Lithium ion battery negative electrode material and preparation method

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc., can solve the problems of large volume expansion and low electronic conductivity of molybdenum disulfide, and achieve high Effect of rate performance, excellent cycle performance and rate performance, long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

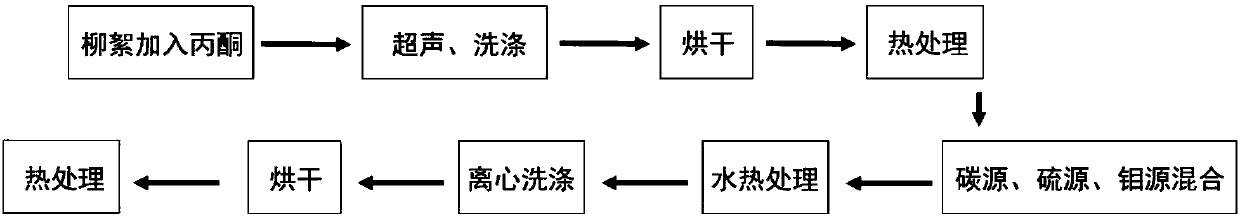

[0031] Such as figure 1 As shown, the preparation method of a kind of negative electrode material of lithium ion battery that the embodiment of the present invention provides, comprises:

[0032] (1) Dissolve the molybdenum source and the sulfur source of a certain molar ratio in deionized water, stir evenly, and form a clear solution; wherein, the concentration of the molybdenum source is 8 × 10 -3 ~2×10 -1 mol / L, the concentration of the sulfur source is 1.6×10 -2 ~1mol / L;

[0033] (2) adding catkins to acetone for ultrasonic treatment; then placing catkins in deionized water for vigorous stirring and washing; then drying in vacuum; sending the catkins after pretreatment into a tube furnace, and heat-treating catkins at a certain temperature for 1-3 hours to obtain catkins Derived hollow carbon microtubes; the catkin-derived hollow carbon microtubes are dispersed in the clarified solution obtained in step 1) to form a uniform suspension;

[0034] (3) adding the uniform s...

Embodiment 1

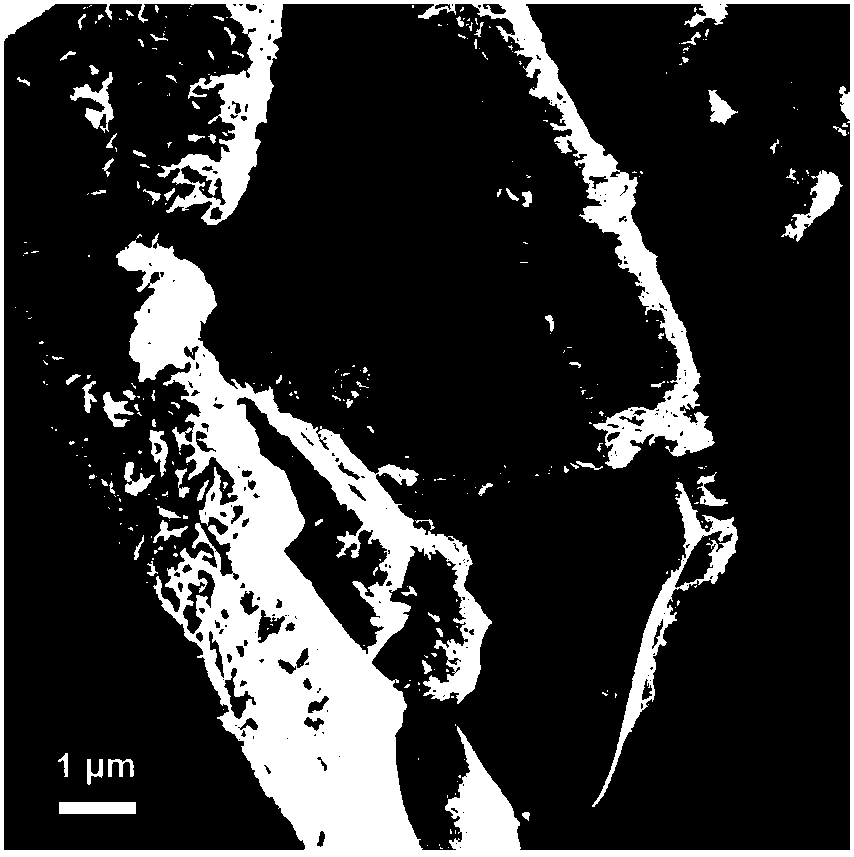

[0042] Weigh 0.304g of sodium molybdate dihydrate and dissolve 0.947g of thiourea in 20mL of deionized water, and stir evenly to obtain a clear solution. The pretreated catkins were sent into a tube furnace, and then heat-treated at 800° C. for 1 hour in an argon atmosphere to obtain catkin-derived hollow carbon microtubes. Then 0.030 g of catkin-derived hollow carbon microtubes was weighed and added to the above clarified solution to form a uniform suspension. Then the obtained homogeneous suspension was poured into a 50ml stainless steel hydrothermal kettle lined with polytetrafluoroethylene, and reacted at 200°C for 24h. The precursor obtained by the reaction was washed with deionized water and ethanol respectively, and dried under vacuum at 80° C. for 12 h. Put the precursor in a crucible, set the temperature at 800°C under an argon atmosphere, and heat-treat for 1 hour. After the reaction, cool with the furnace to obtain MoS 2 / Catkin-derived hollow carbon microtube co...

Embodiment 2

[0044] Weigh 0.706g of ammonium molybdate tetrahydrate and dissolve 1.503g of thioacetamide in 20mL of deionized water, and stir evenly to obtain a clear solution. The pretreated catkins were sent into a tube furnace, and heat-treated at 500° C. for 3 hours in an argon atmosphere to obtain catkin-derived hollow carbon microtubes. Then 0.060 g of catkin-derived hollow carbon microtubes was weighed and added to the above clarified solution to form a uniform suspension. Then the obtained homogeneous suspension was poured into a 50ml stainless steel hydrothermal kettle lined with polytetrafluoroethylene, and reacted at 240°C for 12h. The precursor obtained by the reaction was washed with deionized water and ethanol respectively, and dried under vacuum at 80° C. for 12 h. Put the precursor in a crucible, set the temperature at 500°C under a nitrogen atmosphere, and heat-treat for 3 hours. After the reaction, cool with the furnace to obtain MoS 2 / Catkin-derived hollow carbon mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com