A kind of aluminum alloy composite foil and preparation method thereof

A composite foil and aluminum alloy technology, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of small size, short service life, and inability to meet the needs of materials, and achieve mechanical properties and corrosion resistance Excellent, improve the preparation process technology, prevent the effect of penetration erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

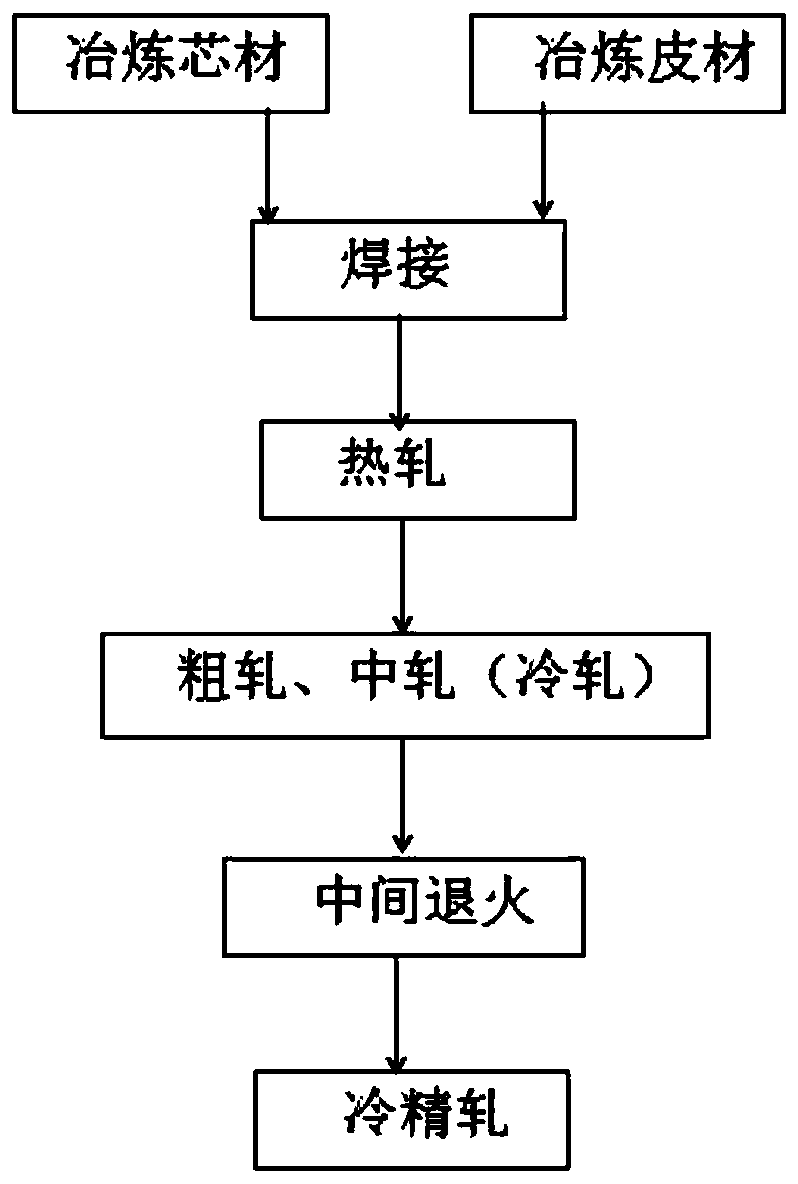

Method used

Image

Examples

Embodiment 1

[0052] 1. Prepare core material and skin material by smelting. The composition of core material and skin material is shown in Table 1. The raw materials of each element are respectively placed in a melting furnace for smelting to obtain core material and skin material respectively.

[0053] Table 1 Composition of core material and skin material

[0054]

[0055] The smelting conditions of the core material are as follows: according to the composition of the core material in Table 1, add the raw materials of each element into the melting furnace, the melting temperature is 765 ° C, electromagnetic stirring is performed twice, 10 minutes each time, and then refined at 755 ° C for 10 minutes , and then cast at a temperature of 710°C to obtain the required core material.

[0056] The smelting conditions of the skin material are: add the raw materials of each element into the melting furnace according to the composition of the skin material in Table 1, the melting temperature is...

Embodiment 2

[0068] 1. Prepare core material and skin material by smelting. The composition of core material and skin material is shown in Table 2. The raw materials of each element are respectively placed in a melting furnace for smelting to obtain core material and skin material respectively.

[0069] Table 2 Composition of core material and skin material

[0070]

[0071] The smelting conditions of the core material are: add the raw materials of each element into the melting furnace according to the composition of the core material in Table 2, the melting temperature is 755°C, electromagnetic stirring is performed twice, each time for 10 minutes, and then refined at 745°C for 10 minutes , and then cast at a temperature of 705°C to obtain the required core material.

[0072] The smelting conditions of the skin material are: add the raw materials of each element into the melting furnace according to the composition of the skin material in Table 2, the melting temperature is 750°C, elec...

Embodiment 3

[0084] 1. Prepare core material and skin material by smelting. The composition of core material and skin material is shown in Table 3. The raw materials of each element are respectively placed in a melting furnace for smelting to obtain core material and skin material respectively.

[0085] Table 3 Composition of core material and skin material

[0086]

[0087] The smelting conditions of the core material are as follows: according to the composition of the core material in Table 3, add the raw materials of each element into the melting furnace, the melting temperature is 750 ° C, electromagnetic stirring is performed twice, 10 minutes each time, and then refined at 740 ° C for 10 minutes , and then cast at a temperature of 700 ° C to obtain the required core material.

[0088] The smelting conditions of the skin material are: add the raw materials of each element into the melting furnace according to the composition of the skin material in Table 3, the melting temperature ...

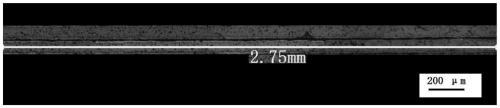

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com