Double-spindle CNC engraving machine and its high-protection circular tool magazine

A round knife, high-protection technology, applied in the field of CNC machine tools, can solve the problems of limited machine travel, reduced spindle processing range, and inaccurate positioning, so as to reduce the in-position detection system, provide dust-proof performance, and reduce transmission. Institutional Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

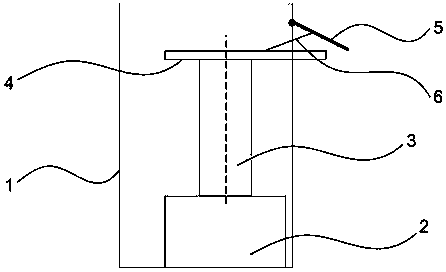

[0047] This embodiment provides a high-protection circular tool magazine, such as figure 1 As shown, it includes a base 2 accommodated in the shell 1 , a drive unit 3 and a cutter head 4 , and a tool storage door 5 arranged on the shell 1 . The drive unit 3 is installed on the base 2 and drives the cutterhead 4 to rotate. The upper edge of the tool magazine door 5 is fixed on the shell cover 1 through a hinge. The cutterhead 4 is D-shaped, and its contour is composed of a circular arc part and a straight line part, and a plurality of cutters are located in the circular arc part. The cutterhead 4 is connected with the knife magazine door 5 through the connecting rod 6, and the two ends of the connecting rod 6 are respectively connected with the cutterhead 4 and the knife magazine door 5 at appropriate positions; Close the magazine door 5.

Embodiment 2

[0049] This embodiment provides another high-protection circular tool magazine, such as figure 2 and 3 As shown, it includes a base 2 accommodated in the shell 1 , a drive unit 3 and a cutter head 4 , and a tool storage door 5 arranged on the shell 1 . The driving unit 3 is installed on the base 2 and drives the cutter head 4 and the lifting wheel 7 to rotate. The upper edge of the tool magazine door 5 is fixed on the shell cover 1 through a hinge. The upper side of the knife magazine door 5 is equipped with a collision bar 8 inside the super shell cover.

[0050] Cutterhead 4 and lifting wheel 7 are all D-shaped, and its profile is as Figure 5 As shown, its profile is composed of a circular arc part and a straight line part, and multiple cutters are located on the circular arc part of the cutter head 4, such as Figure 4 and Figure 8 shown.

[0051] like Figure 5 As shown, the straight part of the lifting wheel can be provided with an inclined surface, so that the ...

Embodiment 3

[0057] The profile of the lifting wheel can also be made up of two sections of circular arcs with different radii, wherein the larger circular arc replaces the straight line part of the lifting wheel in embodiment 2, such as Image 6 As shown, the lifting wheel on the left side of the figure is the lifting wheel of this embodiment, and the right side is the lifting wheel of embodiment 2. According to the design of this embodiment, the meshing process between the profile of the lifting wheel and the strike bar is smoother.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com