2-system aluminum alloy and smelting and casting method thereof

An aluminum alloy and melting furnace technology, which is applied to 2-series aluminum alloys with Ni content and their smelting and casting, and high Fe fields, can solve the problems of poor heat resistance of 2-series aluminum alloys, and achieves improved grain boundary strength and good degassing effect. , the effect of easy inhalation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Such as figure 1 A smelting and casting method for a 2-series aluminum alloy shown, comprising the steps of:

[0031] A. Ingredients: The mass percentage ratio of each element in the aluminum alloy ingot raw material is as follows:

[0032] element

Si

Fe

Ni

Cu

Mg

Zn

Ti

mn

Cr

Al

content

0.15

1.4

1.4

2.6

1.7

0.1

0.06

0.1

0.1

margin

[0033] Prepare aluminum alloy raw materials according to the above ratio;

[0034] B. Smelting: put the aluminum alloy raw material prepared in step A into a melting furnace for melting. During the melting process, high-purity aluminum ingots, pure zinc ingots, aluminum-copper master alloys, and aluminum-iron master alloys are put into the melting furnace in turn until the charge is melted. Finally, pure magnesium ingots are put in, the melting temperature is 740°C, and the aluminum alloy raw materials in the melting furnace are completely melted and t...

Embodiment 2

[0040] The difference between embodiment 2 and embodiment 1 is that in step A, the mass percentage ratio of each element of the aluminum alloy ingot raw material is as follows:

[0041] element

Embodiment 3

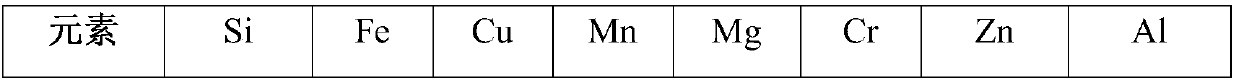

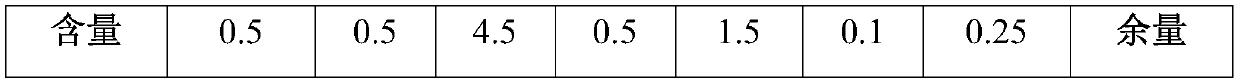

[0043] The difference between embodiment 3 and embodiment 1 is that in step A, the mass percentage ratio of each element of the aluminum alloy ingot raw material is as follows:

[0044] element

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com