A kind of conductive polymer coated doped lithium ion battery positive electrode material and its synthesis method

A conductive polymer and lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as erosion, poor rate performance, poor interface stability, etc., to inhibit erosion, improve rate performance and cycle stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

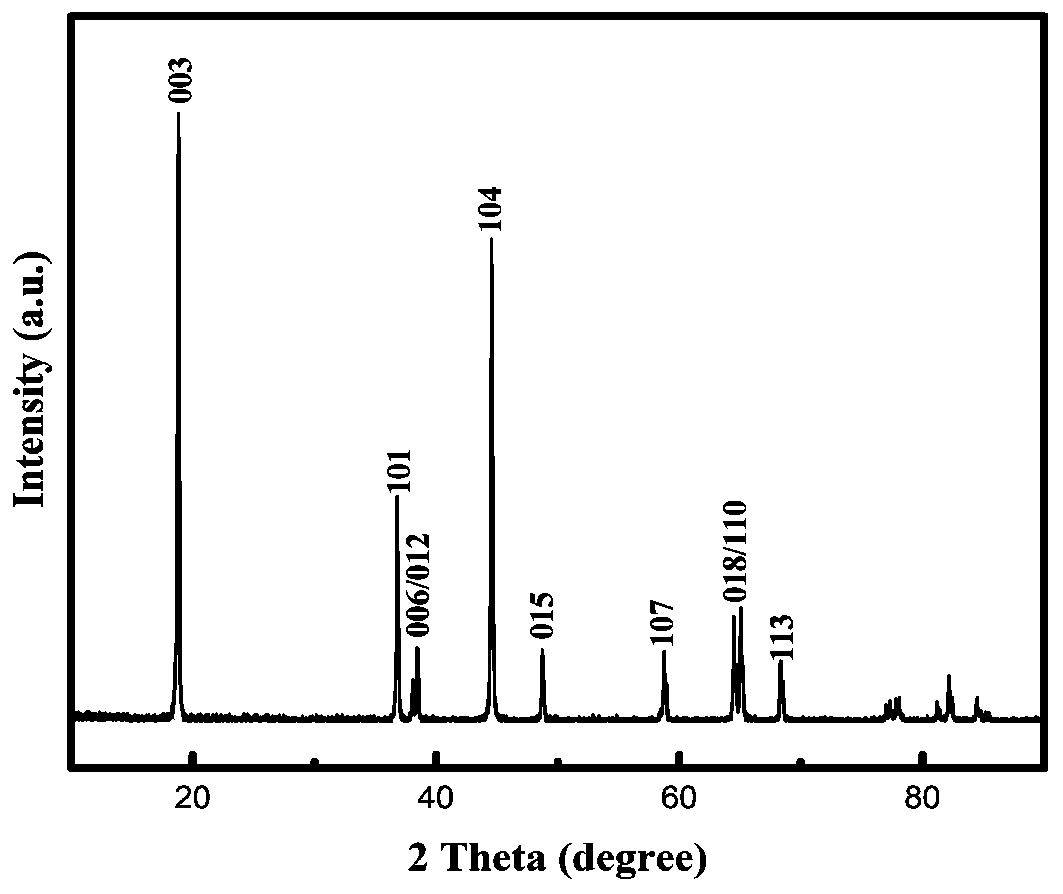

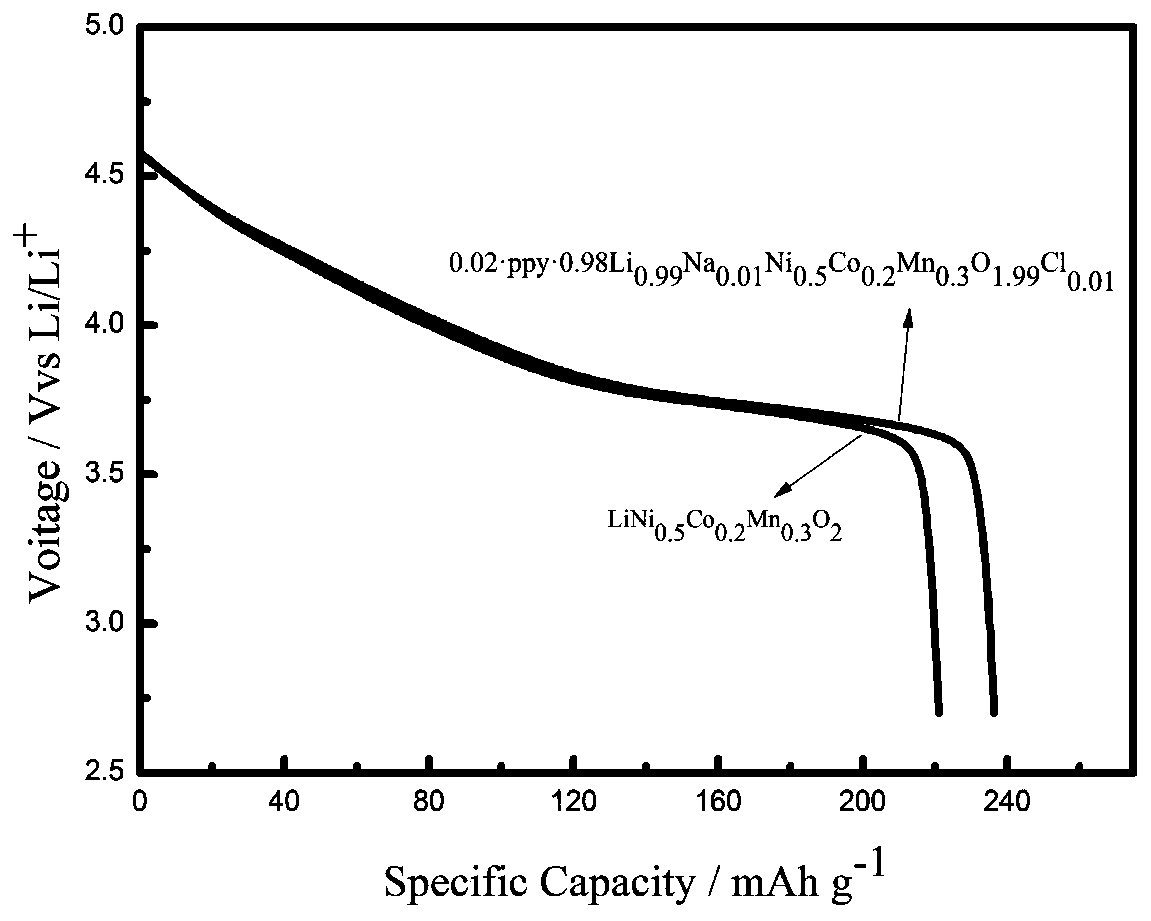

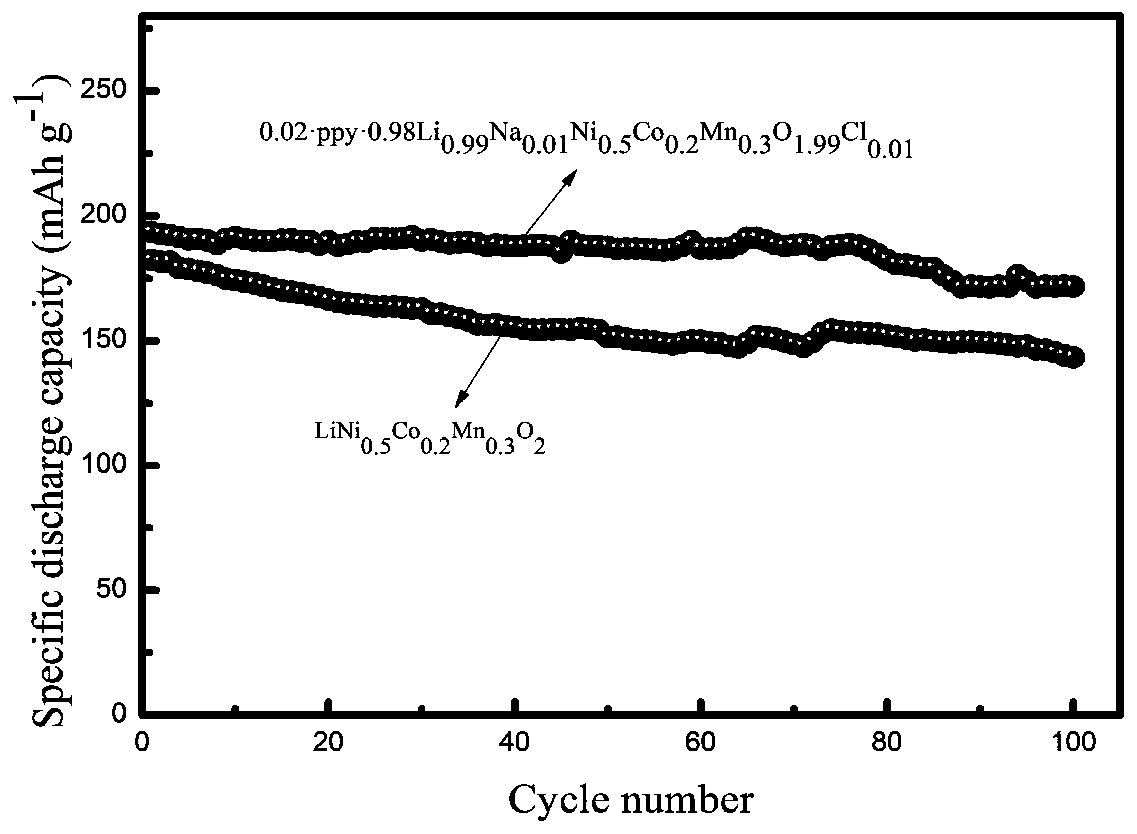

Embodiment 1

[0030] Weigh Ni separately 0.5 co 0.2 mn 0.3 (OH) 2 9.2524g, LiOH·H 2 O is 3.3874g, Li 2 CO 3 0.9282g and 0.587g NaCl, put it into a ball mill jar filled with 17mL of absolute ethanol, then add zirconium balls, the ratio of material to ball is 1:6, ball mill at 400rpm for 4h, and place in a blast drying oven at 60°C Dry for 4 hours, weigh 6g and put it into a resistance box for pre-calcination at 480°C for 3h, then calcined at 880°C for 12h, and the heating rate is 5°C / min to obtain the sample. Weigh 3g of the sample doped with NaCl, dissolve it in a beaker with distilled water, place it on a magnetic stirrer, stir for 30min, then add 1.74g of surfactant sodium