Instant crab leg processing method

A processing method, crab leg technology, applied in the field of instant crab leg processing, can solve the problems such as difficult to reduce the allergenicity of TM and AK, and achieve the effects of reducing allergenicity, easy large-scale production, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

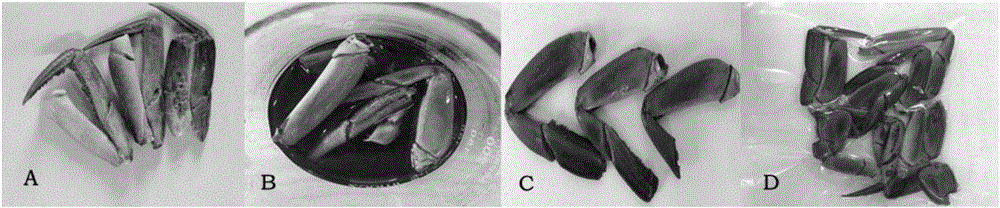

Image

Examples

Embodiment 1

[0040] Embodiment 1: adopt the processing method of galactose and arabinose mixed salt sugar water treatment (2.0% galactose, 2.0% arabinose, 1.0% salt, 95% water, pH8.5) to produce instant crab legs, comprising the following steps:

[0041] (1) Pre-treatment of crab legs: choose live crabs or frozen crabs as raw materials, wash the mud and dirt attached to the surface of the crab body with clean water, take the crab legs with complete shape and wash them with ice water; place the crab legs Soak in salt-sugar water (2.0% galactose, 2.0% arabinose, 1.0% salt, 95% water, pH8.5) at 4°C for 20 minutes, the ratio of crab legs to salt-sugar water is 1:2 (w:v);

[0042] (2) Pre-cooking: put the soaked crab legs into a steamer, and pre-cook them at 100°C for 3 minutes; cool the boiled crab legs to room temperature, and send them to a 4°C freezer;

[0043] (3) Low-temperature marinating: soak the crab legs again in salted sugar water (2.0% galactose, 2.0% arabinose, 1.0% salt, 95% wate...

Embodiment 2

[0046] Embodiment 2: adopt the processing method of galactose and arabinose mixed salt sugar water treatment (1% galactose, 3% arabinose, 2% salt, 94% water, pH8.0) to produce instant crab legs, comprising the following steps:

[0047] (1) Pre-treatment of crab legs: choose live crabs or frozen crabs as raw materials, wash the mud and dirt attached to the surface of the crab body with clean water, take the crab legs with complete shape and wash them with ice water; place the crab legs Soak in salt-sugar water (1% galactose, 3% arabinose, 2% salt, 94% water, pH 8.0) at 4°C for 15 minutes, the ratio of crab legs to salt-sugar water is 1:1 (w:v);

[0048] (2) Pre-cooking: put the soaked crab legs into a steamer, and pre-cook them at 100°C for 5 minutes; cool the boiled crab legs to room temperature, and send them to a 4°C freezer;

[0049] (3) Low-temperature marinating: soak the crab legs in salt-sugar water (1% galactose, 3% arabinose, 2% salt, 94% water, pH8.0) at 4°C for 1.5 ...

