A kind of titanium ruthenium co-doped vanadium dioxide thermosensitive thin film material and preparation method thereof

A vanadium dioxide heat-sensitive, vanadium oxide thin film technology, applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problem of limiting the selection of device working parameters, restricting the design of pixel structure, and reducing the signal-to-noise ratio To achieve the effect of flexible pixel structure design and device working parameter selection, avoiding adverse effects, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

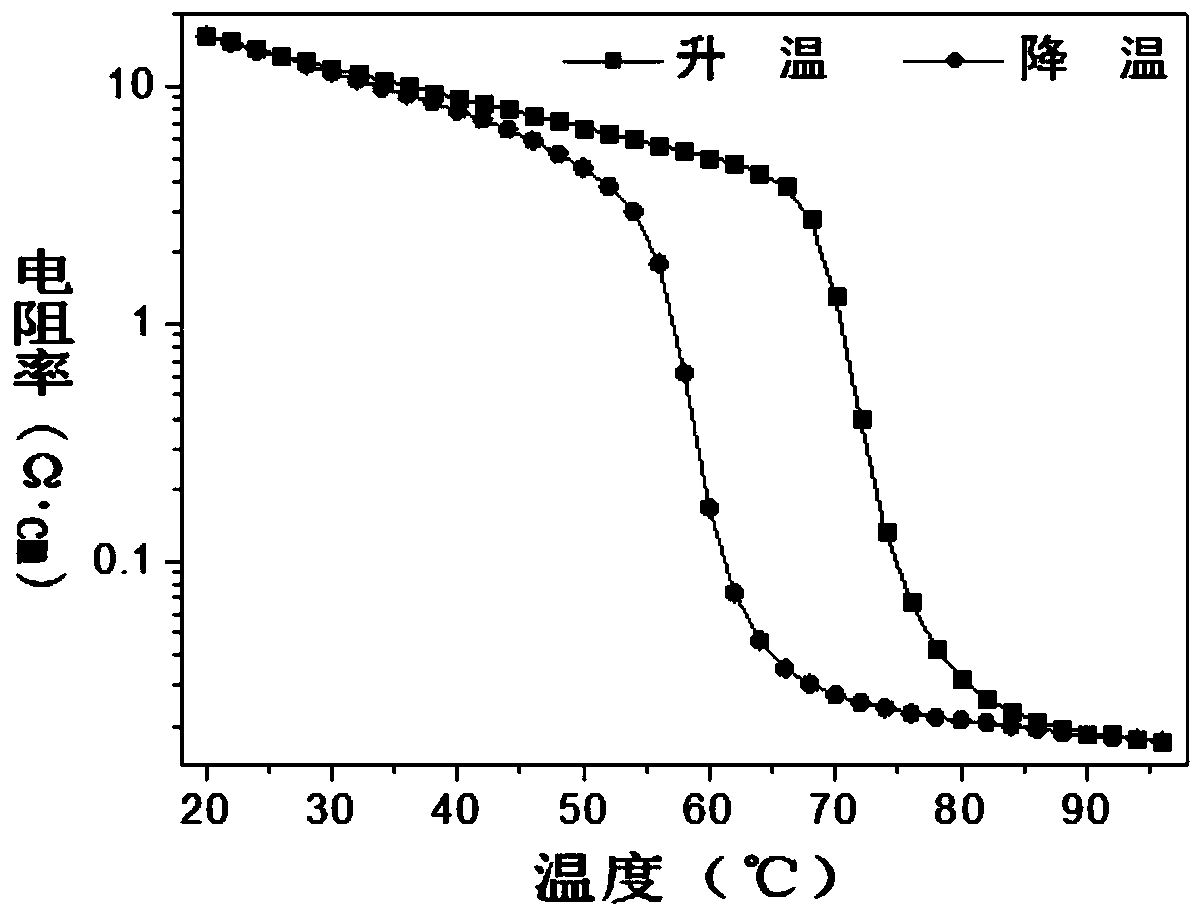

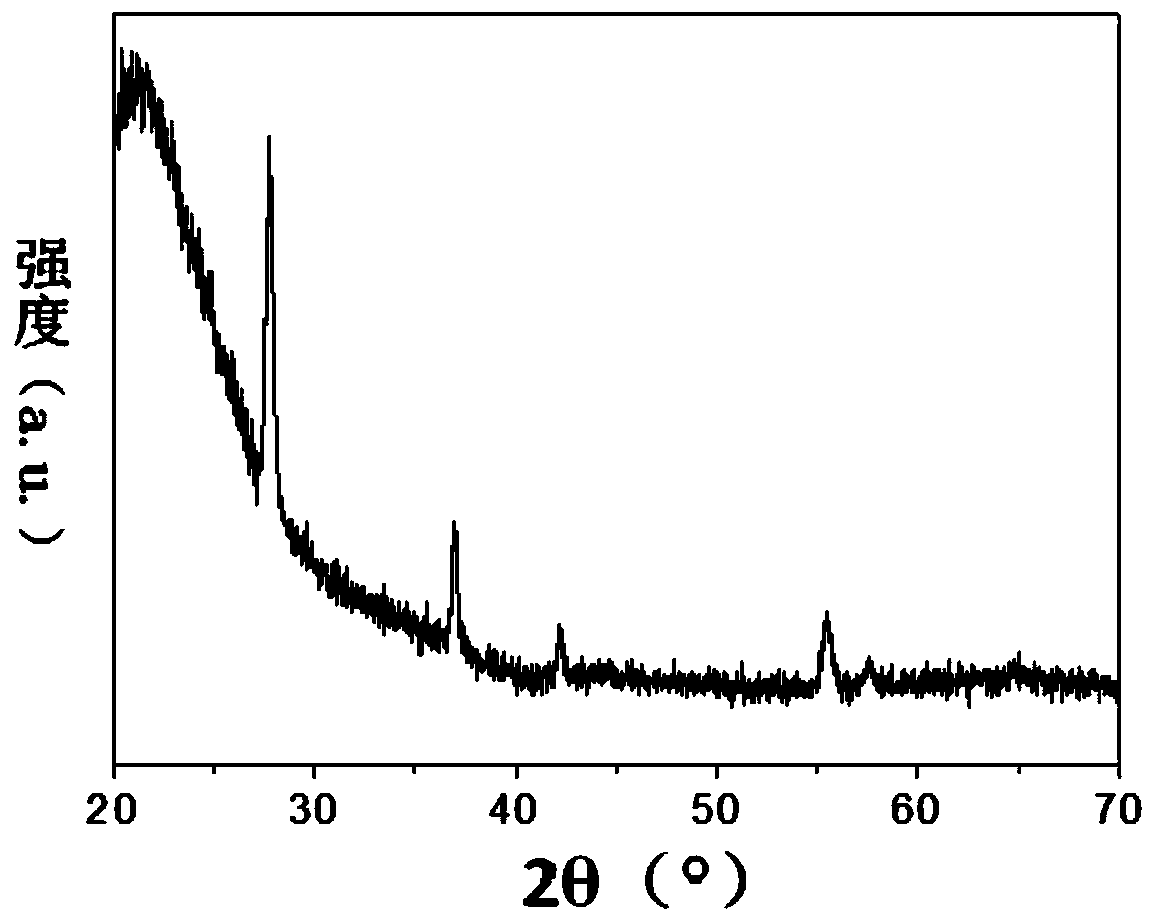

[0046] Embodiment 1.1 (comparative example):

[0047] Will come with 250nmSiN X The thin film Si wafer was preheated at 100°C for 40 minutes in the vacuum environment of the sputtering chamber; then the pure vanadium target (99.9%) was used as the sputtering source, and the pure vanadium The target was pre-sputtered for 5 minutes; then, using an atmosphere with an oxygen / argon flow ratio of 1:20, and at a working pressure of 1.5Pa, the preheated substrate (with 250nm SiN X The vanadium oxide thin film was sputter-deposited on the thin film Si sheet) for 50 minutes; and then under the oxygen-enriched atmosphere with an oxygen / argon flow ratio of 10:1, and at a vacuum