Oily grinding liquid and preparation method thereof

An abrasive liquid and oil-based technology, which is applied in chemical instruments and methods, polishing compositions containing abrasives, and other chemical processes, can solve the problems of high temperature, poor dispersion, and large TTV of the abrasive disc, and achieve a stable disc temperature. control, high grinding rate and small TTV

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

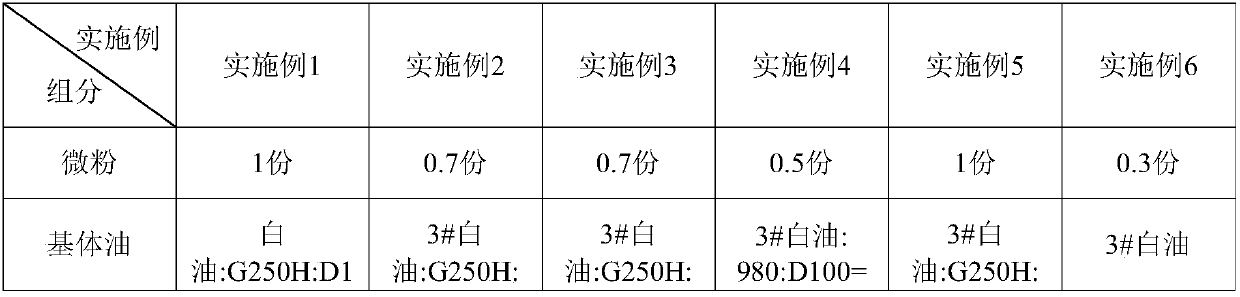

[0048] The formula of concrete oily diamond grinding liquid is as shown in table 1 below (parts are mass parts):

[0049] Table 1 Proportion Table of Oily Grinding Fluid

[0050]

[0051]

[0052] The concrete preparation method of above-mentioned embodiment is:

[0053] Under the conditions of a stirring speed of 300rpm and a reaction temperature of 30°C, the diamond powder with a median particle size of 6μm, a surfactant, and a base oil were mixed, stirred ultrasonically for 5-10 minutes, and then modified on the surface, and then added For wet dispersant and suspending agent, continue ultrasonic stirring for 5-10 minutes to ensure that the diamond powder is fully and evenly dispersed in the mixed solution, add lubricant and anti-wear agent to the above mixed solution in proportion, and ultrasonically stir for 5-10 minutes. The tester tests the mixture obtained above, and according to the actual viscosity of the test, add a proper amount of viscosity modifier (viscosi...

