Thermal treatment method of die-casting aluminum alloy and die-casting aluminum alloy material

A heat treatment method and casting aluminum alloy technology, which is applied in the field of die-casting aluminum alloy materials and heat treatment of die-casting aluminum alloys, can solve problems such as high-temperature deformation of die-casting parts, uncontrolled gas content, and entrainment of castings, so as to avoid high-temperature deformation, Effects in simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

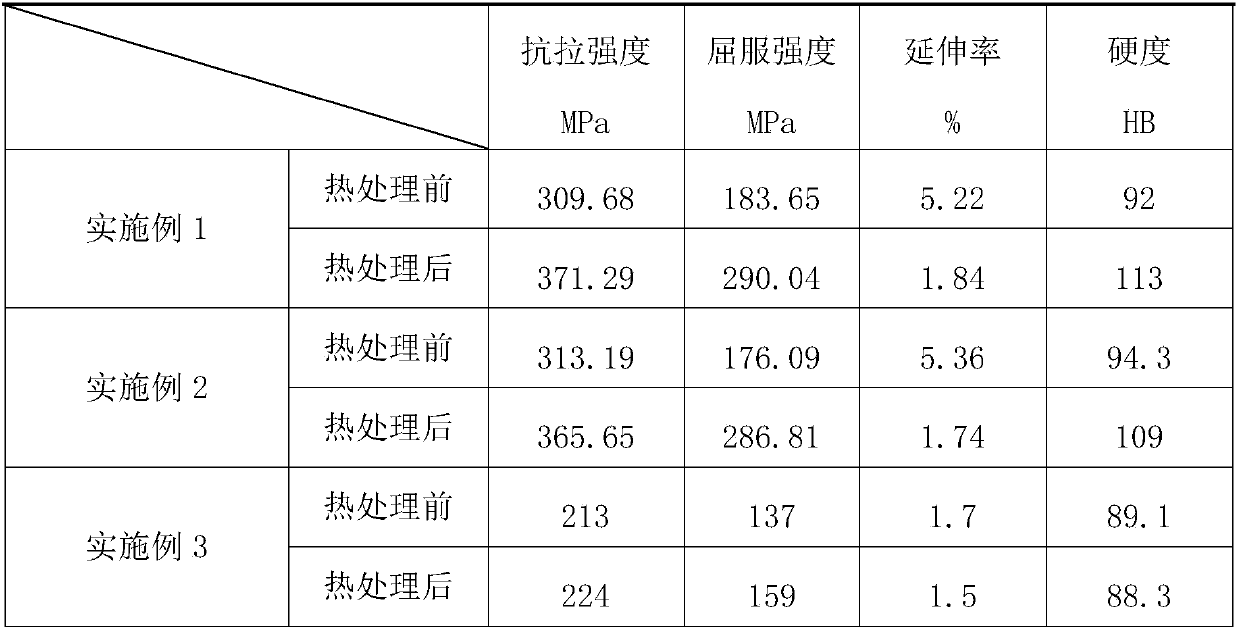

Embodiment 1

[0034] Raw material ratio

[0035] Calculated by weight percentage: silicon, content 8.05%; iron, content 0.319%; copper, content 0.527%; manganese, content 0.0824%; magnesium, content 1.062%, zinc 0.157% content; titanium, content 0.186%; tin, the content is ≤0.00055%; lead, the content is ≤0.0003%; cadmium, the content is ≤0.0021%; the balance is aluminum.

[0036] Preparation Process

[0037] (1) Put 90% of the total amount of silicon and aluminum ingots into the melting furnace, and then heat up.

[0038] (2) After heating and making it completely melted, stir more than 3 times. The stirring is helpful for the alloying and homogenization of the material, and the stirring is not less than 5 minutes each time. The stirring head is made of graphite material, and low-speed mechanical stirring is carried out.

[0039] (3) After the temperature reaches 830-850° C., add titanium element additives, iron element additives and copper element additives, and stir again to homogeniz...

Embodiment 2

[0048] Raw material ratio

[0049] Calculated by weight percentage: silicon, content 7.98%; iron, content 0.321%; copper, content 0.606%; manganese, content 0.0828%; magnesium, content 1.123%, zinc, content 0.156%; titanium, content 0.187%; tin, the content is ≤0.00013%; lead, the content is ≤0.0003%; cadmium, the content is ≤0.0021%; the balance is aluminum.

[0050] Preparation Process

[0051] (1) Put 90% of the total amount of silicon and aluminum ingots into the melting furnace, and then heat up.

[0052] (2) After heating and making it completely melted, stir more than 3 times. The stirring is helpful for the alloying and homogenization of the material, and the stirring is not less than 5 minutes each time. The stirring head is made of graphite material, and low-speed mechanical stirring is carried out.

[0053] (3) After the temperature reaches 830-850° C., add titanium element additives, iron element additives and copper element additives, and stir again to homogeni...

Embodiment 3

[0062] The Japanese ADC12 is heat treated. The heat treatment process is as follows: place the ADC12 aluminum alloy die casting in a heat treatment furnace, start from 25°C at a near-uniform heating rate of about 8°C / min, heat it up to 160°C and keep it warm. Continue for 420 minutes, then remove the sample and air cool. A heat-treated die-cast aluminum alloy is obtained. The main chemical composition standards of ADC12 are: copper (Cu) 1.5-3.5, silicon (Si) 9.6-12.0, magnesium (Mg) ≤ 0.3, zinc (Zn) ≤ 1.0, iron (Fe) ≤ 1.3, manganese (Mn) ≤ 0.5, tin (Sn) ≤ 0.3, lead (Pb) ≤ 0.1, cadmium (Cd) ≤ 0.005, and the balance is aluminum (Al).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com