Embodiment 3

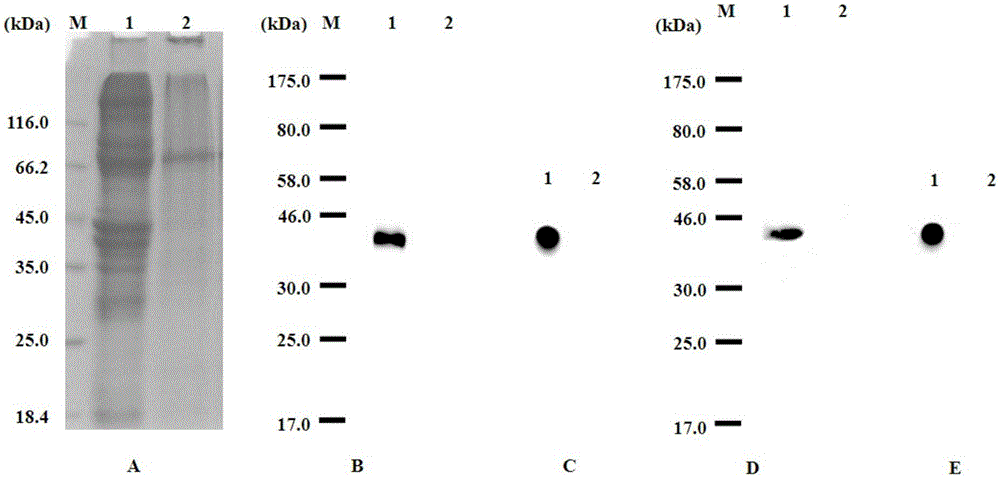

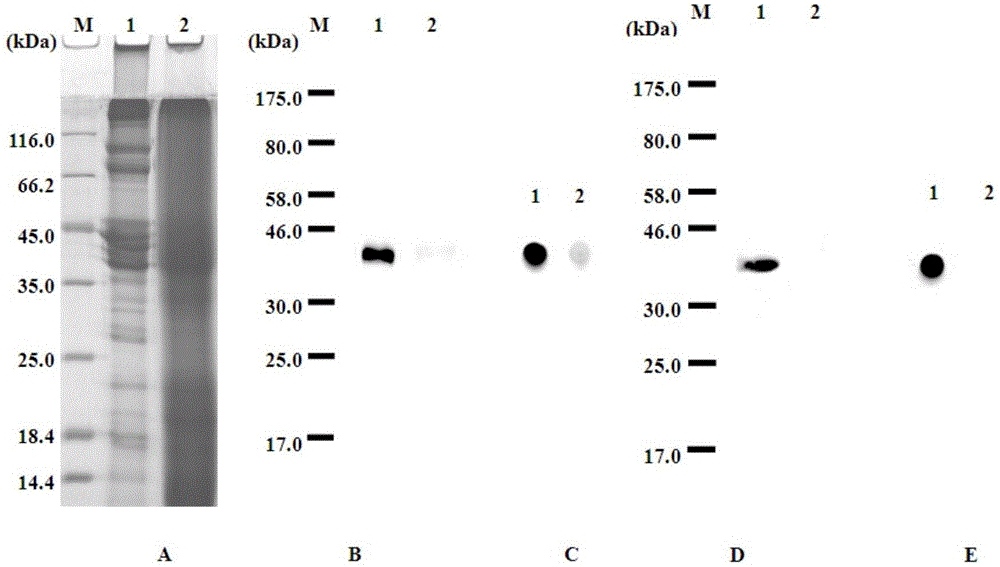

[0052] Embodiment 3: Separation and purification of TM and AK and Maillard reaction

[0053] (1) TM purification Fresh crab meat was placed in 10 times the volume (v / w) of ice-cold 20mmol / LTris-HCl (pH=7.5), mashed with a tissue grinder, centrifuged at 8000g, 4°C for 10min, and left Take the precipitate part; re-mash the precipitate in 10 times the volume of Tris-HCl buffer, repeat the above steps (mash, centrifuge) 4 times; dissolve the precipitate obtained by the last centrifugation in 100mmol / L Tris-HCl buffer (pH7.5, containing 0.5mol / LNaCl); prepare the above solution into acetone powder, and then dissolve the acetone powder in 10 times the volume (v / w) of 20mmol / LTris-HCl (pH=7.5) solution (containing 1mol / LKCl and 10mmol / Lβ-mercaptoethanol), and stirred overnight; centrifuged at 20,000g, 4°C for 20min, took the supernatant, added 1mol / LHCl to adjust the pH to 4.5, and allowed TM to precipitate near the isoelectric point, and let it stand for 2h. , centrifuged at 15000...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com