A kind of preparation method of single crystal type high-nickel ternary positive electrode material

A cathode material, high nickel technology, applied in chemical instruments and methods, nickel compounds, electrical components, etc., can solve the problems of easy formation of impurity phase, unstable electrochemical performance, long reaction time, high price, etc. The effect of nickel mixing phenomenon, good electrochemical performance, good liquid phase environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A method for preparing a single-crystal high-nickel ternary positive electrode material, comprising the following steps:

[0029] Select nickel-cobalt-manganese hydroxide precursor or nickel-cobalt-aluminum hydroxide precursor as the reaction precursor;

[0030] The reaction precursors are purchased from the market or prepared in the laboratory.

[0031] Select two or more molten inorganic salts as mixed molten salts;

[0032] The molar ratio between two or more mixed molten salts is arbitrary, as long as the melting point of the mixed molten salts is not higher than 800°C.

[0033] The heating temperature is not lower than the melting point of the mixed molten salt, and the preferred heating temperature range in this application is 650-800°C.

[0034] Mix the reaction precursor, lithium salt, and mixed molten salt in a molar ratio of 1.0:1.1:x evenly, put it into a crucible, heat it to 650-800°C at a heating rate of 2-10°C / min and keep it for 2-30 Hours, naturally c...

Embodiment 1

[0040] 0.1mol precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2, 0.11mol LiOH, 0.05mol Li 2 SO 4 -Cs 2 SO 4 Mix molten salt (molar ratio 1:1, melting point about 740°C) and mix evenly, put it into a crucible, heat it to 780°C at a heating rate of 10°C / min, keep it for 15 hours, and cool it down to room temperature naturally. Washed with ionic water three times, dried in vacuum at 120°C for 3 hours, then put into a crucible, heated to 750°C at a heating rate of 10°C / min, kept for 6 hours, and cooled naturally to room temperature to obtain single crystal 811 (LiNi 0.8 mn 0.1 co 0.1 o 2 ) ternary material.

