Curing agent for compounding heavy metal pollution soil as well as preparation method and application method thereof

A technology of heavy metal polluted soil and its application method, which is applied in the fields of environmental engineering, civil engineering, and environmental geotechnical engineering, can solve the problems of serious pollution, high cost, and large energy consumption, and achieve good durability, enhanced stability, and reduced contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The steel slag powder of the above curing agent is prepared by the following method: crush the water-quenched converter and pass through a 2mm sieve, place the sieved steel slag powder in an oven, and dry it by airflow at a temperature of 100-150°C to make it The water content is lower than 2%, then ground and passed through a 200-mesh sieve, and then calcined in an electric furnace at 500-700°C for 1-2 hours to obtain steel slag powder.

[0033] The potassium dihydrogen phosphate powder of the above-mentioned curing agent is prepared by the following method: put the industrial-grade potassium dihydrogen phosphate in an oven, and dry it by airflow at a temperature of 100-150°C to make the moisture content lower than 2%, and grind And pass through a 0.075mm sieve to obtain potassium dihydrogen phosphate powder.

[0034] The preparation method of the curing agent for the restoration of heavy metal-contaminated sites includes the following steps:

[0035] 1) Mix lime powd...

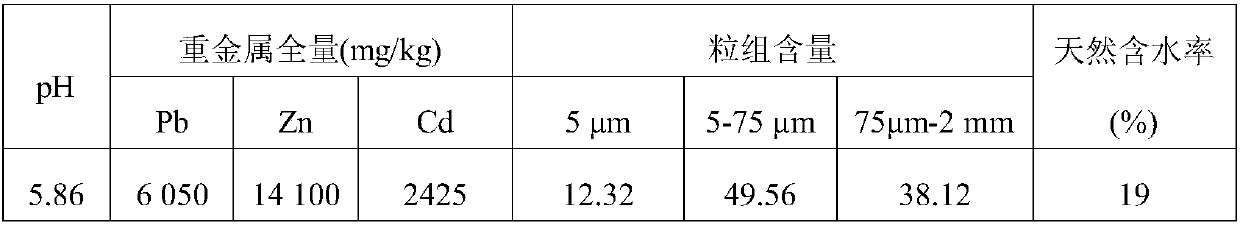

Embodiment 1

[0057] Mix and stir the prepared curing agent with the composite heavy metal-contaminated soil sample in test material 1), wherein the dosage of the curing agent is 5% (accounting for the dry weight of the composite metal-contaminated soil), and the moisture content of the prepared sample is controlled at 20 ± 2 %, after stirring evenly, adopt the static pressure method to prepare a columnar sample with a diameter of 5cm and a height of 10cm, wrap it tightly with a fresh-keeping bag, and preserve it for 28 days at 20°C and humidity >95%.

Embodiment 2

[0059] Same as the sample preparation process and curing process of embodiment 1, difference is, the dosage of curing agent is 10% (curing agent accounts for heavy metal and organic matter compound polluted soil dry weight).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com