propanesulfonate to the beaker, stir for 10min, and then Add 1.88 g of oxidant sodium thiosulfate, stir for 10 minutes, wash, filter with suction, and dry in a blast drying oven at 60°C for 12 hours. Put the dried sample on filter paper in a petri dish, and put In a small aluminum foil box containing 0.06 g of po...

Embodiment 2

[0033] Weigh Ni separately 0.5 co 0.2 mn 0.3 (OH) 2 9.2524g, LiOH·H 2 O is 3.3874g, Li 2 CO 3 0.9282g and 1.762g NaCl, put it into a ball mill jar filled with 17mL of absolute ethanol, then add zirconium balls, the ratio of material to ball is 1:6, ball mill at 400rpm for 4h, and place in a blast drying oven at 60°C Dry for 4 hours, weigh 6g and put it into a resistance box for pre-calcination at 480°C for 3h, then calcined at 880°C for 12h, with a heating rate of 5°C / min to obtain a doped sample. Weigh the NaCl-doped sample 3g again, dissolve it in a beaker equipped with distilled water, place it on a magnetic stirrer, stir for 30min, then add surfactant sodium propanesulfonate 1.74g in the beaker, after stirring for 10min, then Then add 1.88g of sodium thiosulfate as an oxidant, stir for 10 minutes, wash, filter with suction, and dry in a blast drying oven at 60°C for 12 hours. Put it in a small aluminum foil box containing 0.06g of polypyrrole, the amount of conducti...

Embodiment 3

[0035] Weigh Ni separately 0.5 co 0.2 mn 0.3 (OH) 2 9.2524g, LiOH·H 2 O is 3.3874g, Li 2 CO 3 0.9282g and 2.937g NaCl, put it into a ball mill jar filled with 17mL of absolute ethanol, then add zirconium balls, the ratio of material to ball is 1:6, ball mill at 400rpm for 4h, and place in a blast drying oven at 60°C Dry for 4 hours, weigh 6g and put it into a resistance box for pre-calcination at 480°C for 3h, then calcined at 880°C for 12h, with a heating rate of 5°C / min to obtain a doped sample. Weigh the NaCl-doped sample 3g again, dissolve it in a beaker equipped with distilled water, place it on a magnetic stirrer, stir for 30min, then add surfactant sodium propanesulfonate 1.74g in the beaker, after stirring for 10min, then Then add 1.88g of sodium thiosulfate as an oxidant, stir for 10 minutes, wash, filter with suction, and dry in a blast drying oven at 60°C for 12 hours. Put it in a small aluminum foil box containing 0.06g of polypyrrole, the amount of conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com