Tris(2,4,6-trimethoxyphenyl)phosphine based ionic liquid catalyst and preparation method thereof

A trimethoxyphenyl, ionic liquid technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc. Difficult to recycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh 5mmol (2.66g) of tris(2,4,6-trimethoxyphenyl)phosphine and dissolve it in 100ml of toluene, add 1.2 times molar amount (6mmol, 0.73g) of 1,3-propane sultone dropwise, React in a water-bath stirring reactor at 60°C for 12h; after the reaction, suction filter, wash and dry the product in a drying oven at 60°C for 6h to obtain the ylide; dissolve 2mmol (1.31g) of the ylide in 60ml of anhydrous Add an equimolar amount (2mmol, 0.20g) of concentrated sulfuric acid dropwise to ethanol, stir and react at 60°C for 12h, then evaporate the solvent by rotary evaporation, wash and dry at 60°C for 12h to obtain an ionic liquid catalyst.

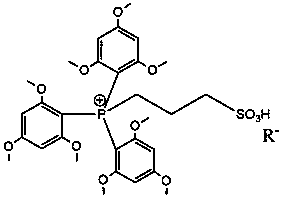

[0022] The structural formula of the ionic liquid catalyst is:

[0023]

[0024] Catalyst activity test comprises the following steps:

[0025] Add methanol and palm oil to the autoclave at an alcohol-to-oil molar ratio of 12:1, and then add a tris(2,4,6-trimethoxyphenyl)phosphine-based ionic liquid catalyst, the amount of catalyst added i...

Embodiment 2

[0027] Weigh 5mmol (2.66g) of tris(2,4,6-trimethoxyphenyl)phosphine and dissolve it in 100ml of N-methylpyrrolidone, add 1.5 times molar amount (7.5mmol, 0.92g) of 1,3-propanesulfonate dropwise Acid lactone, react in a water-bath stirred reactor at 60°C for 10h; after the reaction, filter, wash and dry the product in a drying oven at 60°C for 6h to obtain the ylide; dissolve 2mmol (1.31g) of the ylide In 60ml of absolute ethanol, an equimolar amount (2mmol, 0.39g) of p-toluenesulfonic acid was added dropwise, stirred and reacted at 60°C for 12h, the solvent was removed by rotary evaporation, washed and dried at 60°C for 12h to obtain an ionic liquid catalyst.

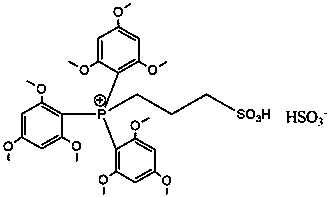

[0028] The structural formula of the ionic liquid catalyst is:

[0029] .

[0030] Catalyst activity test comprises the following steps:

[0031] Add propanol and tung oil to the autoclave at an alcohol-to-oil molar ratio of 20:1, then add a tris(2,4,6-trimethoxyphenyl)phosphine ionic liquid catalyst, the amount of ...

Embodiment 3

[0033] Weigh 5mmol (2.66g) of tris(2,4,6-trimethoxyphenyl)phosphine and dissolve it in 100ml of N-methylpyrrolidone, add 2.0 times molar amount (10.0mmol, 1.22g) of 1,3-propanesulfonate dropwise Acid lactone, react in a water-bath stirred reactor at 130°C for 8h; after the reaction, filter, wash and dry the product in a drying oven (60°C) for 6h to obtain the ylide; 2mmol (1.31g) ylide Dissolve the salt in 60ml of absolute ethanol, add an equimolar amount (2mmol, 0.30g) of trifluoromethanesulfonic acid dropwise, stir and react at 55°C for 12h, then evaporate the solvent by rotary evaporation, wash and dry (60°C) for 12h to obtain an ionic liquid catalyst.

[0034] The structural formula of the ionic liquid catalyst is:

[0035] .

[0036] Catalyst activity test comprises the following steps:

[0037]Add ethanol and soybean oil to the autoclave at an alcohol-to-oil molar ratio of 24:1, and then add tris(2,4,6-trimethoxyphenyl)phosphine ionic liquid catalyst, the amount of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com