A kind of method that metal salt catalyzes cellulose to prepare levulinic acid ester

A technology of levulinate and cellulose, which is applied in the field of catalyzing the direct alcoholysis of cellulose to prepare levulinate, can solve the problems of low catalytic efficiency, corrosion of liquid inorganic acid, reduced reaction activity, etc., and achieves good reusability, The effect of mild reaction conditions and short reaction times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

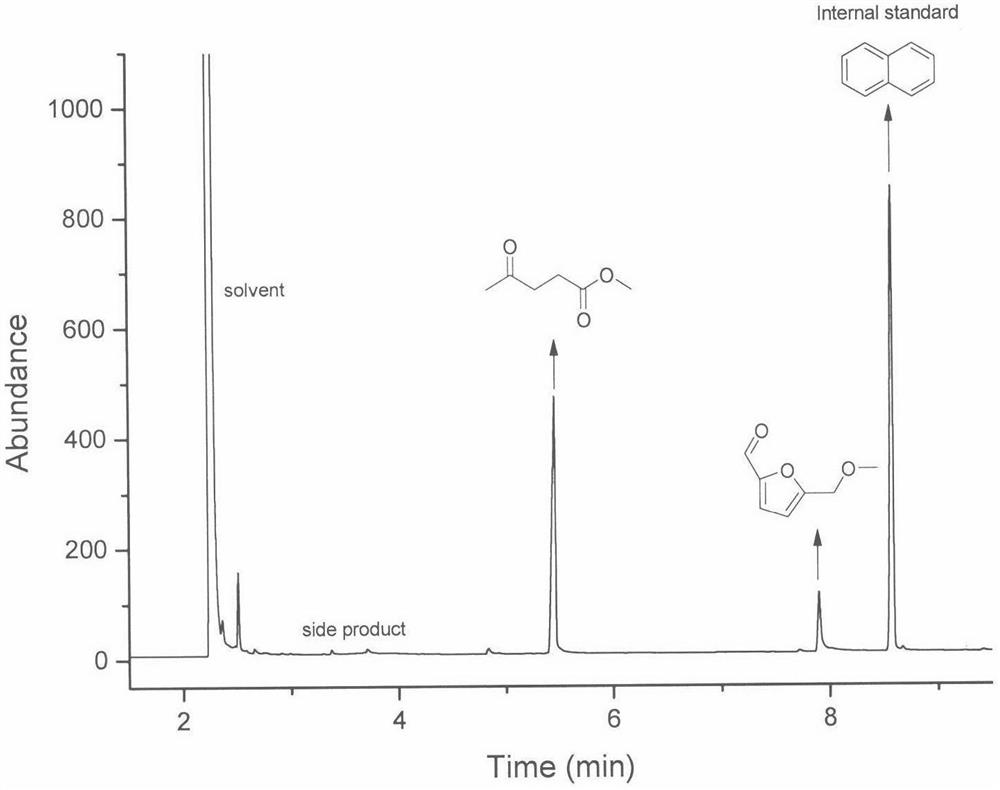

[0026] 500mg microcrystalline cellulose (mass concentration in alcohol is 4.5%), 0.6mL water, 14mL methanol and 0.6mmol Al 2 (SO 4 ) 3 18H 2 O(Al 3+ 1.2 mmol) was added into a polytetrafluoroethylene reactor, and heated with 800W microwave power for 2 minutes to 180° C. under air atmosphere, and reacted for 4 minutes. The reaction product was analyzed by GC-MS and compared with the standard product of methyl levulinate to confirm that the main product was indeed methyl levulinate. Using naphthalene as an internal standard, the yield of methyl levulinate was 70.6% through quantitative analysis by gas chromatography.

Embodiment 2

[0028] Substantially the same as Example 1, the difference is: adopt 1.2mmol AlCl 3 Instead of 0.6mmolAl in Example 1 2 (SO 4 ) 3 18H 2 O, the detection result is that the yield of methyl levulinate obtained in the embodiment of the present invention is 8.2%.

Embodiment 3

[0030] Basically the same as Example 1, the difference is: adopt 1.2mmolAl (NO 3 ) 3 9H 2 O replaces 0.6mmol Al in Example 1 2 (SO 4 ) 3 18H 2 O, the detection result is that the yield of methyl levulinate obtained in the embodiment of the present invention is 12.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com