Small-bore artificial blood vessel with micropatterned inner wall

An artificial blood vessel and micro-patterning technology, applied in coatings, medical science, prostheses, etc., can solve the problems of inability to guide the oriented growth of endothelial cells, poor mechanical properties of small-caliber artificial blood vessels, etc., and solve the problem of poor biocompatibility Poor, solve the effect of insufficient mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

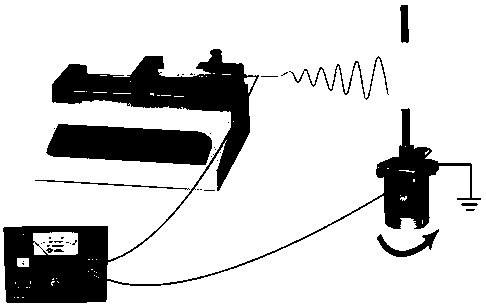

Method used

Image

Examples

example 1

[0027] 1. Cover the AR-P 3250 positive photoresist evenly on the glass sheet with a coater, and after curing at 95°C, use a UV lithography machine to prepare parallel stripe micropatterns with a stripe width and spacing of 20 μm and a depth of 2 μm. Engraving;

[0028] 2. Use a coating machine to evenly cover the surface of the above micropattern photoresist with polydimethylsiloxane, place it on a heating plate at 95°C for 2 hours, and use tweezers to carefully peel off the film on the surface after curing to obtain the micropattern Polydimethylsiloxane film;

[0029] 3. Boil 20 g silkworm silk in 2 L of 0.02 mol / L sodium carbonate deionized aqueous solution for 30 minutes for degumming treatment, wash the boiled silk 6 times with deionized water, loosen it and place it in an oven at 37°C to dry , to obtain degummed silk;

[0030] 4. Dissolve degummed silk in 9.3mol / L lithium bromide aqueous solution at the ratio of 27g:100mL, stir and dissolve in a 60°C oven for 4 hours to...

Embodiment 2

[0039] 1. Soak the micro-patterned small-diameter artificial blood vessel on the inner wall prepared in Example 1 in phosphate buffered saline, and fully wet it to obtain a wet small-caliber artificial blood vessel;

[0040] 2. The wet small-diameter artificial blood vessel is cut into a test sample with a length of 3 cm, and the axial tensile mechanical test is carried out using a Japanese Shimadzu universal material testing machine. min;

[0041] 3. Cut the wet small-diameter artificial blood vessel into a test sample with a length of 6 mm, use the above-mentioned material testing machine to carry out a radial tensile mechanical test, select a load cell with a measuring range of 100 N, and set the tensile rate to 3 mm / min;

[0042] 4. The wet small-caliber artificial blood vessel is cut into a test sample with a length of 2 cm, and the suture strength mechanical test is carried out using the above-mentioned material testing machine and 6-0 polyglycolic acid surgical suture w...

example 3

[0046] 1. Cut the micropatterned small-diameter artificial blood vessel on the inner wall prepared in Example 1 into a test sample with a length of 1 cm, soak it in phosphate buffer solution, and sterilize it in an autoclave to obtain a sterile test sample;

[0047] 2. Place the sterility test sample and the utensils used for cell inoculation in an ultra-clean bench, use ultraviolet sterilization for more than 0.5h, move the sterility test sample into a 24-well plate, and place the sterility test sample on the test sample after drying. Inoculation of inner wall 1x10 5 Endothelial cells were cultured in a carbon dioxide incubator for 2 hours after inoculation to make the cells adhere, then added 0.8mL endothelial cell medium, and placed in a carbon dioxide incubator for 3 days;

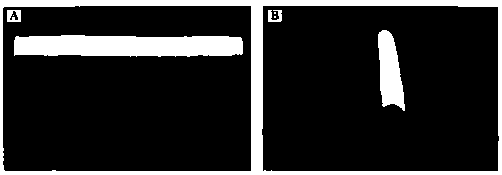

[0048] 3. Immunofluorescent staining of the cultured small-caliber artificial blood vessels, using fluorescein isothiocyanate-labeled phalloidin to stain the cytoskeleton fibrous actin, and then using ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com