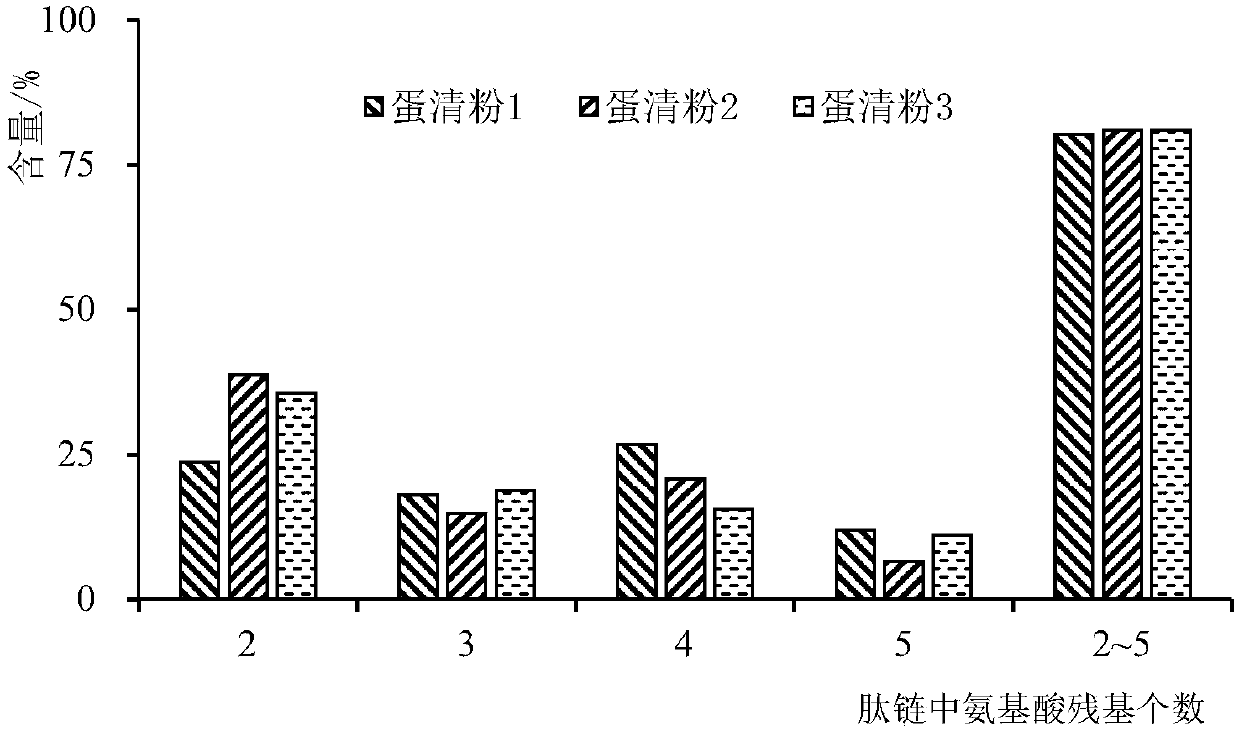

Preparation method of egg white powder from dipeptide-pentapeptide

A technology of egg white and egg white, which is applied in food science and other fields, can solve the problems of easy saturation of the carrier, slow absorption, and high energy consumption, and achieve the effects of reducing molecular weight, improving quality, and avoiding the desalination process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Take 10kg of fresh eggs, wash them, separate the egg whites and egg yolks to obtain 6 kg of egg whites, add 6L of deionized water to the fresh egg whites, keep the mixture at 90°C for 0.5h, cool to room temperature, and place the mixture in Carry out homogeneous treatment in the colloid mill to obtain the mixed solution A;

[0031] 2) Add 6g of alkaline protease and 6g of trypsin to the mixture A, stir the mixture A at a constant temperature at 50°C for 6h, after the reaction is completed, heat the mixture A at 90°C for 20min to terminate the enzymolysis reaction , to obtain the mixture B;

[0032] 3) Add 12 g of neutral protease and 6 g of papain to the mixed solution B, stir the mixed solution B at 40°C for 12 hours at a constant temperature, and after the reaction, heat the mixed solution B at 90°C for 20 minutes to terminate the enzymatic hydrolysis reaction , plate and frame filtration to separate the supernatant and precipitate, and collect the supernatant A; ...

Embodiment 2

[0057] 1) Take 10kg of fresh eggs, wash them, separate the egg whites and egg yolks, and obtain 6 kg of egg whites, add 3 L of deionized water to the fresh egg whites, keep the mixture at 70°C for 2 hours, cool to room temperature, and place the mixture in colloid Carry out homogeneous treatment in the mill to obtain the mixed solution A;

[0058] 2) Add 24g of alkaline protease to the mixed solution A, and stir the mixed solution A at 60°C for 12 hours at a constant temperature. After the reaction is completed, heat the mixed solution A at 90°C for 20 minutes to terminate the enzymatic hydrolysis reaction to obtain the mixed solution Liquid B;

[0059] 3) Add 6g of compound protease and 6g of flavor protease to the mixed solution B, stir the mixed solution B at a constant temperature of 50°C for 6h, after the reaction is completed, heat the mixed solution B at 90°C for 20min to terminate the enzymatic hydrolysis reaction, Centrifuge to separate the supernatant and precipitat...

Embodiment 3

[0065] 1) Take 10kg of fresh eggs, wash them, separate the egg whites and egg yolks to obtain 6 kg of egg whites, add 12L of deionized water to the fresh egg whites, keep the mixture at 80°C for 1 hour, cool to room temperature, and place the mixture in colloid Carry out homogeneous treatment in the mill to obtain the mixed solution A;

[0066] 2) Add 24 g of trypsin to the mixed solution A, stir the mixed solution A at 55°C for 10 hours at a constant temperature, and after the reaction is completed, heat the mixed solution A at 90°C for 20 minutes to terminate the enzymatic hydrolysis reaction to obtain the mixed solution B;

[0067] 3) Add 12 g of bromelain and 12 g of flavor protease to the mixed solution B, stir the mixed solution B at a constant temperature at 45°C for 12 hours, after the reaction is completed, heat the mixed solution B at 90°C for 20 minutes to terminate the enzymatic hydrolysis reaction, Vacuum drum filtration to separate supernatant and precipitate, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com