Antibacterial foaming insole and preparation method thereof

A technology of insoles and foaming agents, applied in the field of insole materials, which can solve the problems of bacterial growth and insoles that cannot be sterilized and deodorized for a long time, and achieve the effects of increasing hardness, reducing graphene and self-agglomeration, and increasing softness and comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

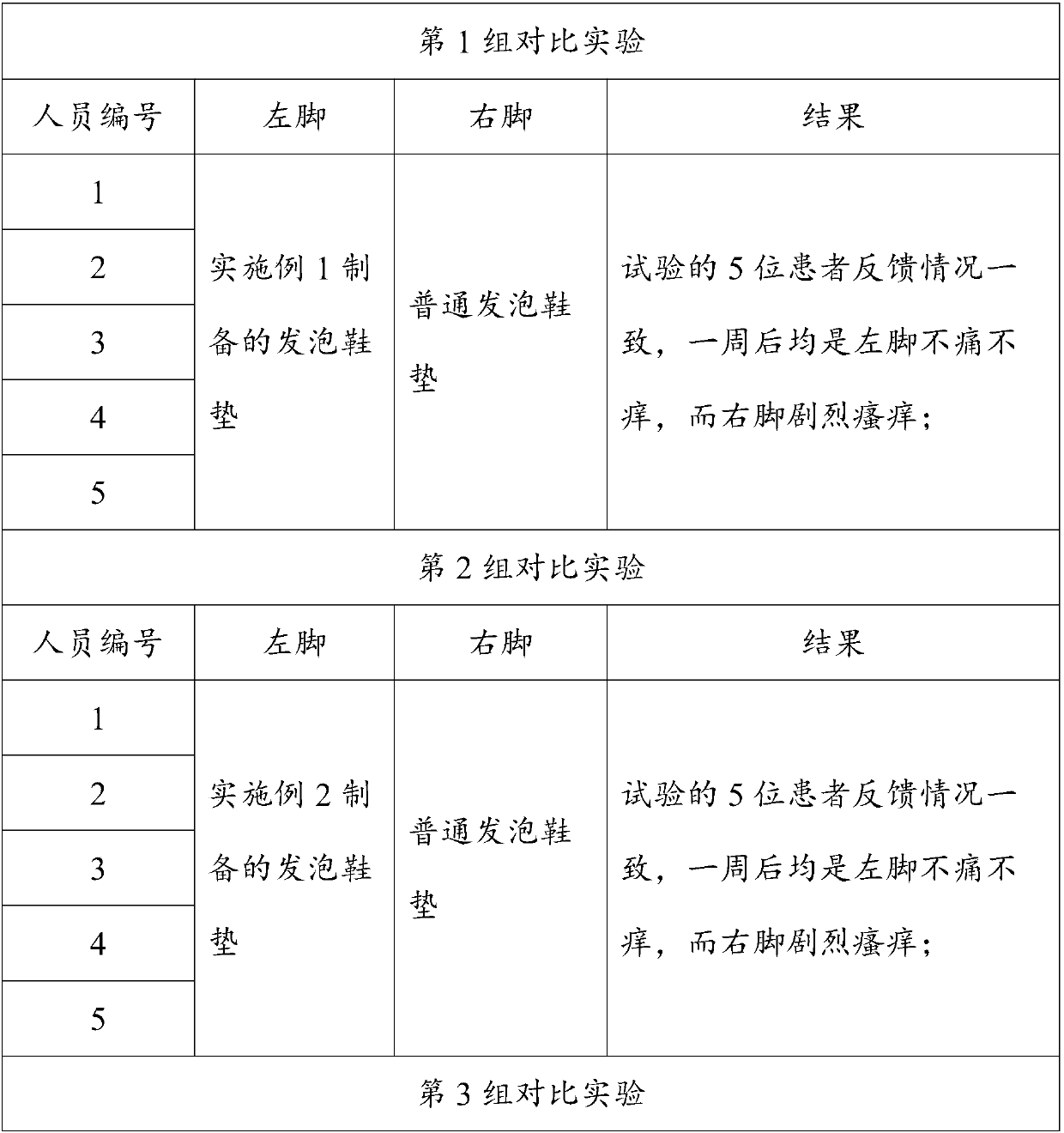

Examples

Embodiment 1

[0020] An antibacterial and antibacterial foamed insole, the foamed insole is composed of 30-70% of main material, 10-30% of filler, 0.5-3% of crosslinking agent, and 0.1-3% of crosslinking auxiliary agent according to the mass ratio of materials. 1%, foaming agent 2-10%, foaming aid 1-6%, lubricant 0.1-2%, graphene oxide or graphene 0.1-20%, silicon dioxide 0.1-10%.