chamber pressure of 1.5 Pa, the enrichment was carried out at 380°C for 60 minutes. Oxygen atmosphere annealing. After the annealing is completed, the temperature is lowered to below 85° C., and the sample is taken out to obtain an undoped vanadium dioxide film (referred to as VO-11). This sample is used as a com...

Embodiment 12

[0054] Will come with 250nmSiN X The thin-film Si sheet was preheated at 120°C for 60 minutes in the vacuum environment of the sputtering chamber; then, the titanium-ruthenium-vanadium alloy target containing 6.0% titanium and 1.0% ruthenium (atomic percentage) was used in a pure argon atmosphere at 0.5Pa Under the working pressure, the titanium ruthenium vanadium alloy target was pre-sputtered for 15 minutes; then, the oxygen / argon flow ratio was 1:30, and the titanium ruthenium vanadium alloy target was sputtered under the working pressure of 2.5Pa. After the substrate (with 250nmSiN X Ti-Ru co-doped vanadium oxide thin film was deposited on the thin film Si sheet) for 50 minutes; and then under the oxygen-enriched atmosphere with the oxygen / argon flow ratio of 1:0, under the vacuum chamber pressure of 1.0Pa, carry out 350 ℃, 90 minutes Annealed in an oxygen-enriched atmosphere. After the annealing is completed, the temperature is lowered to below 85° C., and the sample is...

