High-frequency magnetic field auxiliary ball-milling preparation method of catalyst for sewage treatment

A high-frequency magnetic field and sewage treatment technology, applied in the field of powder metallurgy, can solve the problems of high efficiency, economy, environmental protection, low absorption and precipitation efficiency, and high cost of adsorbents, and achieve the effects of short preparation time, easy control, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

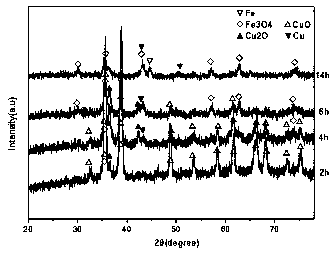

[0043] Example 1. A method for preparing a catalyst for sewage treatment by high-frequency magnetic field-assisted ball milling, which is prepared according to the following steps:

[0044] a. Weigh 4 grams of copper oxide and 5.6 grams of iron powder, mix them evenly and add them to the ball mill jar, add 1 kilogram of grinding balls and 500ml of distilled water;

[0045] b. The stirring rod in the ball milling tank is stirred to drive the grinding balls in the ball milling tank to roll, and finally the mechanochemical action on the powder particles is realized through the impact and friction of the balls on the powder in the ball milling tank;

[0046] c. At the same time, apply a high-frequency magnetic field with a frequency of 20KHz around the ball mill jar to radiate the powder and solution inside the ball mill jar, start high-frequency magnetic field-assisted ball milling, and take out the solution in the ball mill jar after 14 hours of high-frequency assisted ball millin...

Embodiment 2

[0050] Example 2. A method for preparing a catalyst for sewage treatment by high-frequency magnetic field-assisted ball milling, which is prepared according to the following steps:

[0051] a. Weigh 4 grams of copper oxide, 5.6 grams of iron powder, and 0.6 grams of graphite powder, mix them evenly and add them to a ball mill jar, add 1 kilogram of grinding balls, and 500 ml of distilled water.

[0052] b. The stirring rod in the ball milling tank is stirred to drive the grinding balls in the ball milling tank to roll, and finally the mechanochemical action on the powder particles is realized through the impact and friction of the balls on the powder in the ball milling tank;

[0053] c. At the same time, apply a high-frequency magnetic field with a frequency of 20KHz around the ball mill jar to radiate the powder and solution inside the ball mill jar, start high-frequency magnetic field-assisted ball milling, and take out the solution in the ball mill jar after 15 hours of hi...

Embodiment 3

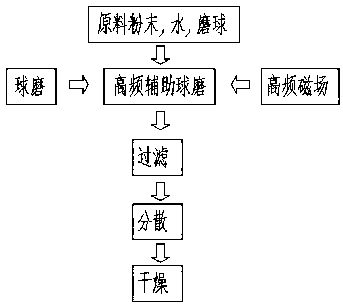

[0056] Example 3. A high-frequency magnetic field-assisted ball milling preparation method of a catalyst for sewage treatment, such as figure 1 Shown, according to the following steps to prepare:

[0057] a. Add the raw material powder into the ball milling jar, and add water into the ball milling jar to obtain product A, then grind the balls in the ball milling jar;

[0058] b. Agitate the grinding balls to crush product A, apply a high-frequency magnetic field to product A, perform high-frequency auxiliary ball milling, take out the mixed solution after 5 to 20 hours, and obtain product B; through the rolling of the balls, the raw material powder is ground , impact, tear, squeeze, stretch, thereby activating the raw material powder; apply a high-frequency magnetic field to realize the radiation of the powder and solution inside the ball mill tank;

[0059] c. Filtrate product B to obtain viscous solid, namely product C;

[0060] d. Add ethanol to product C and put it int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com