[0021] The main material is any one of ethylene-vinyl acetate copolymer or polyethylene; the filler is any one of calcium carbonate or talcum powder; the crosslinking agent is dicumyl peroxide, and the crosslinking aid is triene Propyl isocyanurate; Foaming agent is any one in azodicarbonamide, 4,4′-bisbenzenesulfonyl hydrazine monoxide, the foaming aid is zinc oxide, and the lubricant is stearic acid;

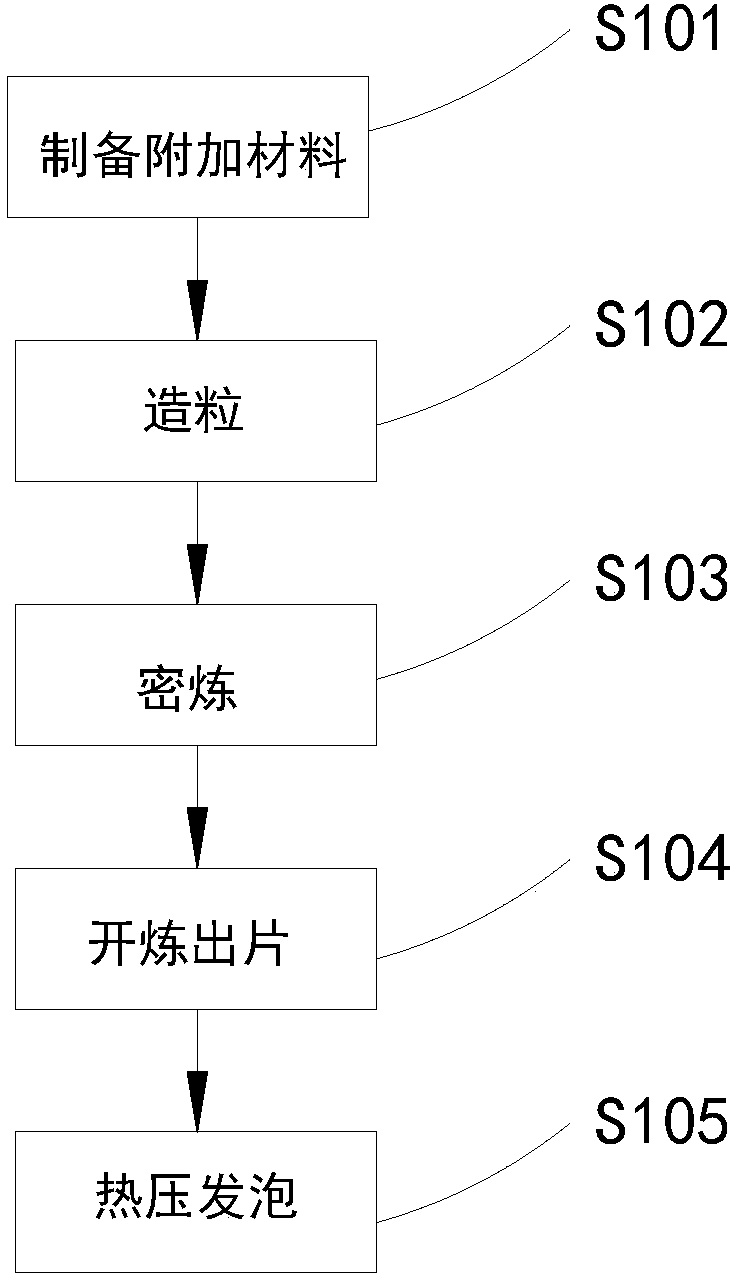

[0022] The preparation process of the antibacterial and antibacterial foaming insole of the present embodiment is as follows:

[0023] Step S101, preparing additional materials:

[0024] The preparation method...

Embodiment 2

[0037] The preparation process of a kind of antibacterial antibacterial foaming insole of the present embodiment is as follows:

[0038] Step S101, preparing additional materials is the same as in Example 1;

[0039] Step S102, granulation:

[0040] Premix 65% ethylene-vinyl acetate copolymer with 5% graphene and 5% silicon dioxide, inject and granulate;

[0041] Step S103, banburying:

[0042] The particles obtained are added into a banbury mixer together with 10% talcum powder, 2% crosslinking agent, 0.5% crosslinking auxiliary agent, 8% foaming agent, 3% zinc oxide and 1.5% stearic acid to obtain For the mixed material, the banburying temperature is controlled at 128°C, and the time is kept for 10 minutes;

[0043] Step S104, refining and producing tablets:

[0044] Put the mixed material after banbury mixing into the rubber mixer to continue mixing, the temperature is controlled at 120°C, the material is mixed evenly, and the pieces are cut into sheets;

[0045] Step ...

