Magnetic molecular sieve catalyst doped with transition metal and preparation method and application of magnetic molecular sieve catalyst

A technology of transition metals and transition metal elements, applied in the direction of molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems that hinder the wide-scale application and promotion of molecular sieves, are difficult to separate, limit applications, etc., and achieve good reuse High stability, good stability and uniform shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

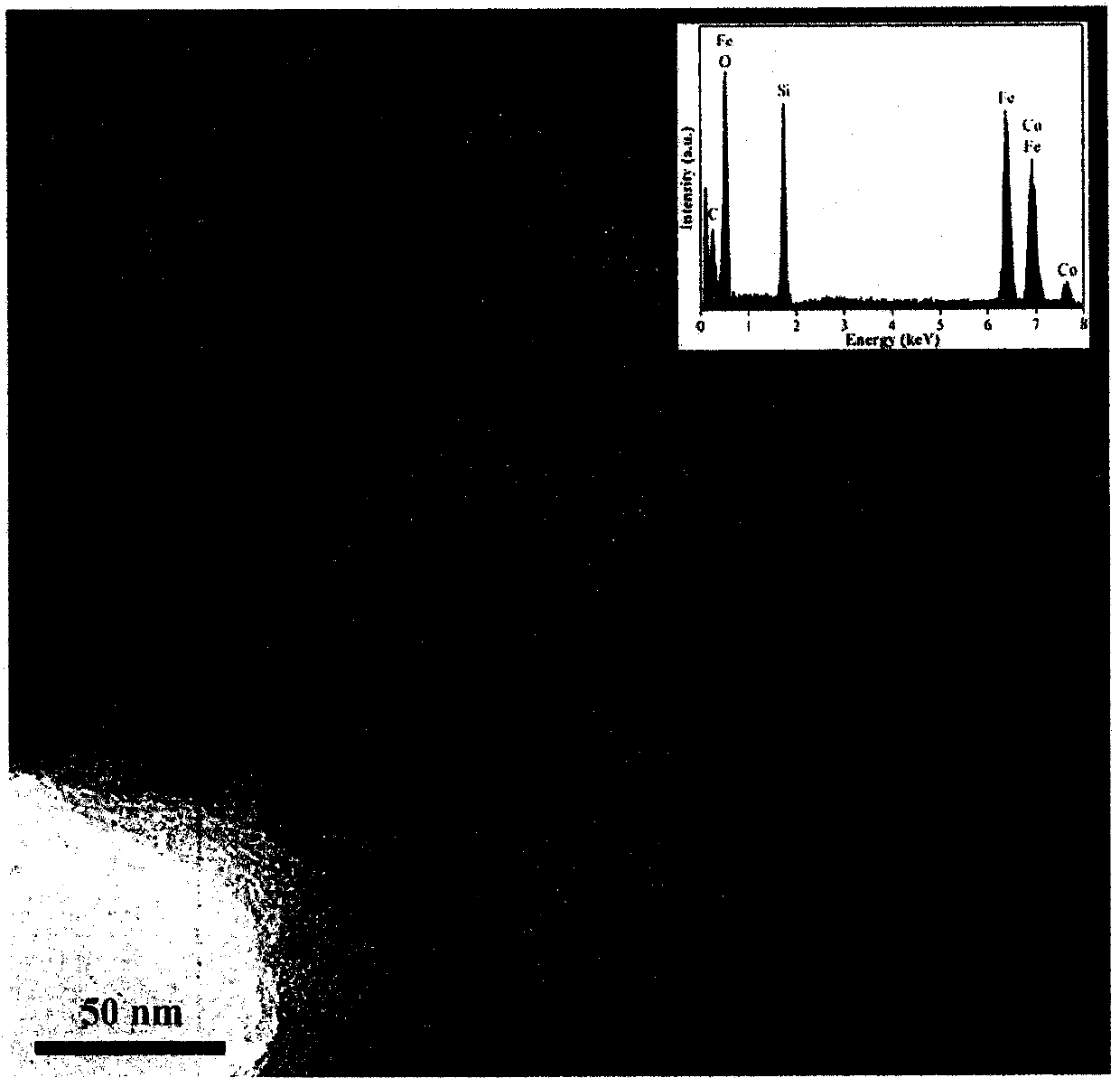

[0034] Fe 3 o 4 Preparation of micelles: Under a nitrogen atmosphere, 2g of ferric chloride and 0.8g of ferric chloride were dissolved in 10ml of deionized water, sonicated to dissolve them completely, and the above solution was added dropwise to 100ml (1mol / L) of ammonia In the aqueous solution, a black sol was formed and stirred for 5 min.

