A preparation method of self-flame-retardant co-extruded uniaxially stretched microporous diaphragm and microporous diaphragm

A microporous diaphragm, uniaxial stretching technology, applied in structural parts, electrical components, battery pack parts, etc., can solve the problem that the characteristics of polyolefin materials cannot meet the needs of high heat-resistant lithium battery separators, and the heat resistance of the separators No improvement, poor extrusion processing performance, etc., to achieve the effects of good high temperature resistance, uniform pore size distribution, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

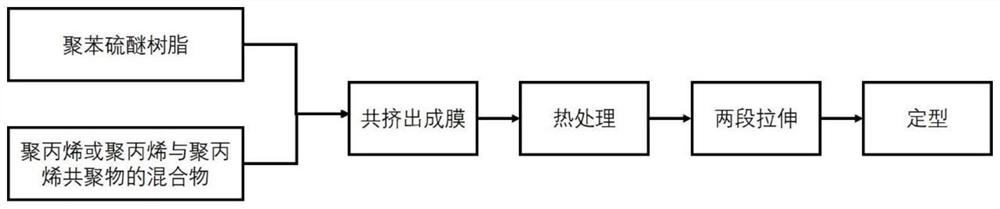

Method used

Image

Examples

Embodiment 1

[0039] Add polyphenylene sulfide with a melt index of 3g / 10min and polypropylene with a melt index of 1g / 10min into different extruders respectively, and co-extrude through a multi-layer die head. The final temperature is 280°C and 230°C respectively, the die head temperature is 290°C, the casting roll temperature is 120°C, the melt draw ratio is 1.5, and three-layer polyphenylene sulfide / polypropylene / polyphenylene sulfide is obtained by casting Ether composite cast film. Heat treatment at 100°C for 8h. One-stage stretching was carried out at 80°C with a stretching rate of 5 mm / min and a stretching ratio of 3%, followed by two-stage stretching at 130°C with a stretching rate of 50 mm / min and a stretching ratio of 100%. The heat-setting temperature is 140°C, the heat-setting time is 3min, and thermal shock is performed in a hot air furnace at 240°C for 5 seconds to obtain a three-layer polyphenylene sulfide / polypropylene / polyphenylene sulfide microporous film. The porosity of...

Embodiment 2

[0041]Add polyphenylene sulfide with a melt index of 12g / 10min, polypropylene with a melt index of 5g / 10min, and random copolymers of propylene and ethylene with a molecular weight of 9000Da and 5% of the mass fraction of polypropylene into different extruders respectively. Layer die head co-extrusion, the end temperature of polyphenylene sulfide layer and polypropylene layer casting machine is 290 ℃ and 260 ℃, the temperature of die head is 290 ℃, the temperature of casting roll is 120 ℃, the melt draw ratio was 20, cast to obtain a three-layer polyphenylene sulfide / polypropylene mixture / polyphenylene sulfide composite cast film. Heat treatment at 150°C for 20h. One-stage stretching was carried out at 80°C with a stretching rate of 50mm / min and a stretching ratio of 20%, followed by two-stage stretching at 140°C with a stretching rate of 150mm / min and a stretching ratio of 110%. The heat-setting temperature is 145°C, the heat-setting time is 4min, and thermal shock is perfor...

Embodiment 3

[0043] Add polyphenylene sulfide with a melt index of 5g / 10min, polypropylene with a melt index of 3g / 10min, and a random copolymer of propylene and butene with a molecular weight of 20% of polypropylene and a molecular weight of 40,000Da into different extruders. Multi-layer die head co-extrusion, the end temperature of polyphenylene sulfide layer and polypropylene layer casting machine are 280 ℃ and 260 ℃ respectively, the temperature of die head is 290 ℃, the temperature of casting roll is 120 ℃, the melt draw The elongation ratio is 4, and a three-layer polyphenylene sulfide / polypropylene mixture / polyphenylene sulfide composite cast film is obtained by casting. Heat treatment at 110°C for 12h. One-stage stretching was performed at 80°C with a stretching rate of 50mm / min and a stretching ratio of 10%, followed by two-stage stretching at 130°C with a stretching rate of 50mm / min and a stretching ratio of 100%. The heat-setting temperature is 140°C, the heat-setting time is 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com