Gold extraction agent and preparation process thereof

A technology of gold extracting agent and sodium carbonate, which is applied in the field of gold extracting agent and its preparation process, can solve the problems of high production cost, high toxicity, complex formula, etc., and achieve high stability, high gold extraction rate and high stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

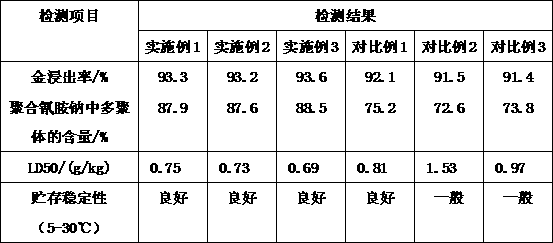

Examples

Embodiment 1

[0017] Embodiment 1: preparation extracts gold agent

[0018] The formula is: a gold extracting agent, the gold extracting agent is mainly composed of urea, sodium carbonate, sodium ferrocyanide, and sodium thiosulfate, and the ratio of parts by weight of urea, sodium carbonate, and sodium ferrocyanide is: 50 :25:5.

[0019] The preparation method is: a preparation method of a gold extracting agent, comprising the following steps: (1) Weighing urea, sodium carbonate, and sodium ferrocyanide, adding the urea, sodium carbonate, and sodium ferrocyanide to a crusher for crushing, Obtain mixed particles with a particle size of 0.05mm; (2) Mix and stir the mixed particles for 5 minutes; (3) Put the mixed particles into the reactor for 5 minutes and react at a reaction temperature of 500°C, and the waste gas generated by the reaction is recycled with sodium hydroxide solution , the concentration of the sodium hydroxide solution is 0.5mol / L; (4) Liquid-solid separation is performed i...

Embodiment 2

[0020] Embodiment 2: preparation extracts gold agent

[0021] The formula is: a gold extracting agent, the gold extracting agent is mainly composed of urea, sodium carbonate, sodium ferrocyanide, and sodium thiosulfate, and the ratio of parts by weight of urea, sodium carbonate, and sodium ferrocyanide is: 70 :40:10.

[0022] The preparation method is: a preparation method of a gold extracting agent, comprising the following steps: (1) Weighing urea, sodium carbonate, and sodium ferrocyanide, adding the urea, sodium carbonate, and sodium ferrocyanide to a crusher for crushing, Obtain mixed particles with a particle size of 1.50 mm; (2) Mix and stir the mixed particles for 15 minutes; (3) Put the mixed particles into the reactor for 15 minutes and react at a reaction temperature of 700 ° C. The waste gas generated by the reaction is recycled with sodium hydroxide solution , the concentration of the sodium hydroxide solution is 1.0mol / L; (4) Liquid-solid separation is performed...

Embodiment 3

[0023] Embodiment 3: preparation extracts gold agent

[0024] The formula is: a gold extracting agent, the gold extracting agent is mainly composed of urea, sodium carbonate, sodium ferrocyanide, and sodium thiosulfate, and the ratio of parts by weight of urea, sodium carbonate, and sodium ferrocyanide is: 60 :30:7.

[0025] The preparation method is: a preparation method of a gold extracting agent, comprising the following steps: (1) Weighing urea, sodium carbonate, and sodium ferrocyanide, adding the urea, sodium carbonate, and sodium ferrocyanide to a crusher for crushing, Obtain mixed particles with a particle size range of 0.10 mm; (2) Mix and stir the mixed particles for 10 minutes; (3) Put the mixed particles into the reactor for 10 minutes of reaction, the reaction temperature is 600 ° C, and the waste gas generated by the reaction is recovered with sodium hydroxide solution Utilizing, the concentration of the sodium hydroxide solution is 0.8mol / L; (4) liquid-solid se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com