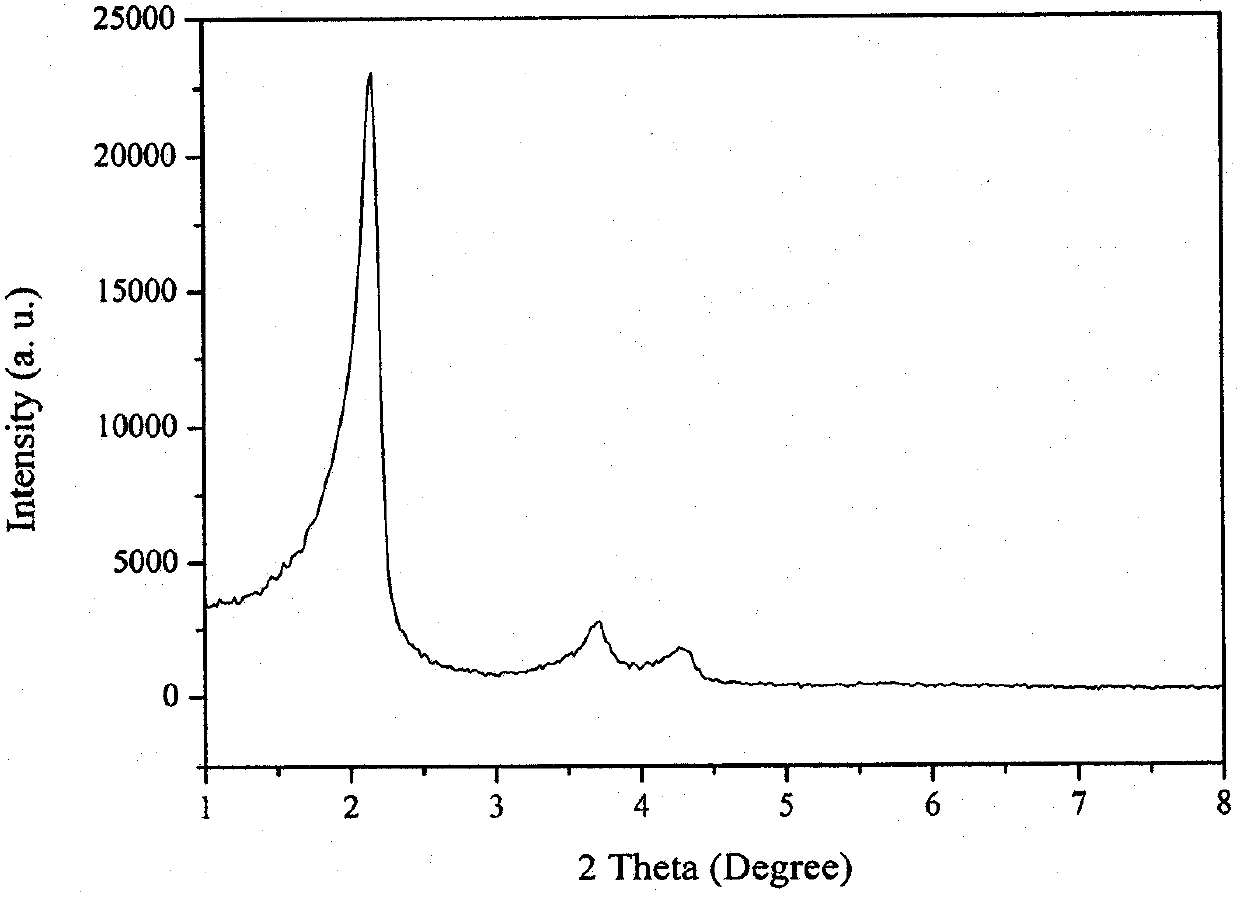

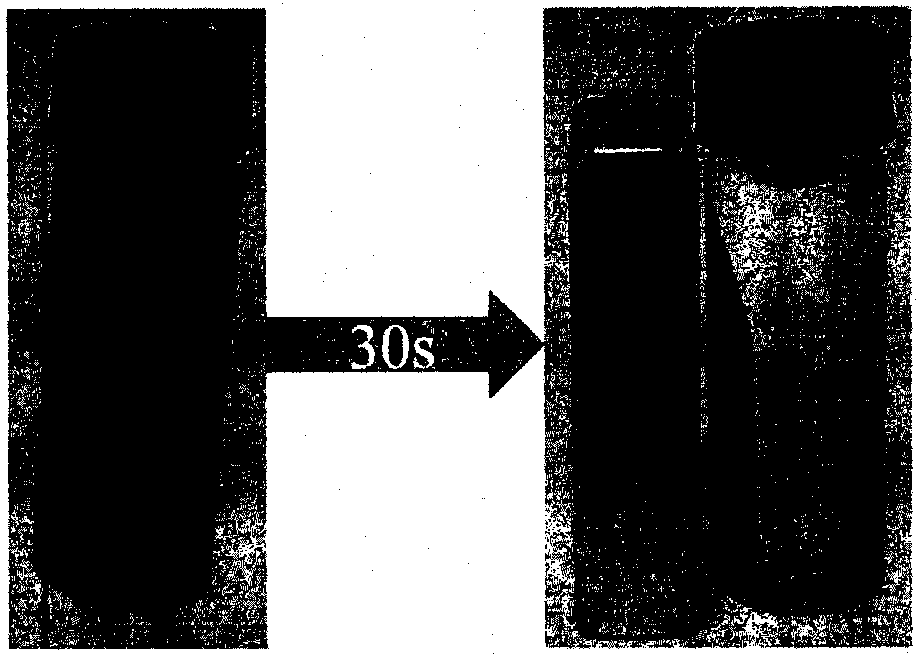

[0035] The synthetic steps of catalyst: 2.4g hexadecyltrimethylammonium bromide is dissolved in the mixed solution of 120ml deionized water and 10.5ml strong ammonia water, stirs 30min and makes it dissolve completely, adds dropwise 20ml Fe 3 o 4 For micelles, after stirring for 1 min, add 0.3 g of cobalt chloride to the above mixed solution, after stirring for 30 min, add 10 g of tetraethyl orthosilicate dropwise, and then stir for 2 h, and the final mixed sample is hydrothermally heated at 120 ° C for 24 h . The hydrothermal samples were washed three times with deionized water and ethanol, and dried at 60 °C. Finally, it was calci...

Embodiment 2

[0038] The preparation process of the iron oxide micelles is the same as in Example 1, and 1.2 g of ferric chloride and 0.8 g of ferric chloride are selected to form a black sol.

[0039] Use nickel chloride to replace cobalt chloride in embodiment 1, other preparation processes are identical with embodiment 1, choose 1.2g hexadecyltrimethylsilane, add 30ml Fe dropwise 3 o 4 For micelles, 10 g of tetraethylorthosilicate was added, and the final mixed sample was hydrothermally heated at 150° C. for 48 h. The hydrothermal samples were washed three times with deionized water and ethanol respectively, and dried at 60°C. Finally, it was calcined at 500°C for 6h in air atmosphere. The catalytic performance measurement procedure of the catalyst is the same as in Example 1. After 60 minutes of reaction, the Orange II removal rate is 100%, and the separation is complete after 35 seconds of magnetic separation.

Embodiment 3

[0041] The preparation process of the iron oxide micelles is the same as in Example 1, and 3 g of ferric chloride and 0.8 g of ferric chloride are selected to form a black sol.

[0042] Use manganese chloride to replace cobalt chloride in embodiment 1, other preparation processes are identical with embodiment 1, choose 3.6g hexadecyltrimethylsilane, add 10ml Fe dropwise 3 o 4 For micelles, 10 g of tetraethyl orthosilicate was added, and the final mixed sample was hydrothermally heated at 100° C. for 72 h. The hydrothermal samples were washed three times with deionized water and ethanol respectively, and dried at 60°C. Finally, it was calcined at 600°C for 8h in air atmosphere. The catalytic performance measurement procedure of the catalyst was the same as in Example 1. After 55 minutes of reaction, the Orange II removal rate was 100%, and the separation was complete after 32 seconds of magnetic separation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com