Special ABS material for storage battery case

A technology of ABS material and battery, applied in the field of ABS material, can solve the problem of easy rupture of the shell, and achieve the effects of improving corrosion resistance and heat resistance, improving flame retardant performance and good flame retardant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

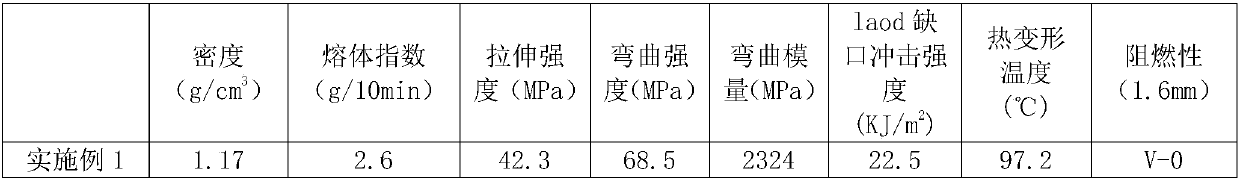

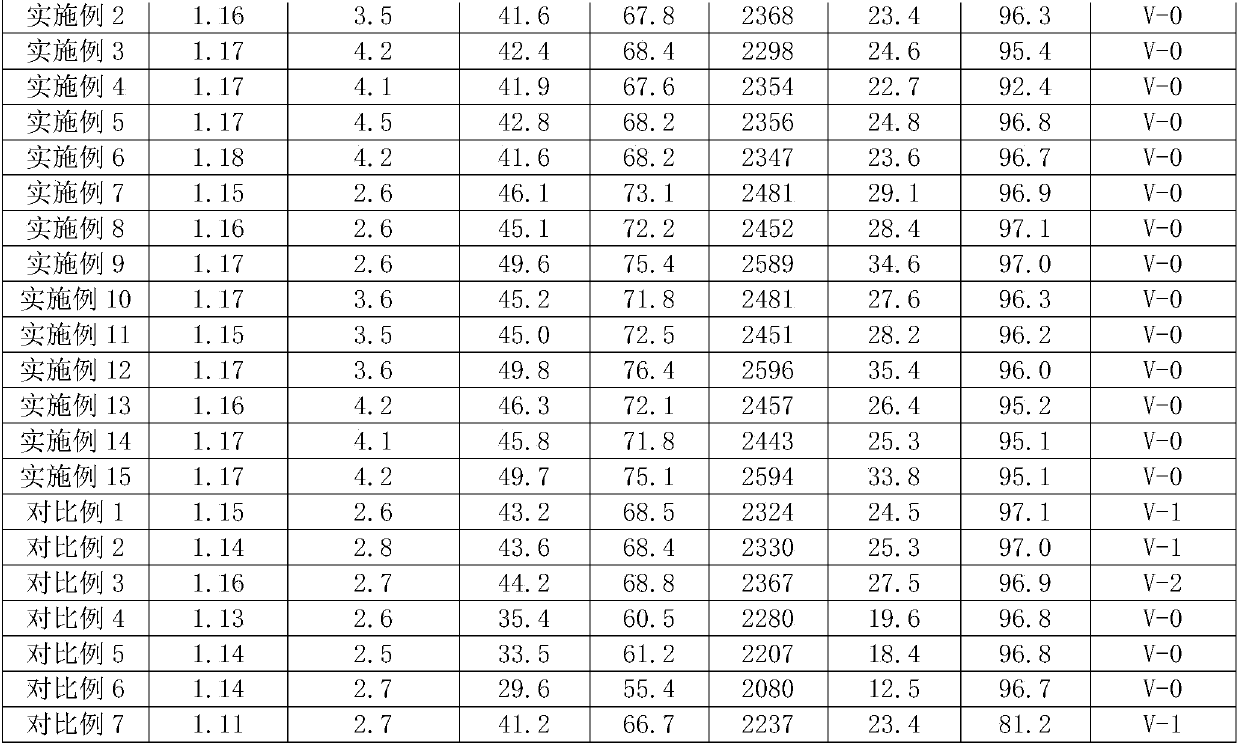

Examples

Embodiment 1

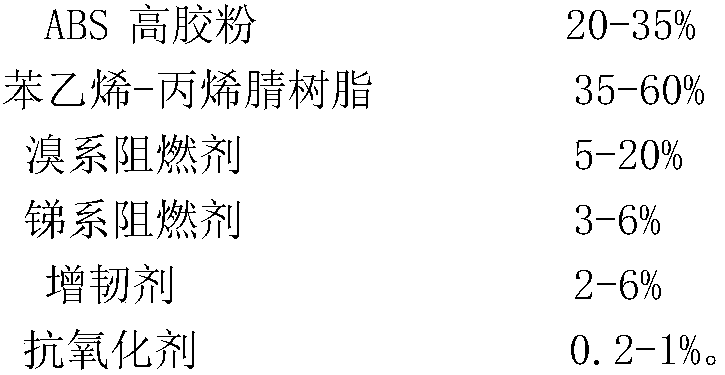

[0027] Embodiment 1: A special ABS material for battery casing, each component and mass fraction in the raw material are as shown in Table 1, wherein, the content of acrylonitrile in the styrene-acrylonitrile resin is 5% of the content of the styrene-acrylonitrile resin 25%-35%, the melt index of styrene-acrylonitrile resin under the test condition of 200℃×5kg is 2.5g / 10min, the brominated flame retardant is brominated epoxy resin, and the antimony-based flame retardant is trioxide Diantimony, the toughening agent is powdered nitrile rubber, and the antioxidant is tetrakis [β-(3,5 di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester.

[0028] The manufacturing process of the ABS material specially used for battery shells, according to the proportions of the components in Table 1, weighed the components of the formula amount, added them to the high-speed mixer and mixed them evenly, then sent them into the twin-screw extruder, and the twin-screw extruder The tempera...

Embodiment 2

[0029] Example 2: A special ABS material for battery casings. The difference from Example 1 is that the components and mass fractions in the raw materials are shown in Table 1. Among them, the ABS high rubber powder has a rubber content of 50-65%, the antimony-based flame retardant is antimony pentoxide, and the antioxidant is β-(-4-hydroxy-3,5-di-tert-butylphenyl)propionic acid n- Octadecyl ester, the processing aid is ethylene bis stearamide.

Embodiment 3

[0030] Embodiment 3: A special ABS material for battery casings. The difference from Embodiment 1 is that the components and mass fractions in the raw materials are shown in Table 1. Wherein, the antimony-based flame retardant is sodium antimonate, the antioxidant is tris(2,4-di-tert-butylphenyl) phosphite, and the processing aid is magnesium stearate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com