Natural tea oil mask and preparation method thereof

A natural technology of camellia oil surface, applied in the direction of pharmaceutical formulations, cosmetic preparations, dressing preparations, etc., can solve the problems of tea oil flammability and volatility, poor medium dispersion, unfavorable absorption, etc., to increase cell water content, Good stability and the effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

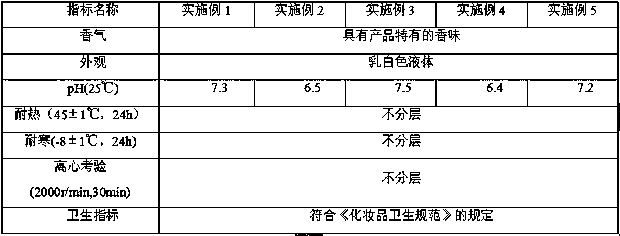

Examples

Embodiment 1

[0027] Refined camellia oil activation: take 30 parts of refined camellia oil and place it in a high-speed shearing machine for high-speed shear activation. The shear activation speed is 1650r / min, and the activation time is 9min;

[0028] Preparation of activated water: Take 50 parts of deionized water and put it into the electro-hydraulic pulse device for activation. The voltage used is 55kv, the action time is 3min, and the operation is repeated twice;

[0029] Put the activated and refined camellia oil into the reactor, slowly stir and add 0.6 parts of tea saponin into the reactor, and raise the temperature in the reactor to 70°C;

[0030] Take 8 parts of Yuzhu extract, 10 parts of black fungus polysaccharide, 6 parts of aloe vera gel, 7 parts of blueberry anthocyanin, 1 part of peppermint extract, 2.5 parts of clove extract, 5 parts of passion fruit seed oil, 2 parts of elm leaf essential oil , added to the reaction kettle, stirred and reacted for 30min;

[0031] Take th...

Embodiment 2

[0035] Refined camellia oil activation: take 20 parts of refined camellia oil and place it in a high-speed shearing machine for high-speed shear activation, the shear activation speed is 1500r / min, and the activation time is 10min;

[0036] Preparation of activated water: Take 55 parts of deionized water and put it into the electro-hydraulic pulse device for activation. The voltage used is 50kv, the action time is 2.5min, and the operation is repeated twice;

[0037] Put the activated and refined camellia oil into the reactor, slowly stir and add 0.6 parts of tea saponin into the reactor, and raise the temperature in the reactor to 72°C;

[0038] Take 5 parts of Yuzhu extract, 6 parts of black fungus polysaccharide, 8 parts of aloe vera gel, 6 parts of blueberry anthocyanin, 3 parts of peppermint extract, 1 part of clove extract, 6 parts of passion fruit seed oil, 1.2 parts of elm leaf essential oil , added to the reaction kettle, stirred and reacted for 20min;

[0039] Take ...

Embodiment 3

[0043] Activation of refined camellia oil: take 23 parts of refined camellia oil and place them in a high-speed shearing machine for high-speed shear activation, the shear activation speed is 1800r / min, and the activation time is 8min;

[0044] Preparation of activated water: Take 48 parts of deionized water and put it into the electro-hydraulic pulse device for activation. The voltage used is 60kv, the action time is 2min, and the operation is repeated twice;

[0045] Put the activated and refined camellia oil into the reactor, slowly stir and add 0.5 parts of tea saponin into the reactor, and raise the temperature in the reactor to 80°C;

[0046] Take 4 parts of Yuzhu extract, 5 parts of black fungus polysaccharide, 7 parts of aloe vera gel, 10 parts of blueberry anthocyanin, 2 parts of peppermint extract, 3 parts of clove extract, 7 parts of passion fruit seed oil, 1.5 parts of elm leaf essential oil , added to the reaction kettle, stirred and reacted for 28min;

[0047] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com