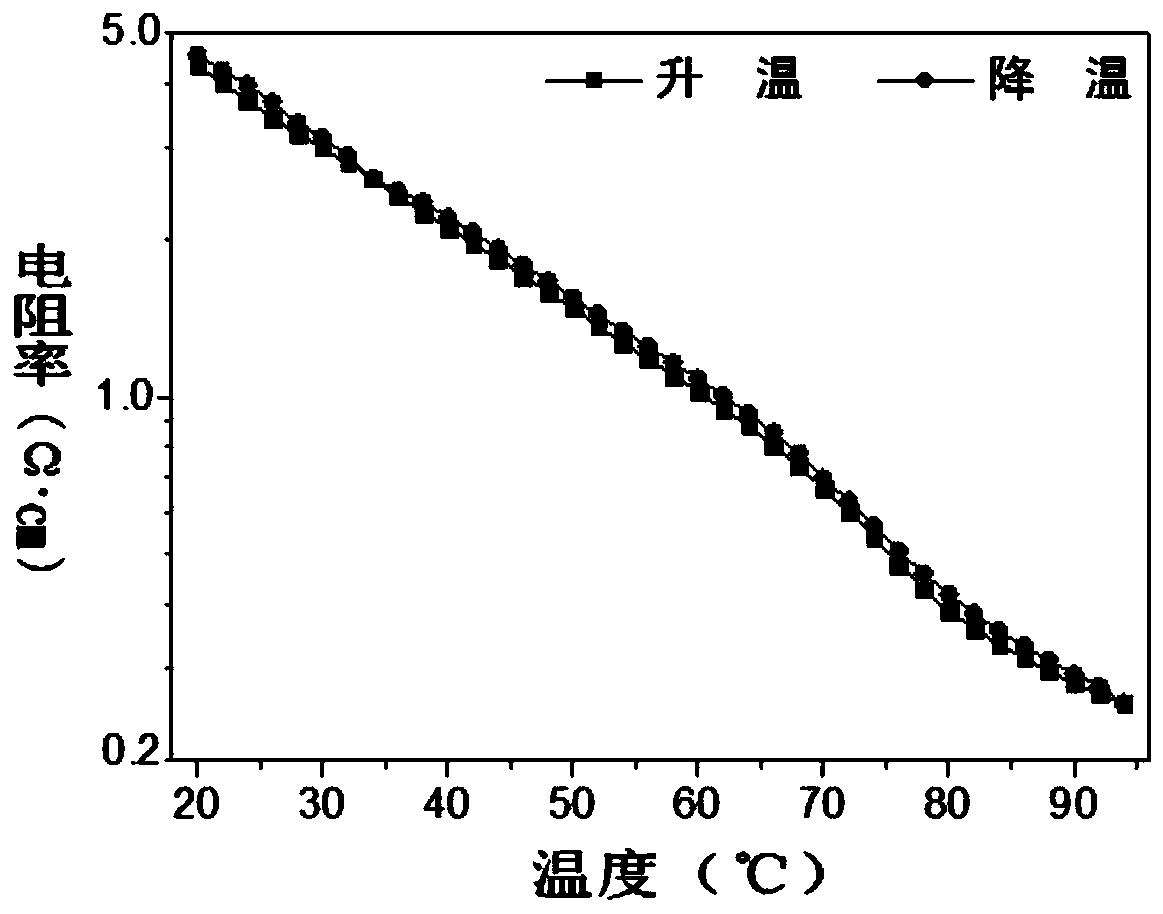

Embodiment 13

[0061] will come with 250nmSiO 2 The thin-film Si sheet was preheated at 100°C for 100 minutes in the vacuum environment of the sputtering chamber; then, a titanium-ruthenium-vanadium alloy target containing 7.5% titanium and 2.0% ruthenium (atomic percentage) was used in a pure argon atmosphere at 1.0Pa Under the working pressure, the titanium ruthenium vanadium alloy target was pre-sputtered for 10 minutes; then, the oxygen / argon flow ratio was 1:25, and the titanium ruthenium vanadium alloy target was sputtered under the working pressure of 2.0Pa. Deposit titanium ruthenium co-doped vanadium oxide thin film on the substrate after 50 minutes; then carry out 350 ℃, 90 minutes oxygen-enrichment atmosphere under the oxygen-enrichment atmosphere of 2:1 oxygen / argon flow ratio, under the vacuum chamber pressure of 3.0Pa Atmosphere annealing. After the annealing is completed, the temperature is lowered to below 85° C., and the sample is taken out to obtain a titanium-ruthenium co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com