Embodiment 7-12

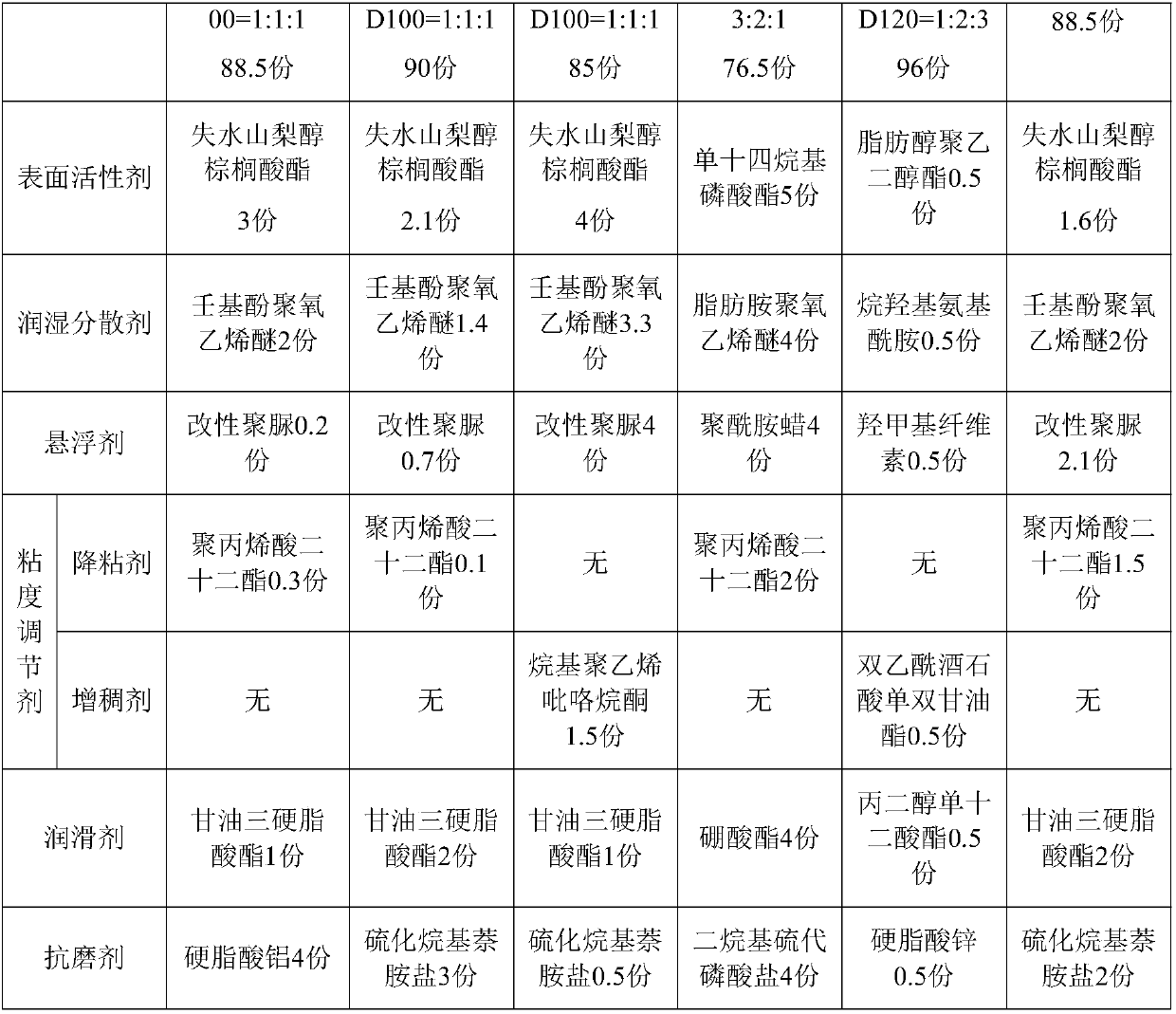

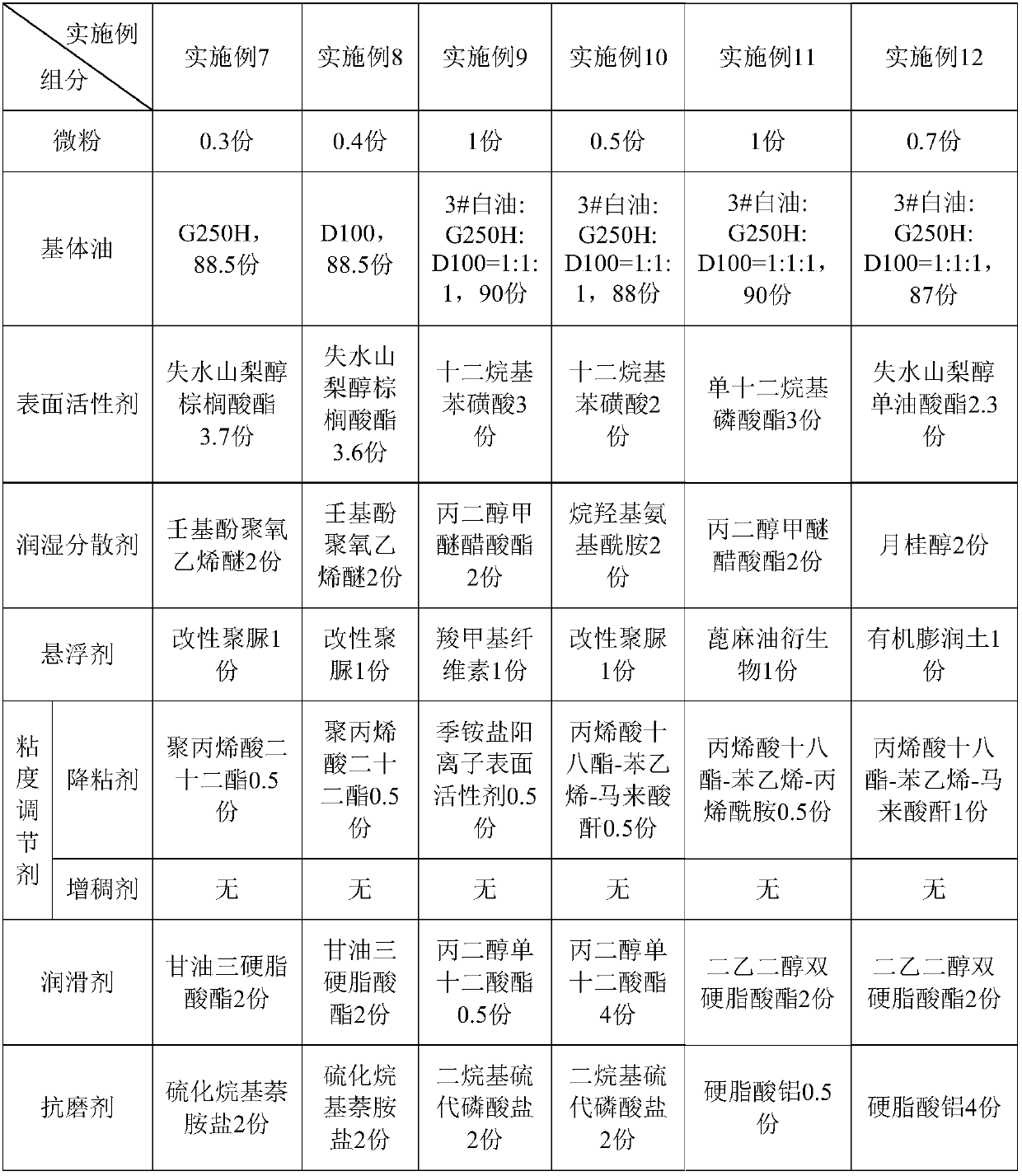

[0055] The formula of concrete oily diamond grinding liquid is as shown in table 2 below (parts are mass parts):

[0056] Table 2 Proportion Table of Oily Grinding Fluid

[0057]

[0058] The concrete preparation method of above-mentioned embodiment is:

[0059] Under the conditions of a stirring speed of 100rpm and a reaction temperature of 20°C, mix diamond micropowder with a median particle size of 6μm, a surfactant, and base oil, and ultrasonically stir for 5-10 minutes to carry out surface modification; then add a wetting and dispersing agent, suspending agent, ultrasonically stirred for 5-10 minutes to ensure that the diamond powder is fully and evenly dispersed in the mixed solution, and the lubricant and anti-wear agent are added to the above mixed solution in proportion, and ultrasonically dispersed for 5-10 minutes while stirring. The tester tests the mixture obtained above, and according to the actual viscosity of the test, add an appropriate amount of viscosity...

Embodiment 13

[0061] The specific formula is the same as in Example 1, except that the viscosity reducer is increased from 0.3 parts to 2 parts. The specific preparation method is: mixing diamond micropowder, surfactant, and base oil with a median particle size of 6 μm at 200 rpm, stirring at 25 ° C for 5- 10min, carry out surface modification; then add wetting and dispersing agent, suspending agent 200rpm, 25°C and stir for 5-10min to ensure that the diamond powder is fully and evenly dispersed in the mixture, and add lubricant and antiwear agent to the above mixture in proportion In the solution, 200rpm, 25 ℃ while stirring and ultrasonic dispersion for 5-10min, use the viscosity tester to test the above-mentioned mixed solution, and according to the actual viscosity of the test, add a proper amount of viscosity modifier (viscosity reducer, thickener or no addition ), 100rpm, 25°C stirring and ultrasonic dispersion for 3-5min, so that the final viscosity of the mixed solution is controlled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com