Remineralizing material for use on demineralized enamel surface and preparation method thereof

A technology of remineralization and enamel, applied in dental preparations, dentistry, dental prostheses, etc., to achieve the effects of low sensitization, good biocompatibility, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A remineralization material for the surface of demineralized tooth enamel, prepared by the following steps,

[0031] (1) Synthesis of carboxymethyl chitosan-amorphous calcium phosphate polymer

[0032] Under the sufficient stirring of room temperature and magnetic stirrer, add carboxymethyl chitosan 200mg to 30ml deionized water, after being completely dissolved, dipotassium hydrogen phosphate 47.04mg, react 15min, obtain A solution; With sufficient stirring, add 94.08mg of calcium chloride dihydrate to 10ml of deionized water to form liquid B;

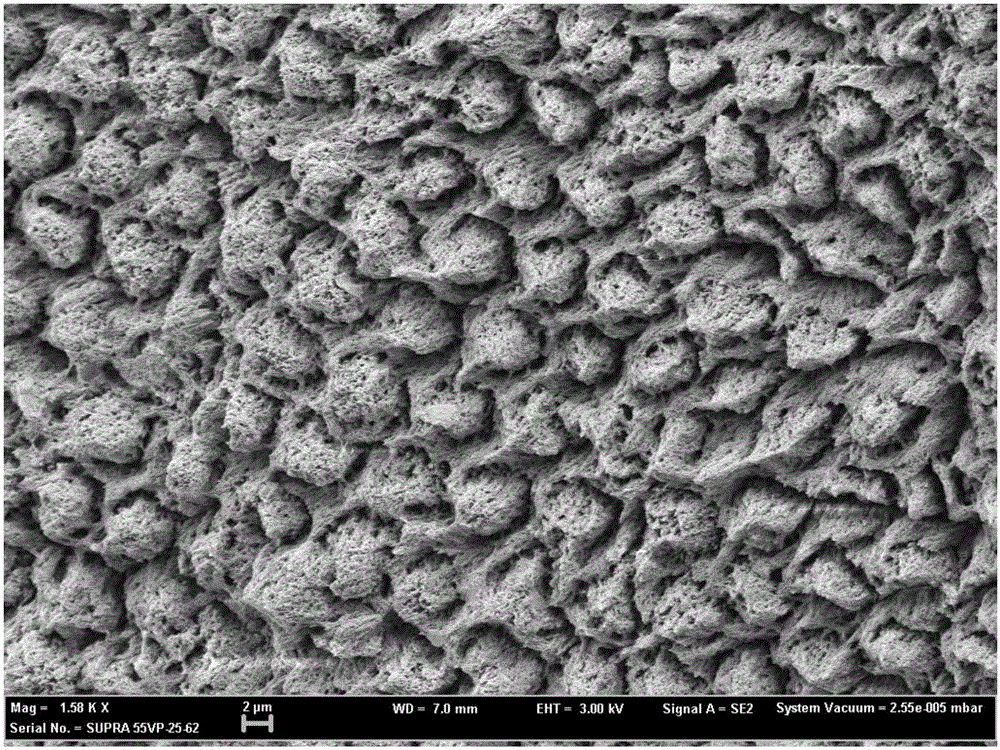

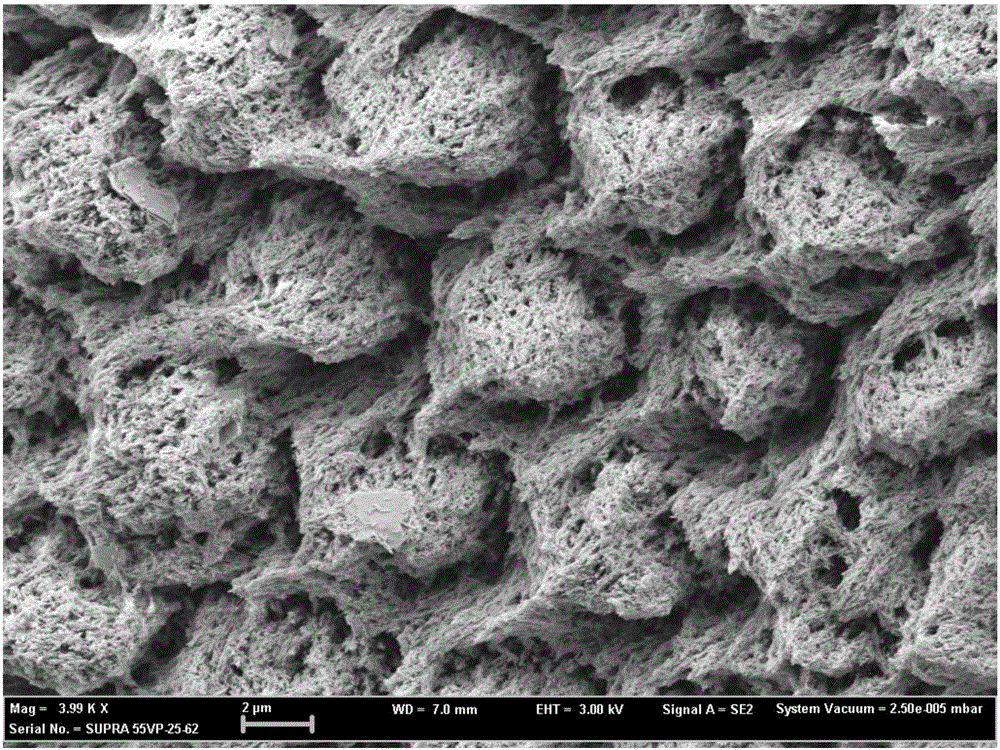

[0033] Under normal temperature and sufficient stirring with a magnetic stirrer, liquid B is added dropwise to liquid A to form a mixed solution of carboxymethyl chitosan-amorphous calcium phosphate (CMC-ACP); the formed carboxymethyl chitosan - The average particle size of the amorphous calcium phosphate nanocomposite is 50-200 nm.

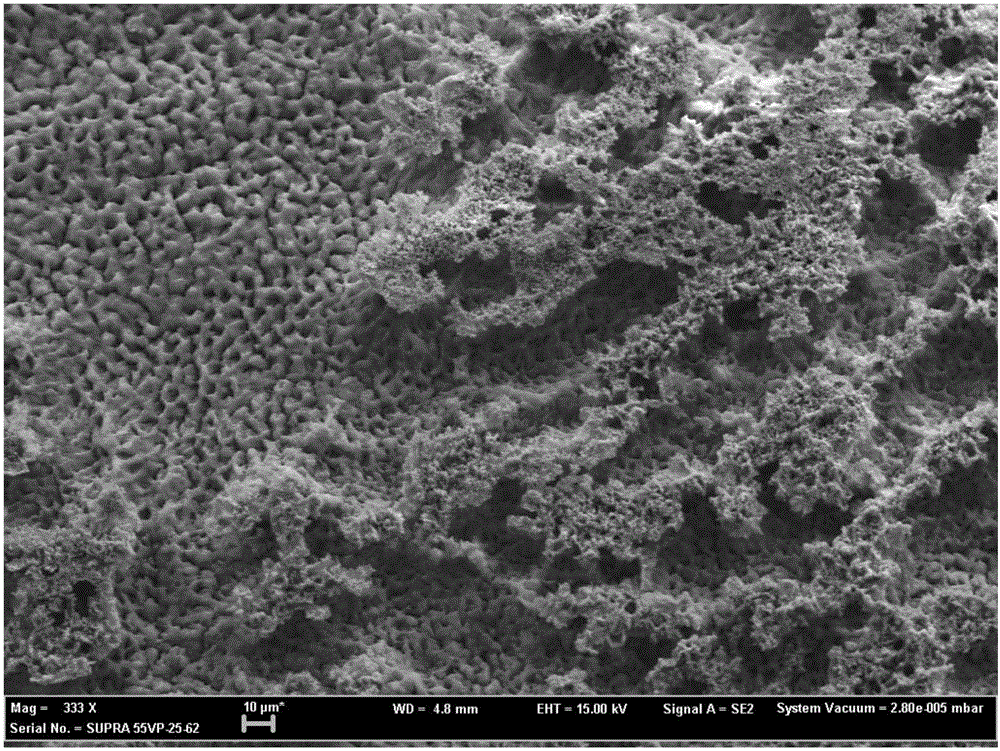

[0034] (2) Formation of mineralized materials

[0035] Under normal temperature and suffici...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com