Two-cycle aviation heavy oil piston engine cylinder sleeve inner wall laser micro-texturing structure

A technology of engine cylinder and micro-modelling, which is applied in the direction of engine components, machines/engines, pistons, etc. It can solve the problems that the lines cannot be adjusted according to the needs, and the independent pits cannot be processed, etc., and achieve small linear expansion coefficient, heat resistance and Good casting performance and improved sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

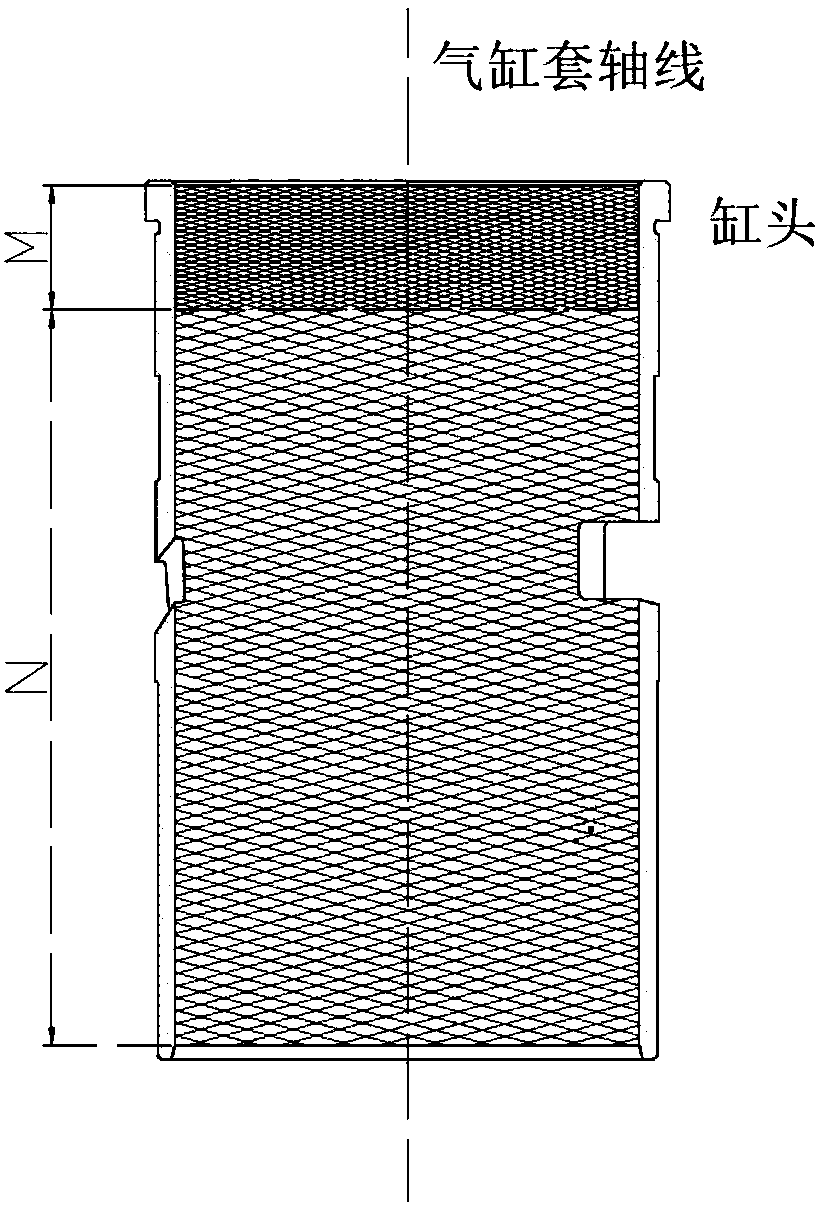

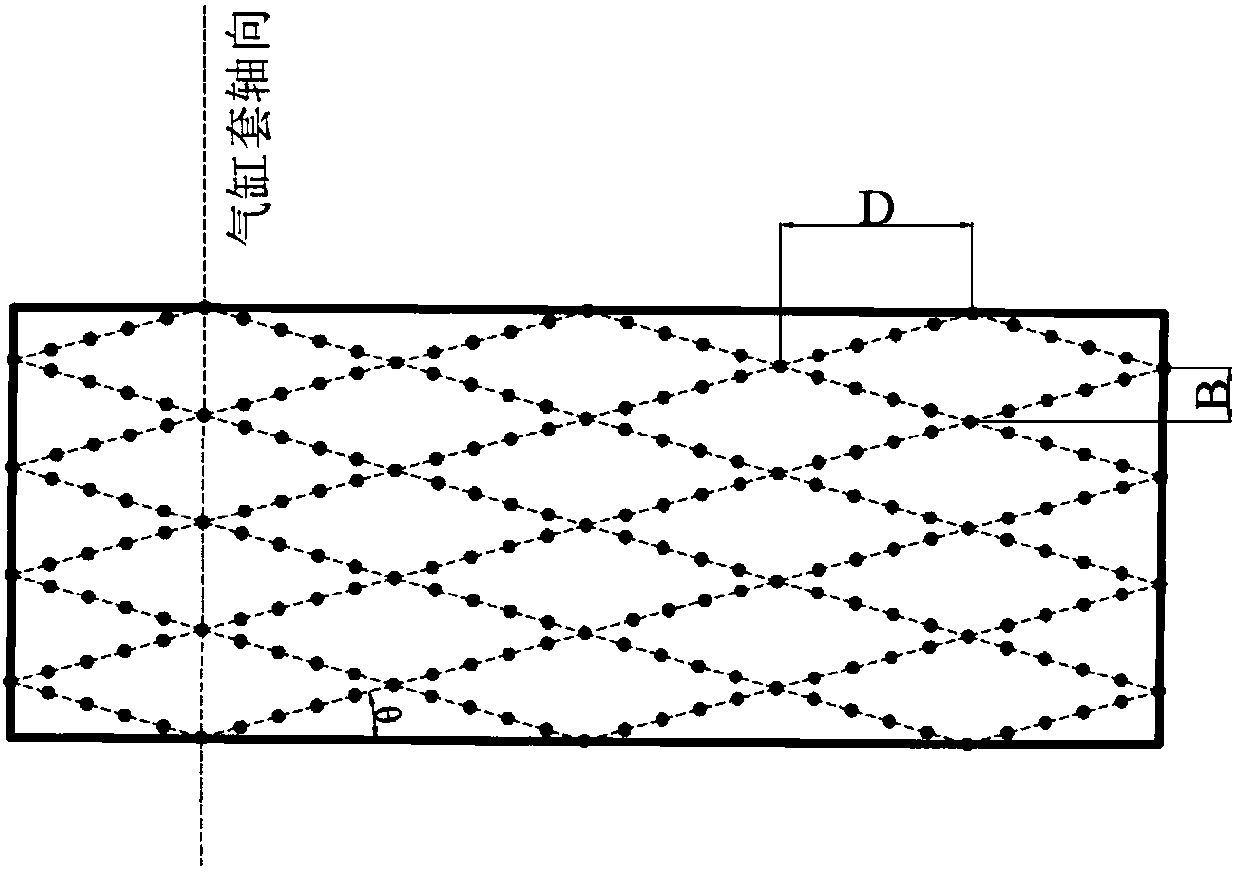

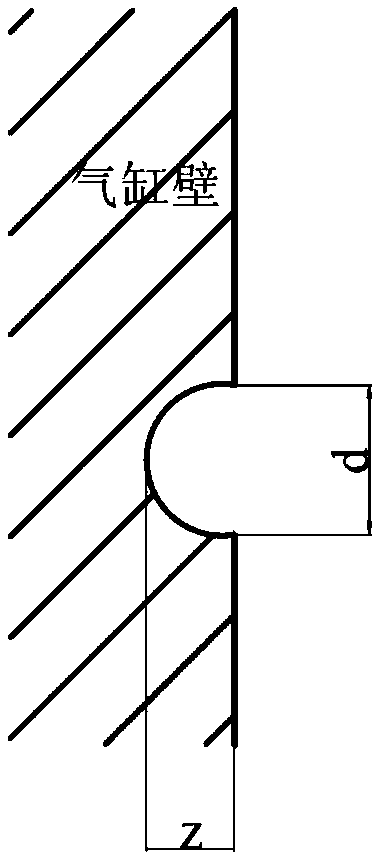

[0055] Such as figure 1 As shown in -2, the laser micro-modeling structure of the inner wall of the engine cylinder liner disclosed by the present invention, the cylinder includes the M area of the cylinder liner head and the N area of the cylinder block. Sparse micro-modeling; the micro-modeling adopts a spiral pattern with a small inclination relative to the plane perpendicular to the axial direction of the cylinder. The pits are mesh points, and there are multiple pits between adjacent mesh points. The angle θ between the lines and the axial direction of the cylinder, that is, the cylinder circumferential direction, is between 10°-15°. The vertical distance B of the pattern point in the axial direction of the cylinder liner is 1-1.3mm, the vertical distance D of the adjacent pattern point in the cylinder liner circumferential direction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pit depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com