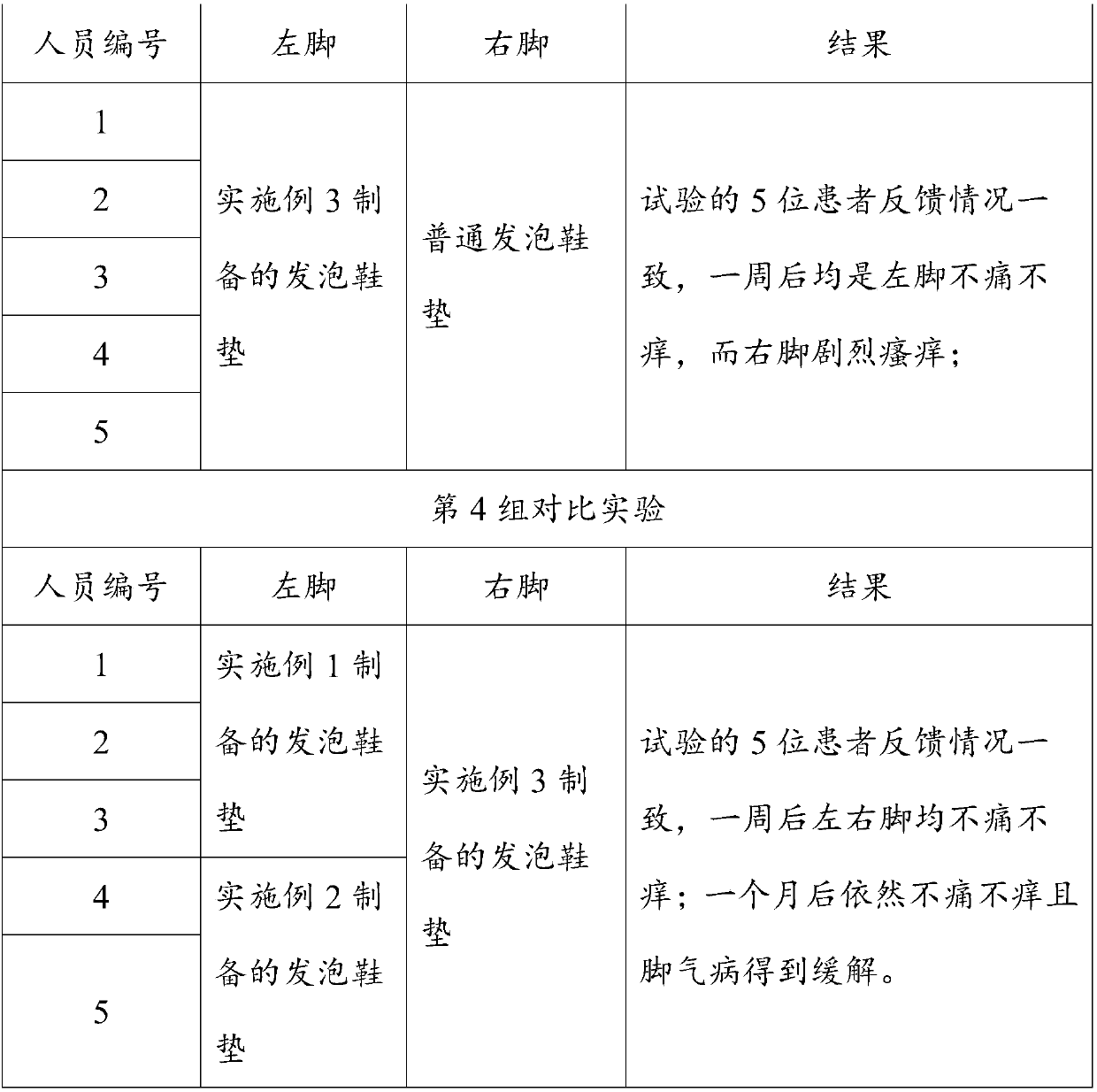

Embodiment 3

[0049] The preparation process of a kind of antibacterial and antibacterial foaming insole of the present embodiment is as follows:

[0050] Graphene, the preparation method of silicon dioxide are with the step S101 of embodiment 1;

[0051] Graphene oxide preparation process: assemble a 250mL reaction bottle in an ice-water bath, add 46mL of concentrated sulfuric acid, add a solid mixture of 2g of graphite powder and 1g of sodium nitrate under stirring, and then add 6g of potassium permanganate in 2 times, control The reaction temperature does not exceed 10°C, stir and react for 1 hour, then raise the temperature to 38°C, continue to stir for 0.5h, then slowly add 120mL of deionized water, continue to stir for 0.5h, add 50mL of hydrogen peroxide to reduce the residual oxidant; then filter while hot, and use 5wt% HCl solution and deionized water were washed until no sulfate was detected in the filtrate; finally, the filter cake was fully dried in a vacuum oven at 60°C to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com