Packaging structure and packing method of organic light-emitting diode as well as display device

A technology of light-emitting diodes and packaging structures, which is applied in the direction of organic semiconductor devices, electrical components, and electric solid-state devices. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0029] Inorganic films are mainly water and oxygen barrier layers, but they have low elasticity and large internal stress, so flexible packaging cannot be realized. Organic polymers have high elasticity, which can inhibit the cracking of inorganic films and release the stress between inorganic substances. The combination of the two can achieve A flexible packaging method.

[0030] The organic light emitting diode packaging structure in the embodiment of the present invention is based on the above flexible packaging method to realize flexible packaging.

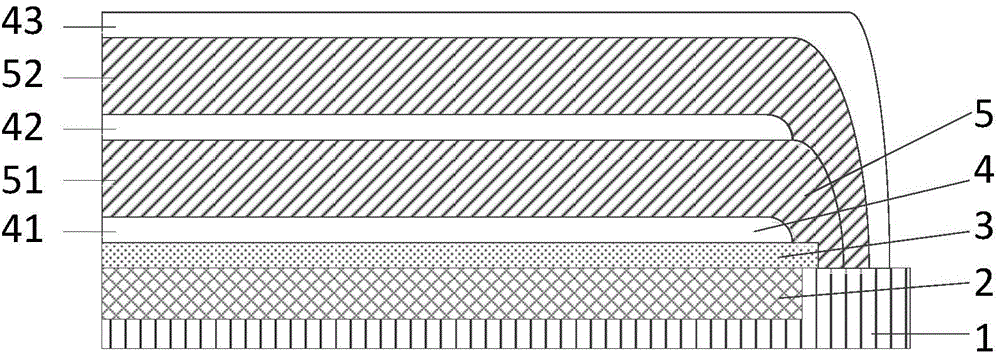

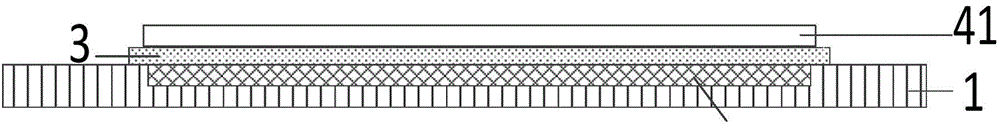

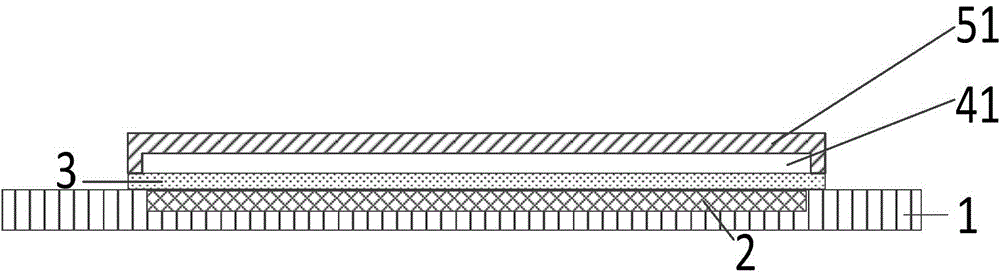

[0031] figure 1 It shows a schematic structural diagram of an organic light emitting diode packaging structure provided b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com