Method for preparing water-based lithium cobaltate electrode plate from water soluble adhesive sodium alginate

A water-based lithium cobaltate and sodium alginate technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problem of low battery rate performance, achieve good electrochemical stability, good adhesive strength, and improve cycle stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

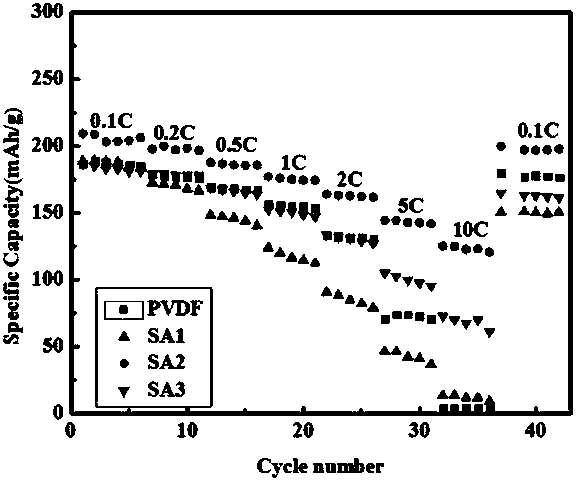

Embodiment 1

[0021] (1) Prepare a sodium alginate (SA) aqueous dispersion with a mass fraction of 2 wt%. First, weigh 2.744g of deionized water according to the calculation, add 0.056g of sodium alginate (SA) powder under stirring, and stir for about 2 hours until it is completely dissolved.

[0022] (2) Accurately weigh 3.16g of lithium cobalt oxide (LCO) and 0.05g of conductive carbon black (CB) in a mortar, grind them thoroughly to make them evenly mixed.

[0023] (3) Accurately weigh the above ground mixture, pour it into a beaker, and stir for 6 hours.

[0024] (4) Coat the above-mentioned uniformly stirred material on aluminum foil to form a film with a thickness of 100 μm, and then place it in a vacuum drying oven at 120°C for 12 h to obtain the code-named SA1 electrode. After rolling with a roller press, the circular electrode sheet with a diameter of 15 mm was made by pressing the sheet. The mass of the electrode sheet was accurately weighed with an analytical balance and the dat...

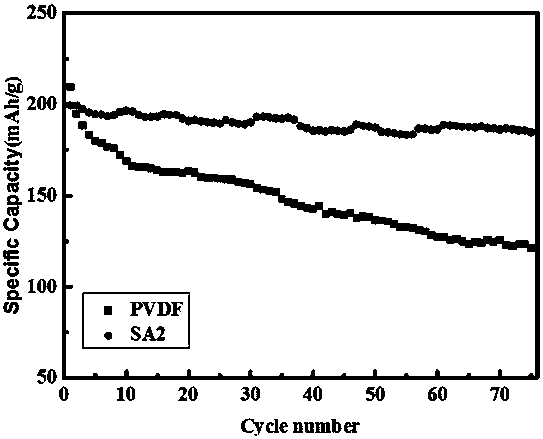

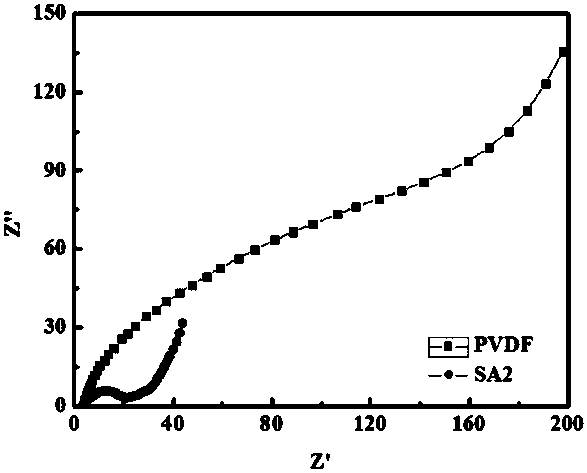

Embodiment 2

[0026] (1) Prepare a sodium alginate (SA) aqueous dispersion with a mass fraction of 2 wt%. First, weigh 1.96g of deionized water according to the calculation, add 0.04g of sodium alginate (SA) powder under stirring, and stir for about 2 hours until it is completely dissolved.

[0027] (2) Accurately weigh 1.62g of lithium cobaltate (LCO) and 0.153g of conductive carbon black (CB) in a mortar, grind them thoroughly to mix them evenly.

[0028] (3) Accurately weigh the above ground mixture, pour it into a beaker, and stir for 6 hours.

[0029] (4) Coat the above-mentioned uniformly stirred materials on aluminum foil to form a film with a thickness of 100 μm, and then place it in a vacuum drying oven at 120 °C for 12 h to obtain a code-named SA2 electrode. After rolling with a roller press, the circular electrode sheet with a diameter of 15 mm was made by pressing the sheet. The mass of the electrode sheet was accurately weighed with an analytical balance and the data was recor...

Embodiment 3

[0031] (1) Prepare a sodium alginate (SA) aqueous dispersion with a mass fraction of 2 wt%. First, weigh 2.45g of deionized water according to the calculation, add 0.05g of sodium alginate (SA) powder under stirring, and stir for about 2 hours until it is completely dissolved.

[0032] (2) Accurately weigh 1.62g of lithium cobaltate (LCO) and 0.153g of conductive carbon black (CB) in a mortar, grind them thoroughly to mix them evenly.

[0033](3) Accurately weigh the above ground mixture, pour it into a beaker, and stir for 6 hours.

[0034] (4) Coat the above-mentioned uniformly stirred materials on aluminum foil to form a film with a thickness of 100 μm, and then place it in a vacuum drying oven at 120 °C for 12 h to obtain a code-named SA3 electrode. After rolling with a roller press, the circular electrode sheet with a diameter of 15 mm was made by pressing the sheet. The mass of the electrode sheet was accurately weighed with an analytical balance and the data was record...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com