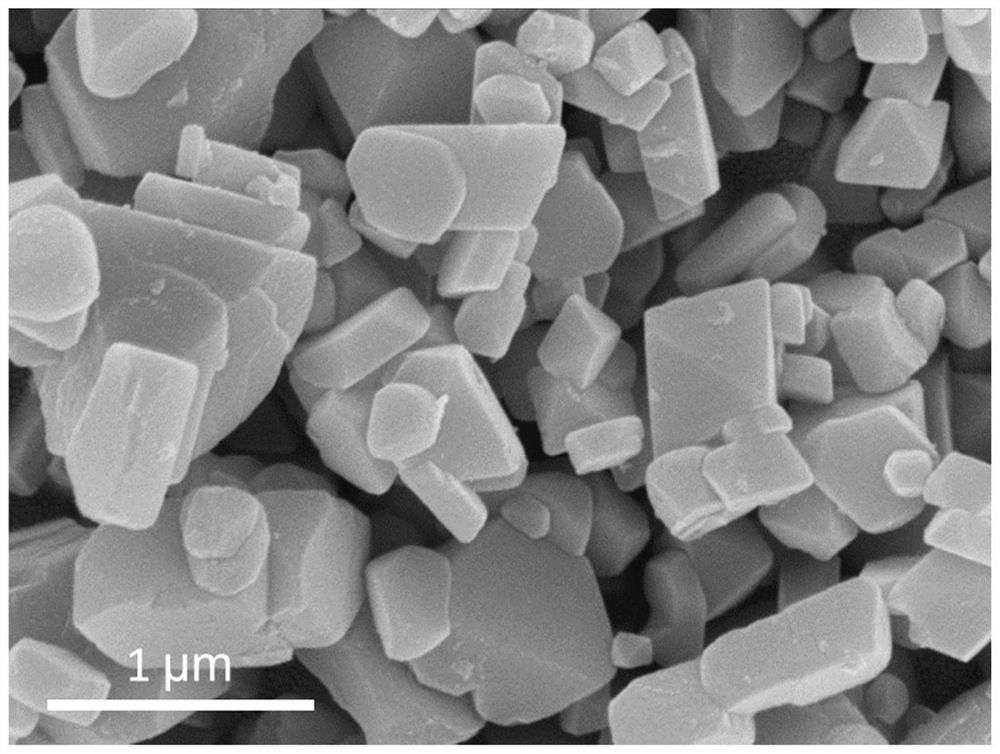

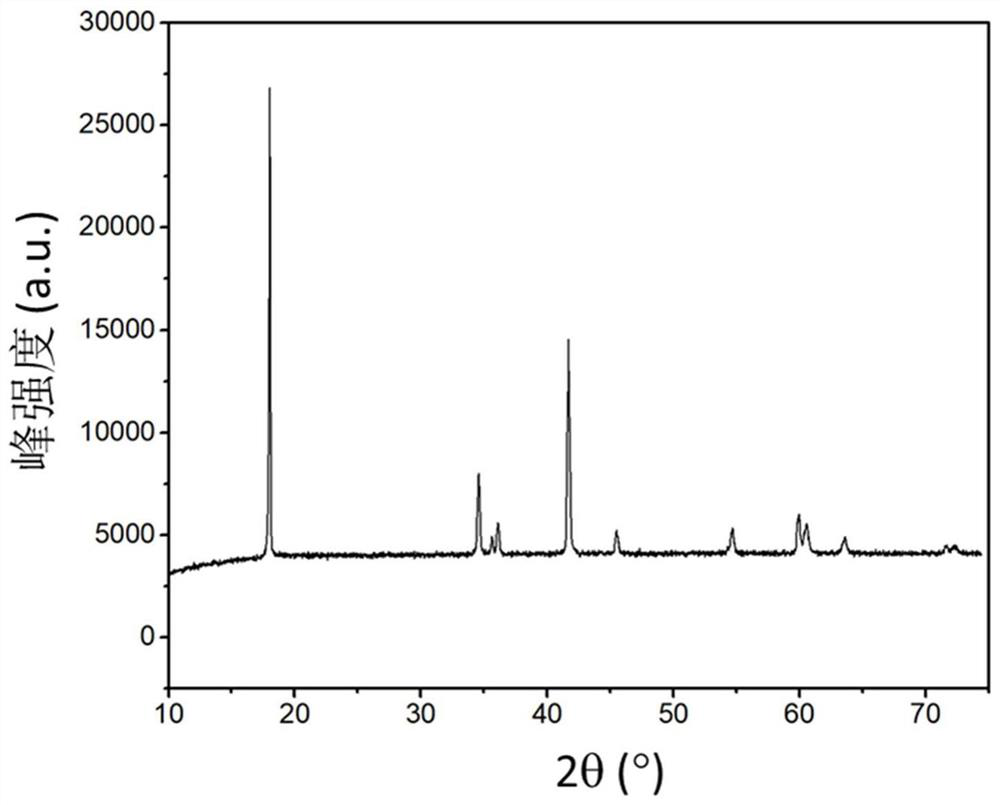

[0041] From figure 1 It can be seen that the formed ternary material has the morphology of single crystal polyhedron. From figure 2 It can be seen from the XRD data that the crystallinity is very good and the structure is highly ordered.

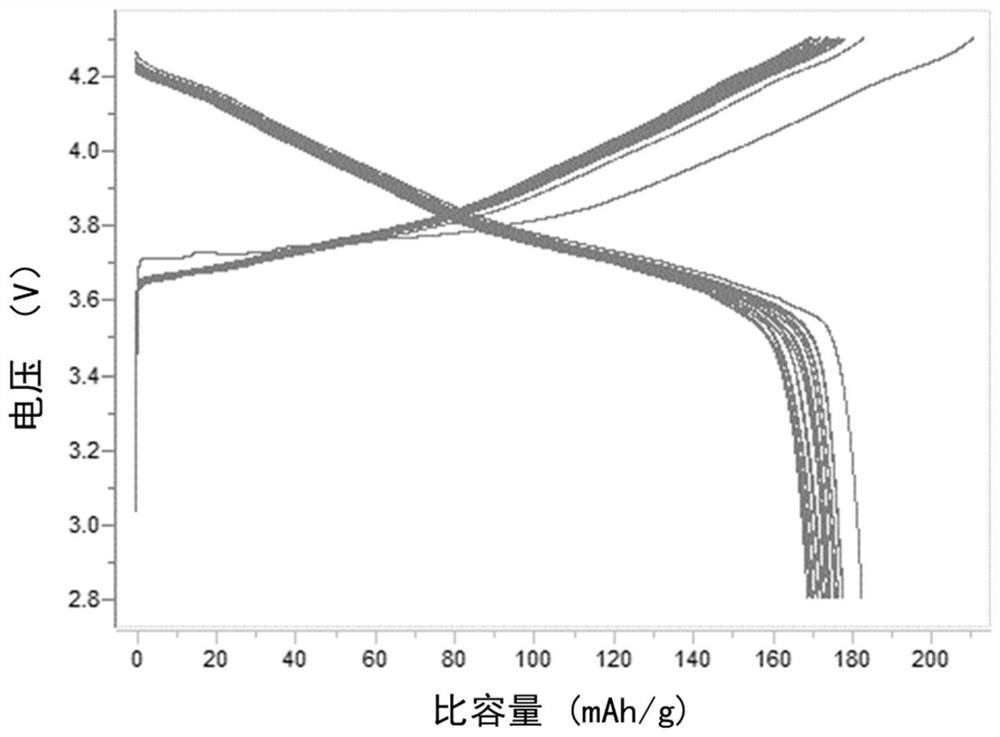

[0042] Electrochemical test: Mix the active material with conductive carbon and PVDF binder in NMP at a ratio of 90:5:5 and coat it on ...

Embodiment 2

[0044] 0.1mol precursor Ni 0.85 co 0.1 Al 0.05 (OH) 2.05 , 0.11mol LiOH, 0.05mol Li 2 SO 4 -K 2 SO 4 Mix molten salt (molar ratio 8:2, melting point about 530°C) and mix evenly, put it into a crucible, heat it to 750°C at a heating rate of 10°C / min, keep it for 15 hours, cool it down to room temperature naturally, and use the mixture Washed with ionic water for 3 times, vacuum dried at 120°C for 3 hours, then placed in a crucible, heated to 750°C at a heating rate of 10°C / min, kept for 6 hours, and naturally cooled to room temperature to obtain LiNi 0.85 co 0.10 Al 0.05 o 2 .

[0045] From Figure 4 It can be seen that the ternary material has the morphology of single crystal polyhedron. From Figure 5 It can be seen from the XRD data that the crystallinity is very good and the structure is highly ordered.

[0046] Electrochemical test: Mix the active material with conductive carbon and PVDF binder in NMP at a ratio of 90:5:5 and coat it on an aluminum foil. Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com