Treatment equipment for VOCs (Volatile Organic Chemicals) technological waste gas of packaging and printing industry

A technology for packaging, printing and processing equipment, applied in gas treatment, lighting and heating equipment, combustion methods, etc., can solve the problems of high energy consumption and low heat utilization efficiency, and achieve the effect of ensuring safe operation and avoiding process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

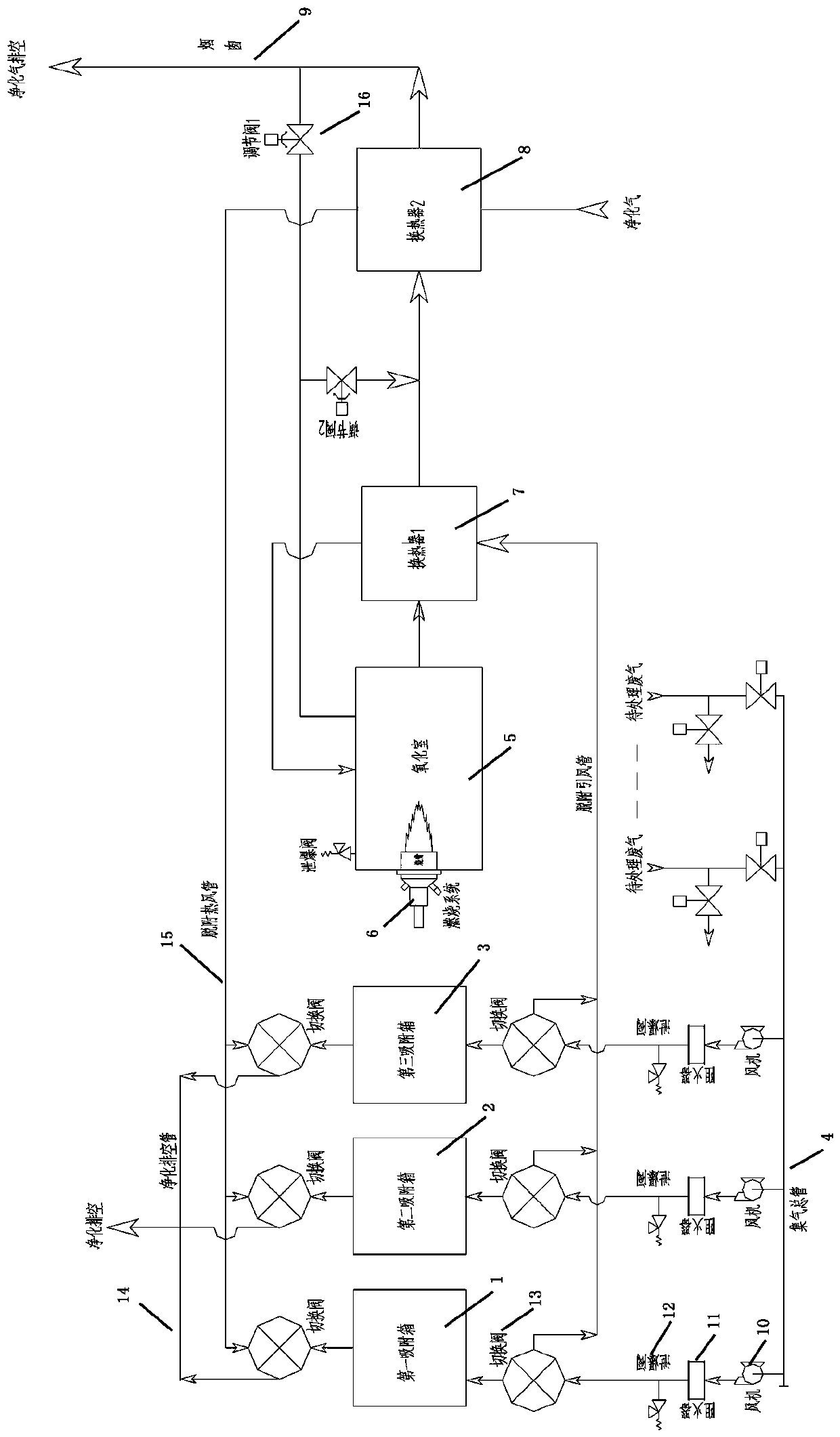

[0021] Such as figure 1 As shown, the treatment equipment for VOCs process waste gas in the packaging and printing industry mainly includes adsorption devices, oxidation chambers, combustion systems, and heat exchangers. The adsorption box is divided into the first adsorption box, the second adsorption box, and the third adsorption box. , each group of adsorption boxes is equally divided into multiple units, some units are in the adsorption state within the same period of time, intercepting VOCs, some units are in the desorption state, releasing VOCs, and realizing the concentration of exhaust gas. In the adsorption box, each unit is set With thermocouple, the monitoring operation is stable. The exhaust gas containing VOCS enters the adsorption device from the gas collection main pipe, and the honeycomb activated carbon inside the adsorption box adsorbs VOCS, and the treated exhaust gas is discharged through the purification and exhaust pipe; when the adsorption reaches satura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com