Manufacturing method of powder materials for additive manufacturing

A technology of additive manufacturing and manufacturing methods, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of difficulty in promoting additive manufacturing technology, inability to meet the requirements of teaching, trial production or low-end parts, and high cost. Achieve the effect of shortening the solidification time, improving the atomization efficiency and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

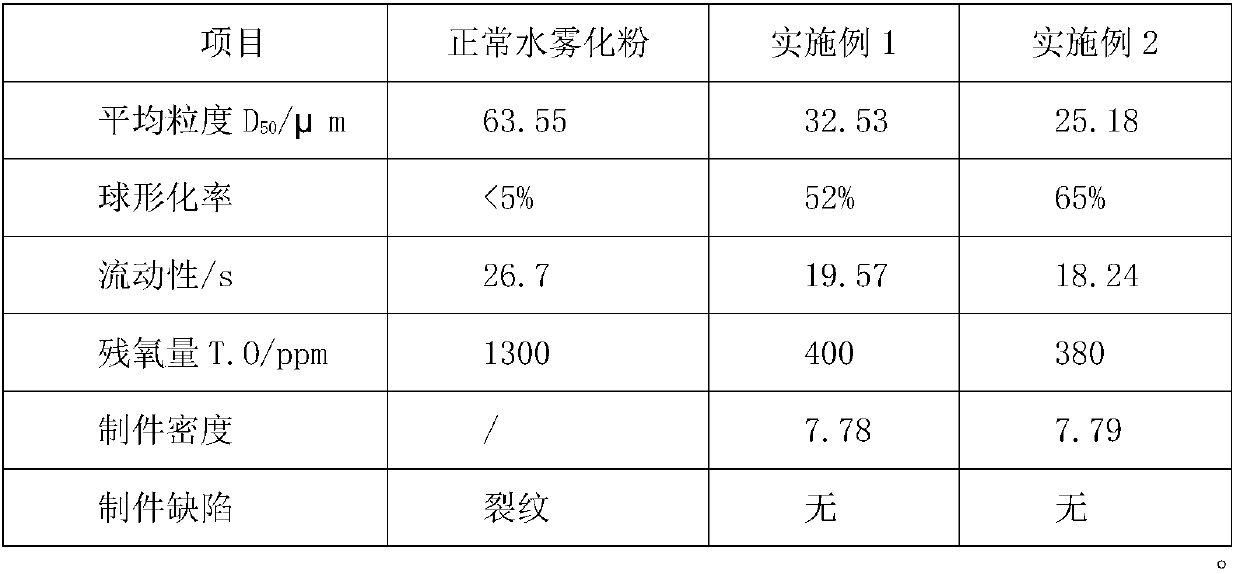

Embodiment 1

[0031] The normally produced iron powder is sieved to 1000 mesh, and the -1000 mesh iron powder produced is injected into the atomized water through compressed air as raw material. The molten iron with uniform and stable composition and less impurities can be obtained by smelting. The superheat of the molten iron is 260°C, the diameter of the liquid flow is 4-6mm; the pressure of the high-pressure airflow is 0.5Mpa, and the air flow rate is 3.5m 3 / min, high-pressure water atomization pressure is 115-120Mpa, flow rate is 180-200m 3 / min. The flow rate of -1000 mesh iron powder is 65g / s, the reducing gas is hydrogen, the reducing temperature is 450°C, and the reducing time is 40min. Grind and sieve the powder material of -100+300 mesh, adopt the coaxial powder feeding printing process, the laser power is 2000W, the spot diameter is 3mm, the scanning speed is 900mm / min, and the powder feeding volume is 2.5 rpm. The sorted -1000 mesh iron powder is used as the core particle for...

Embodiment 2

[0033] The normal production steel powder is sieved to 1000 mesh, and the -1000 mesh steel powder produced is injected into the atomized water through compressed air as raw material. The molten steel with uniform and stable composition and less impurities can be obtained by smelting. The superheat of molten steel is 260°C, the diameter of liquid flow is 4-6mm; the pressure of high-pressure airflow is 0.7Mpa, and the air flow rate is 3.5m 3 / min, high-pressure water atomization pressure is 115-120Mpa, flow rate is 180-200m 3 / min. The flow rate of -1000 mesh steel powder is 90g / s, the reducing gas is hydrogen, the reducing temperature is 450°C, and the reducing time is 50min. Grind and sieve powder materials of -300+1000 mesh, use the laser selection printing process with a laser power of 500W, and a scanning speed of 500mm / min. The sorted -1000 mesh iron powder is used as the core particle for the next smelting and is transported to the atomizer through high-pressure airflow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com