Manufacturing method for front substrate of plasma display screen

A technology for plasma display screens and manufacturing methods, which is applied in the field of manufacturing front substrates in plasma display screens, can solve problems such as high cost, achieve the effects of reducing ignition voltage, reducing costs, and ensuring aperture ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

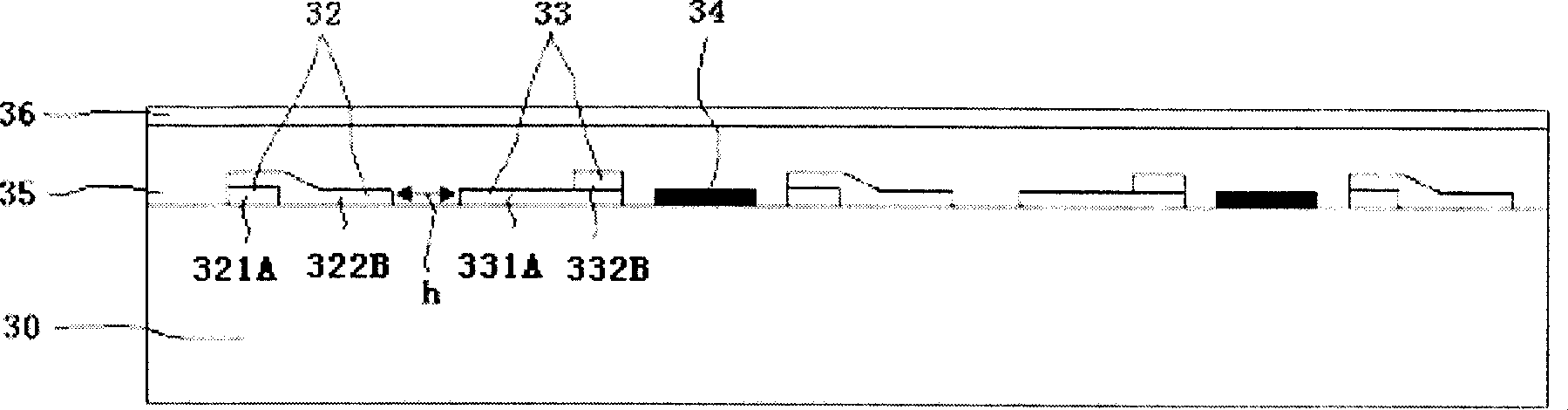

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0031] The preparation method of the front substrate of the plasma display screen of the present invention is carried out according to the following steps:

[0032] Firstly, the transparent electrodes are omitted, and bus electrodes with holes or T-shaped bus electrodes are used, and the electrode patterns of the bus electrodes with holes or T-shaped bus electrodes are photo-etched on the front glass substrate 30;

[0033] When a perforated bus electrode is used

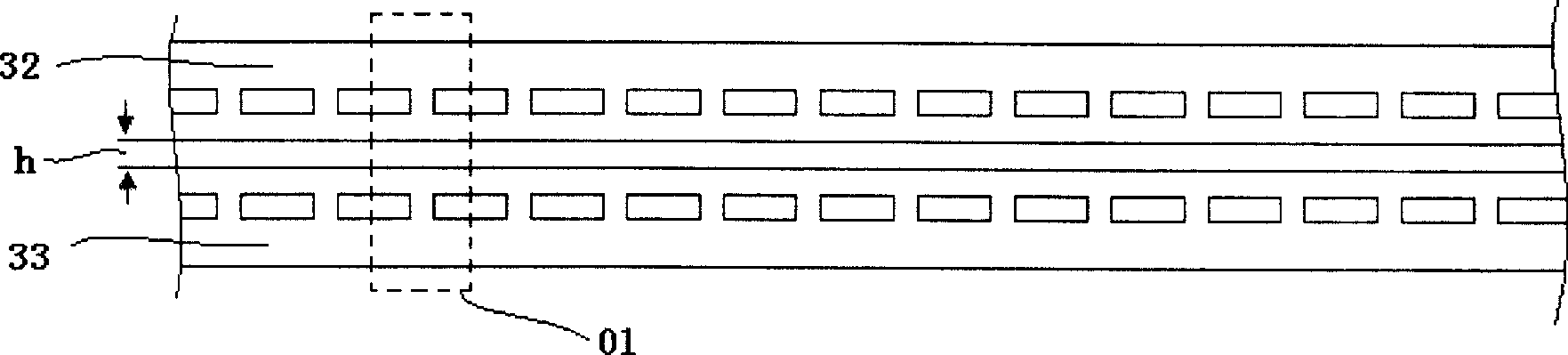

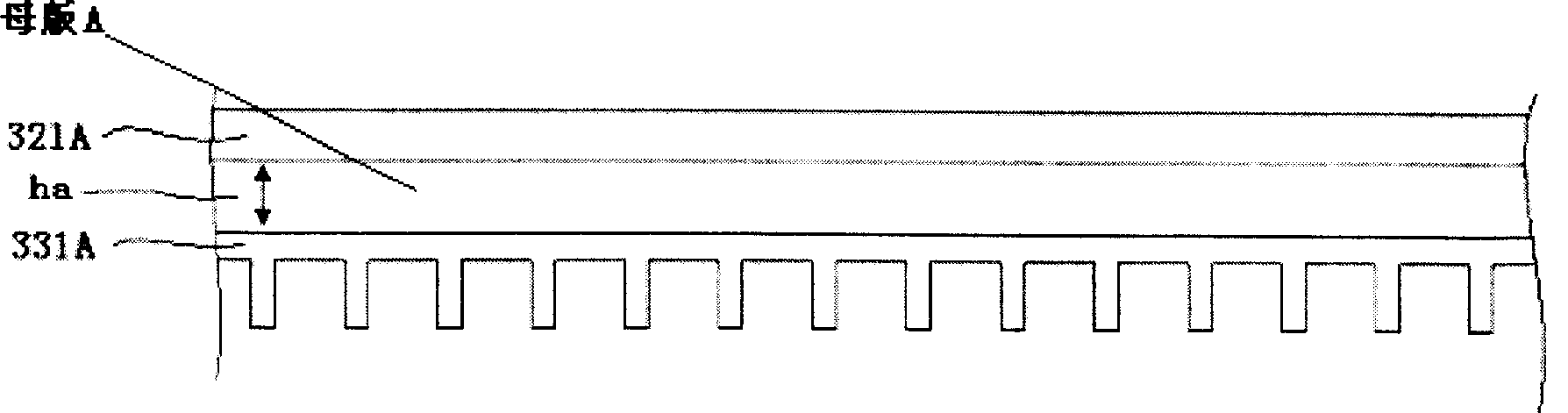

[0034] Firstly, the annealed front glass substrate 30 is cleaned, printed with photosensitive paste, dried, exposed with the motherboard A carrying the decomposed bus electrode pattern, and then developed and fired. The electrode pattern of the motherboard A is composed of The rectangular perforated bus x-electrode 321A pattern and the zigzag perforated bus y-electrode 331A pattern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com