Microalgae grease extraction and separation method, equipment and application

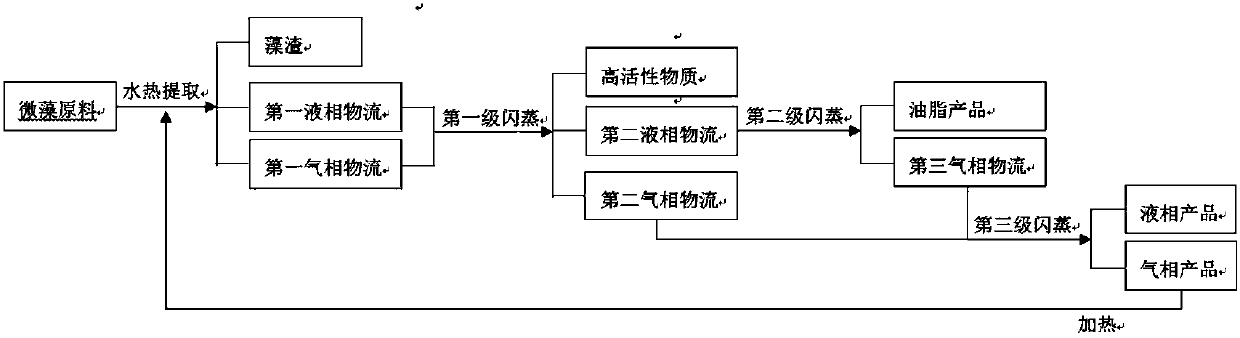

A technology of microalgae oil and separation method, which is applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc. It can solve the problems of complex oil phase components, easy pollution, and high energy consumption of extractants.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

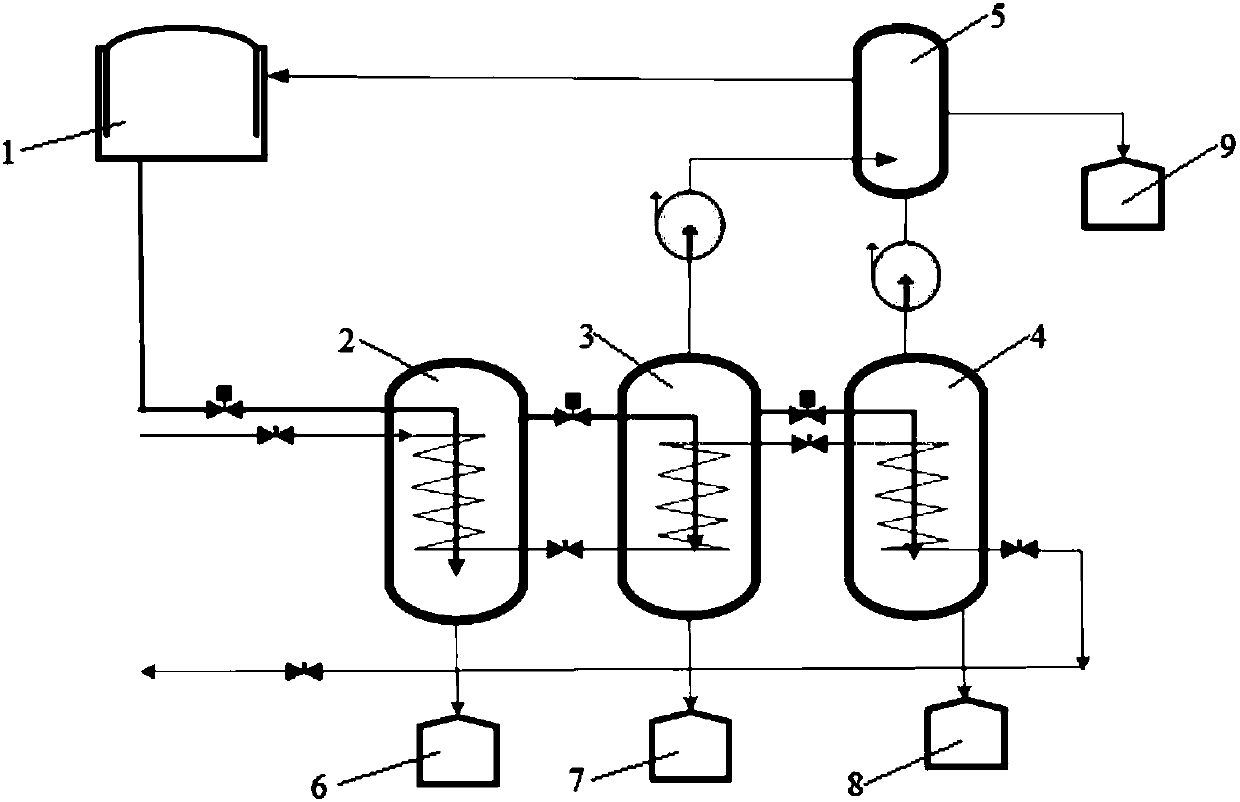

Embodiment 1

[0078] (1) Select Nannochloropsis algae pulp (moisture content 5%-15%) as raw material, the raw material enters the hydrothermal reaction tower from the raw material pool, the hydrothermal is kept in a subcritical state, and the filling gas is nitrogen inert gas to exclude oxygen The influence on the hydrothermal reaction; the temperature of the hydrothermal reaction tower is 270-280°C, the pressure is 6.5-7.5Mpa, and the residence time is 5min; the first liquid phase stream, the first gas phase stream and algae residue are obtained; among them, the first liquid Phase flow includes water phase and organic phase. The organic phase includes the moisture-heat decomposition substances of grease, protein, and carbohydrates and the water-insoluble organic matter generated by their mutual reactions. The water phase mainly includes subcritical water and aldehydes and amino acids dissolved in water. etc., the first gas phase stream is small molecular gases such as ammonia and carbon dio...

Embodiment 2

[0086] (1) Select low-protein and high-fat microalgae (comprising euphthalmia, yellow silk algae, and different chlorella) algae pulp (moisture content 5%-15%) as raw materials, enter the hydrothermal reaction tower, and hydrothermally Keep in a subcritical state, the filling gas is nitrogen inert gas to eliminate the influence of oxygen on the hydrothermal reaction; the temperature of the hydrothermal reaction tower is 260-270°C, the pressure is 6-6.5Mpa, and the residence time is 5min; the first liquid phase is obtained Stream, the first gas phase stream and algae residue; Wherein, the first liquid phase stream comprises water phase and organic phase, and organic phase comprises the moisture-heat decomposition substance of grease, protein, carbohydrate and the water-insoluble organic matter of the generation of its mutual reaction, The water phase mainly includes subcritical water and aldehydes and amino acids dissolved in water. The first gas phase stream is small molecular ...

Embodiment 3

[0093] (1) choose golden algae algae pulp (moisture content 5%-15%) as raw material, enter the hydrothermal reaction tower, the hydrothermal remains in the subcritical state, and the filling gas is nitrogen inert gas to get rid of the influence of oxygen on the hydrothermal reaction; The temperature of the thermal reaction tower is 230-250°C, the pressure is 5.0-6.0Mpa, and the residence time is 5min; the first liquid-phase stream, the first gas-phase stream and algae residue are obtained; wherein, the first liquid-phase stream includes an aqueous phase and an organic phase , the organic phase includes the hygrothermal decomposition substances of grease, protein, and carbohydrates and the water-insoluble organic matter generated by their mutual reactions; the water phase mainly includes subcritical water and aldehydes and amino acids dissolved in water; the first gas phase stream is ammonia , carbon dioxide and other small molecule gases, solid phase algae residues are deposite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com