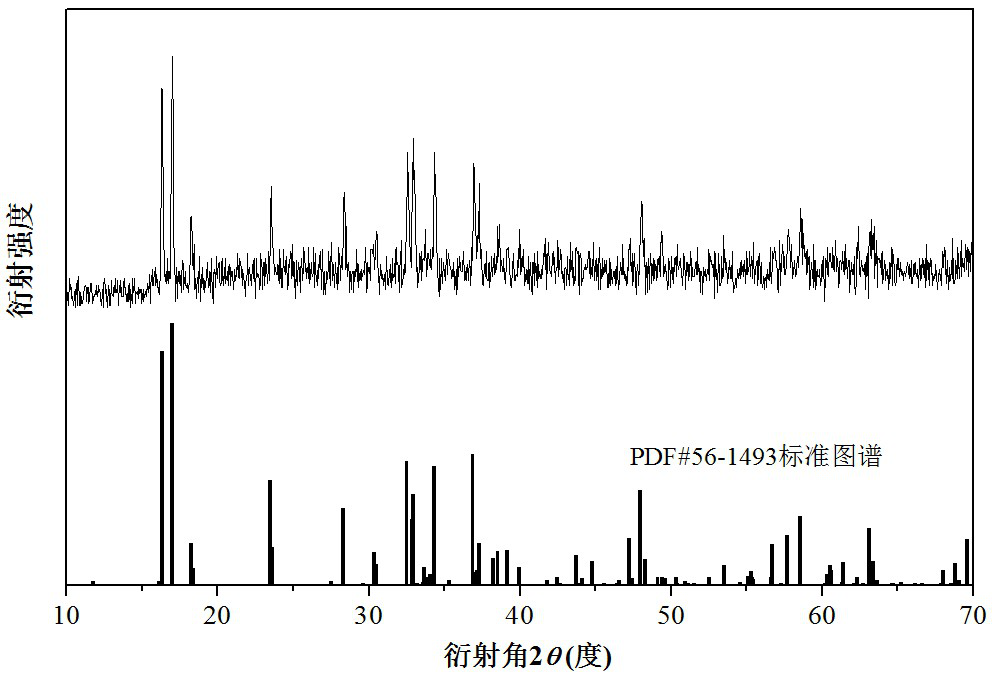

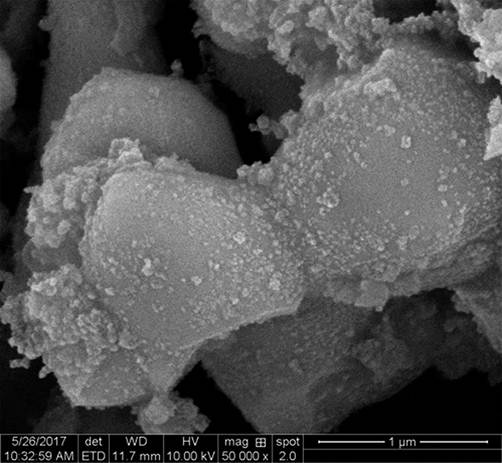

A synergistically modified cobalt lithium fluorophosphate positive electrode material and preparation method thereof

A technology of cobalt lithium fluorophosphate and positive electrode materials, which is applied in nanotechnology for materials and surface science, battery electrodes, nanotechnology, etc., can solve problems such as poor cycle performance and low conductivity, and achieve improved electronic conductivity, Effects of high energy density, excellent rate characteristics and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) LiOH . h 2 O, Co(CH 3 COO) 2 . 4H 2 O, Ni(CH 3 COO) 2 . 4H 2 O, LiF press Li: Co: Ni: the ratio of the amount of F substance is 2.02:0.93:0.07:1 in deionized water and stir evenly, mix H 3 PO 4 , LiF press PO 4 3- : The ratio of the amount of F substance to H is 1:1 3 PO 4 Drop into the above solution, continue to stir for 8 minutes, transfer it to a high-pressure reactor, heat it in water at 200°C for 11 hours, naturally cool to room temperature, take it out, and dry it to obtain the precursor;

[0035] (2) Mix the above-mentioned nickel-doped precursor with the carbon in Ketjen black / ascorbic acid at a mass ratio of 95:5, dry-grind, press into tablets, pre-fire at 350°C for 6 hours in an argon atmosphere, and Cool down, take out and grind, press into tablets, and calcined at 650°C for 5 h to obtain Li 2 co 0.93 Ni 0.07 PO 4 F / C material;

[0036] (3) Weigh 0.5 g of silica powder into a beaker, add ionized water, ultrasonicate for 30 min, then ad...

Embodiment 2

[0038] (1) LiOH . h 2 O, Co(NO 3 ) 2 . 6H 2 O, Ni(NO 3 ) 2 . 6H 2 O and LiF are stirred in deionized water evenly according to the ratio of Li: Co: Ni: F substance amount of 2.02:0.93:0.07:1, and NH 4 h 2 PO 4 , LiF press PO 4 3- : NH in the amount ratio of F substance to 1:1 4 h 2 PO 4 Add it into the above solution, continue to stir for 15 min, transfer it to a high-pressure reactor, heat it in water at 180°C for 15 h, cool it down to room temperature naturally, take it out, and dry it to obtain the precursor;

[0039] (2) After mixing the above-mentioned nickel-doped precursor and the carbon in glucose / sucrose at a mass ratio of 90:10, add an appropriate amount of ethanol, wet mill, dry at 60°C, grind, and press into tablets. Under an argon atmosphere, Precalcined at 400°C for 4 h, quenched the sample in water, ground, pressed into tablets, and calcined at 700°C for 4 h to obtain Li 2 co 0.93 Ni 0.07 PO 4 F / C material;

[0040] (3) Weigh 1.0 g pH=8.5 na...

Embodiment 3

[0042] (1) LiCH 3 COO . 2H 2 O. CoSO 4 . 7H 2 O, NiSO 4 . 6H 2 O and HF are stirred evenly in deionized water according to the ratio of Li: Co: Ni: F substance amount of 2.02:0.93:0.07:1, and NH 4 h 2 PO 4 , LiF press PO 4 3- : NH in the amount ratio of F substance to 1:1 4 h 2 PO 4 Add it into the above solution, continue to stir for 20 min, transfer it to a high-pressure reactor, heat it in water at 120°C for 20 h, cool it down to room temperature naturally, take it out, and dry it to obtain the precursor;

[0043] (2) Mix the above-mentioned nickel-doped precursor with the carbon in carbon nanofibers / pyrrole at a mass ratio of 85:15, dry-grind, press into tablets, and pre-calcine at 300 °C for 7 h in an argon atmosphere, continuously Calcined at 600°C for 5 h to obtain Li 2 co 0.93 Ni 0.07 PO 4 F / C material;

[0044] (3) Weigh 1.0 g of silica particles into a beaker, add ionized water, ultrasonicate for 90 min, then add 1.0 g of the above Li 2 co 0.93 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com